That's a nice transformer, but not really suitable for a bench power supply.

It's probably 24v AC rms, 80 VA (3.3a) - that means after you rectify it to DC you get about 24v x 1.414 - 2v (on rectifier diodes) = 32v max. and the maximum current would be about 0.62 x 3.3a = 2A

If you'll use a 7805 to get 5v 2A from that, you'll have to dissipate (32v - 5v ) x 2A = 54 watts. That's a ridiculous amount of power wasted, i don't even thing the 7805 is even able to do it.

If you don't care much about ripple/regulation, you can use a LM2596 or a mc34063 with external transistor to get something like 8v 3-4A, then use a 7805 or a pair of 7805 to get 5v 2-3A. This way you'd only have (8v-5v) x 3A = 10 watts, which is easy to dissipate.

1n4007 is only good for 1A, so in a bridge rectifier configuration they can only do 2A. You're better off with a beefier bridge rectifier, something rated for 10-16 amps, they're super cheap.

Linear power supplies are usually made with transformers that have multiple taps, usually about 6-10v dc per tap, and as you adjust the voltage the taps are connected or disconnected using relays to get a voltage slightly higher than needed.

For example, if you want 12v, two 10v windings are connected in series to get 20v and 8v x current value is dissipated on pass transistors.

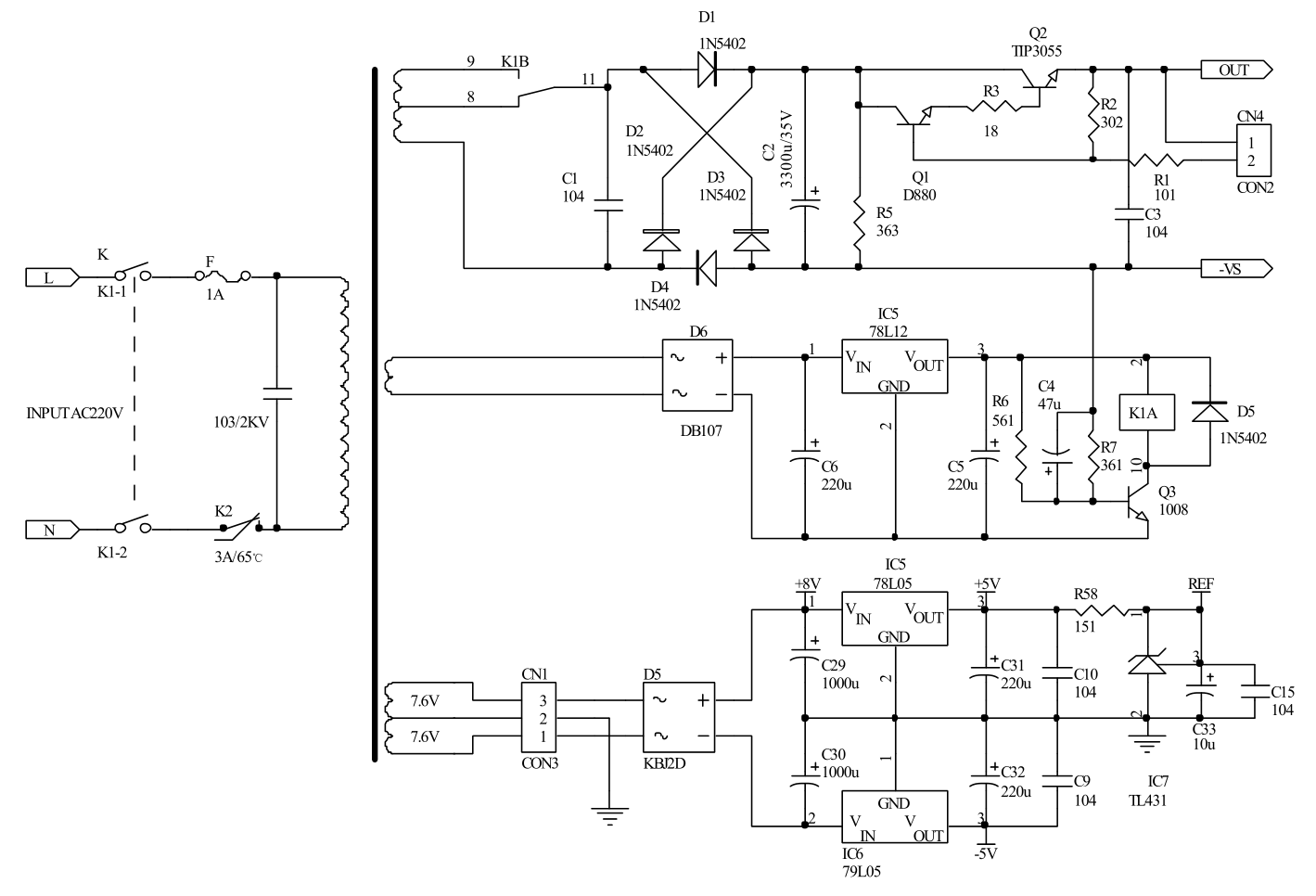

Here's an example of a 18v 2A power supply, using two transformer taps, a separate winding for the relay which enables the second tap or not, and two separate small windings for +/-8v and +/- 5v for the multimeter chips :

