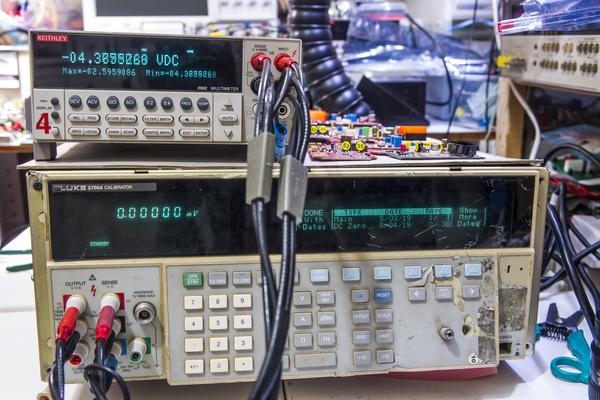

Sudden saturday morning livestream got some progress on "Hulk-2" 5700A calibrator.

I've got it all together to do first calibration attempts. Of course, there should be many hidden issues in this unit, so I don't expect that calibration to stay very long.

Also for more fun, I've used first 5720A calibrator as calibration source for today.

Also upgraded firmware to 5700EP version, which brings GPIB command level to 5720A. This is helpful for me, so I can keep using same python app, developed mostly for 5720A to do more tests in future.

Had to format calibration EEPROM, which is not a problem. Original data in EEPROM is for some other 5700A anyway, not this random mix of board.

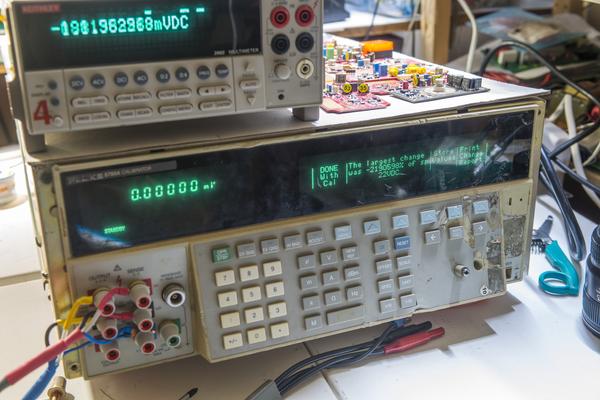

Calibration value shift is only -2190598% off the 24-hour calibrator spec.

No worries, she'll be alright.

