Actually I think Dave was right. There are several factors to consider when using IR camera. First is of course the scaling of colors you mentioned.

Second is that FLIR doesn't measure temperature direcly but IR radiation that can be subject to phenomena any radiation is, namely: transmission and reflection, so measuring temp of shiny surfaces can be tricky (the same is when you are trying to take a photo of a mirror, you not only take photo of mirror itself but also of objects reflecting from its surface). And this happened there on BNC. Camera was showing effect of combined radiation from the BNC itself as well as radiation reflected from eg. Dave's hand.

Third factor is that different materials have different emmissivity coefficients (dependent on color, roughness, etc), so that when measuring its temp you should first set proper coefficient in the camera to make accurate measurements. Thats why, probably, absolute values measured in the video were somewhat off. But in this case it was all about relative temp not absolute.

What you're saying can happen; however, in the case of this troubleshooting video, I respectfully disagree with you. If you look at the video at 31:05, you can clearly see that the scale is at 26.2 max and 22.2 min. The Flir will automatically detect the hottest items within that range and colorize them accordingly. The rest of the video toward the end it appears Dave figured out how to fix the scale to 89.5 max and 25.7 min and that's when you do not see the heat coming from those BNC connectors.

In the video, at 7:24 he tests the bench temperature and it's 24-25 degrees. So you're only looking at a 1.2 degree difference from the bench to the maximum of the Flir scale. The Flir is sensitive enough to pick up that temperature difference in the 22.2 to 26.2 range and show you that the BNC connectors are warmer.

For your homework today,  , try this. Heat up a shiny piece of metal to 100 degrees that is extremely reflective. Then, using a temperature probe of that metal while it is angled toward a block of ice, what temperature would it read? I remember the Mythbusters getting past an IR alarm sensor by using a piece of glass because the unit couldn't "see" behind that glass. They used a similar visual IR heat detection device as well and it was completely the temp of the glass and not what was behind it. So even though I haven't performed this test myself, I would guess the temp it would read is close to the 100 degree side instead of the 0 degree side.

, try this. Heat up a shiny piece of metal to 100 degrees that is extremely reflective. Then, using a temperature probe of that metal while it is angled toward a block of ice, what temperature would it read? I remember the Mythbusters getting past an IR alarm sensor by using a piece of glass because the unit couldn't "see" behind that glass. They used a similar visual IR heat detection device as well and it was completely the temp of the glass and not what was behind it. So even though I haven't performed this test myself, I would guess the temp it would read is close to the 100 degree side instead of the 0 degree side.

I'm afraid gszo123 is bang on. IR emissivity and surface reflections are serious problems when trying to make accurate measurements with a thermal imaging camera. Those BNCs were not warm, it was reflected body heat.

Just for fun, I'd thought I'd try your experiment:

Here's the setup using a saucepan, boiling water, ice, a tub of CarPlan four seasons screenwash and a Fluke Ti10 thermal imaging camera. (Yes, ABELtronics Limited is winding down for Christmas). The highly polished stainless steel saucepan is boiling on my workshop hob. An ice pack rests against the screenwash tub facing the saucepan:

Different angle:

A closeup reveals you can see the reflection of the ice pack in the side of the saucepan:

The water in the saucepan is boiling:

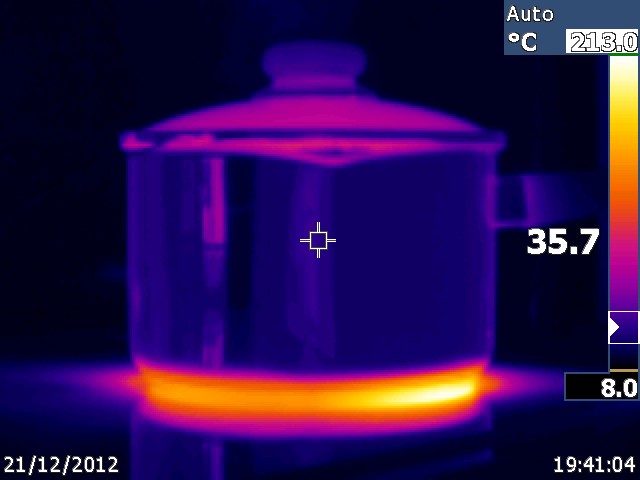

Here's a thermal image of the side of the saucepan. The temperature shown on the right (35.7C) is the temperature of the crosshair in the middle of the image. Note it's a lot colder than it should be (100C) because of the poor IR emissivity of the polished stainless. (The ghostly lighter blue bit right under the crosshair is a thermal reflection of me taking the image):

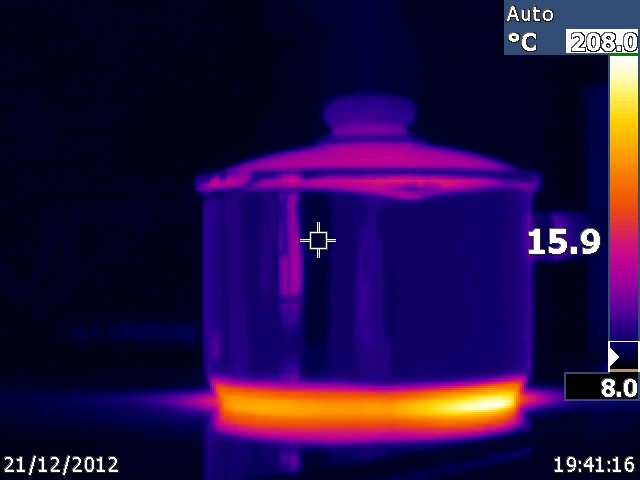

Moving the crosshair over the reflection of the ice shows the TI camera thinks the saucepan is apparently 15.9C at the point where the ice is reflecting. You can see the reflection of the kettle slightly to the left. Remember the saucepan is at 100C:

The ice pack is showing as -0.6C (the warm kettle can be seen in the background):

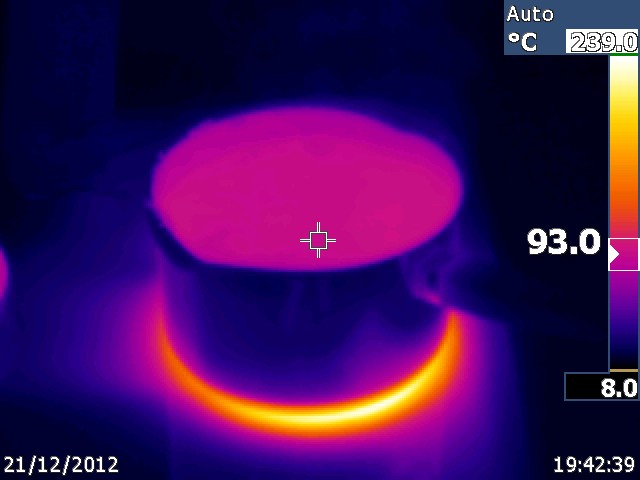

With the pan lid off the TI camera thinks the water is 93C, but the side of the saucepan is considerably colder:

So in answer to your comment, even with a polished bit of metal at 100C reflecting off ice, the TI camera still errs towards the colder end.

Thermal reflections are a problem and definitely are a trap for young players!