transformer, power transistor, linear regulators for opamps , relays, multimeter chips

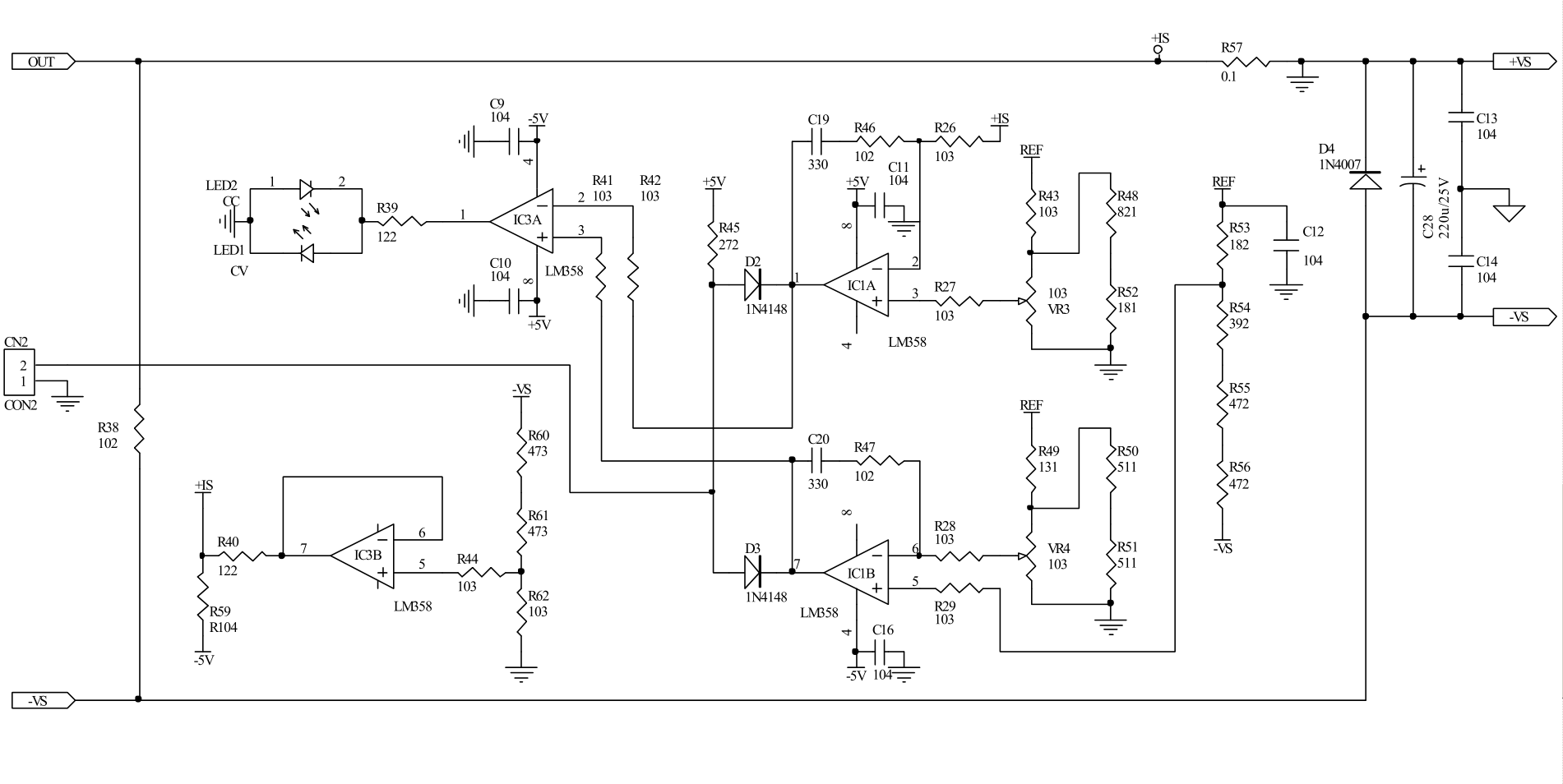

opamp to adjust voltage and current, current limit leds , output ... all jellybean components on this one and the previous part