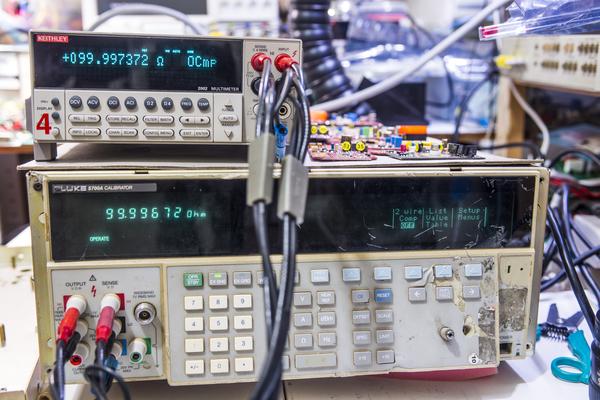

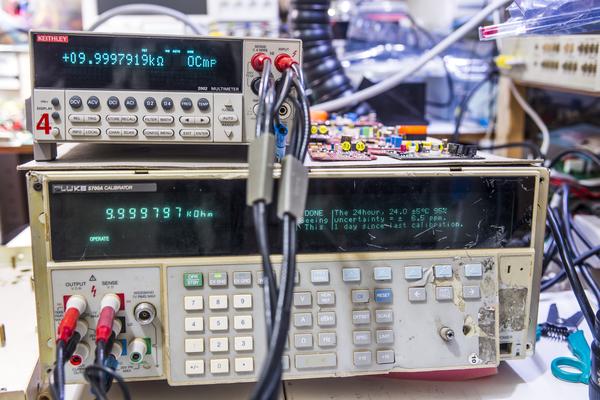

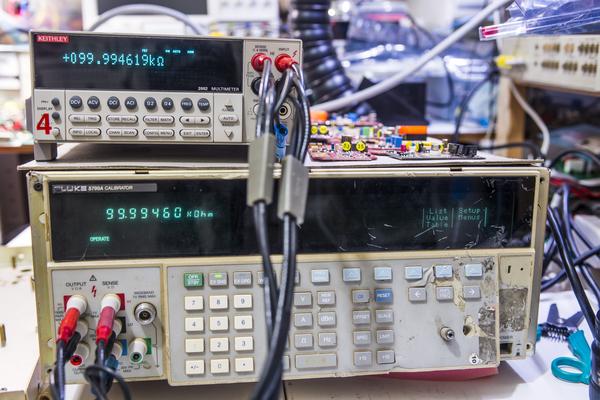

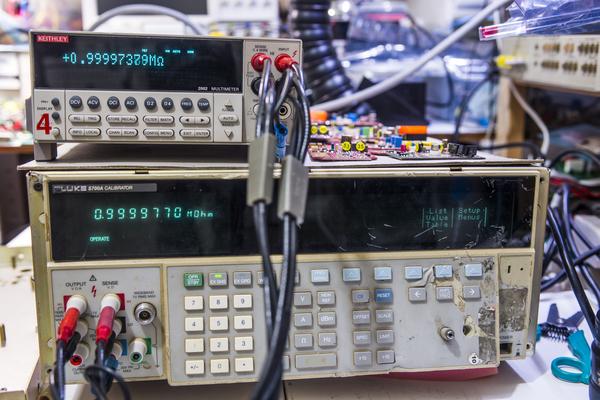

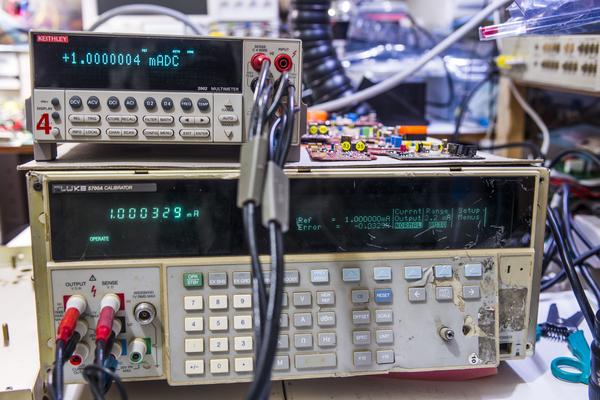

Keithley 2002 will be used as a check standard here.

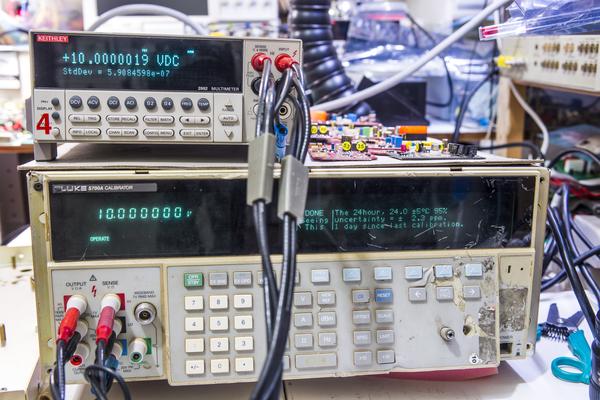

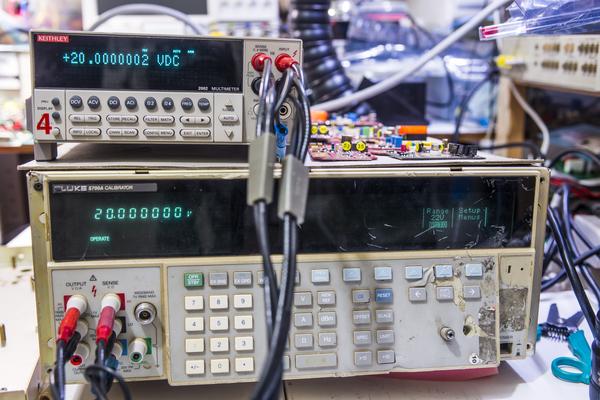

And we got long desired 10V out of the box. Only +0.2ppm off K2002 reading (which is calibrated last year July).

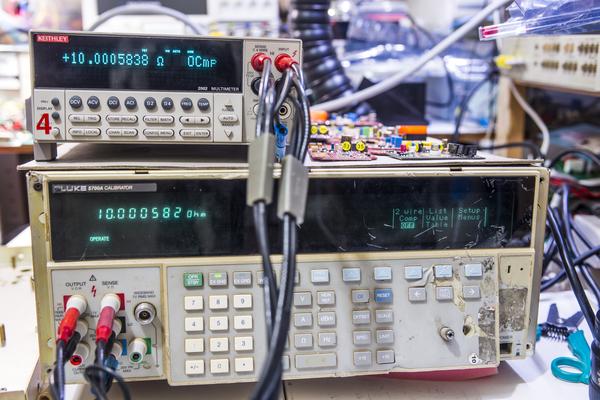

Resistance is nice and happy too. 10 Ohm is +0.2ppm, 100 Ohm is +6.5 ppm.

10 kOhm difference is -0.51 ppm. Calibrator specification for this resistance is +/-6.5 ppm.

Also 100 kOhm is +0.2ppm.

Even 1 Meg is mere -3.2 ppm, very happy with results so far on resistance. Not so much on DCI, there is 330 ppm error (which I expected, A7 current board known to have issue)

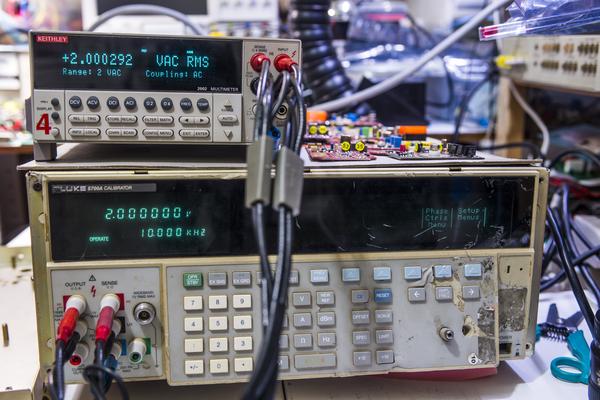

Look at that 20 DCV. Isn't it wonderful? ACV quick check also confirmed operation. Will use

Wavetek 4920M AC Voltage Standard for more detailed tests on ACV when DCI issues fixed.