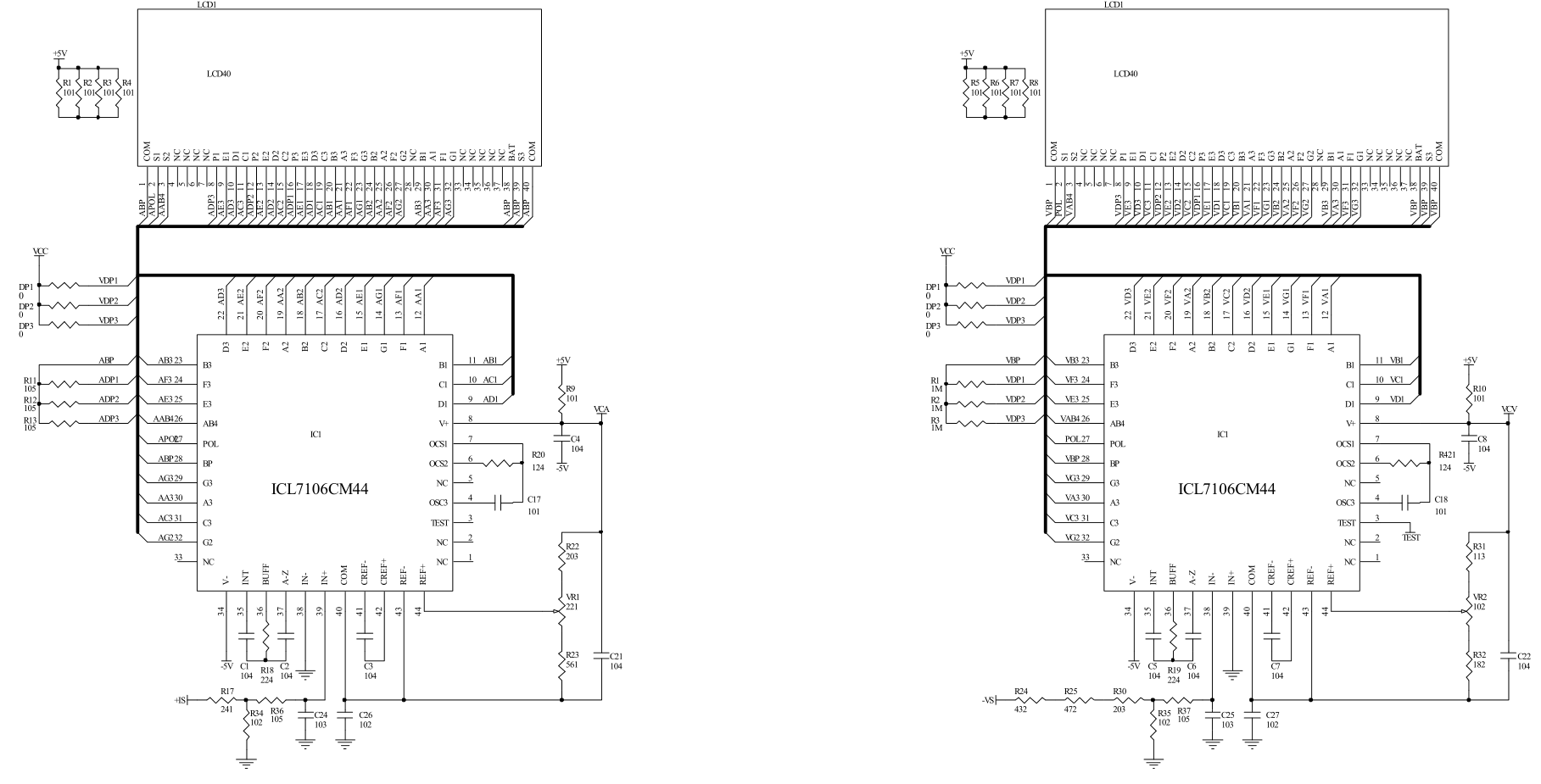

multimeter chips (one for voltage, one for current) ... icl7106 is with lcd segments , icl7107 is with normal led segment (so you could use 7 segment digits)..

this last part is the only slightly more difficult part to make (and the chips are more expensive) but you don't really need it, you can get less accurate ready made meters from ebay. if you do make them, you need some film capacitors and more accurate resistors and you must read the chip datasheet to understand how it works etc..