Now my attention turns to a miniature PC for the Workbench. A while back I kickstarted a

X86 miniPC board by Udoo. I had kickstarted it as an Advanced with 4GB of DDR and a 32GB emmc. At the time I outfitted it with an

80mm Transcend 256GB SSD using a

3D printed bracket I created. I also outfitted the PC with a

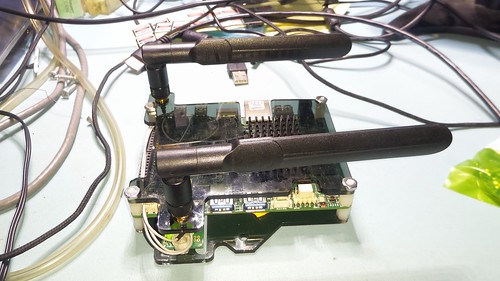

Intel Dual Band AC 8260 WIFI NGFF card and a set of

Wifi Antenna’s to connect to the AC 8260 card. At the time I didn't have any real uses for the board; but knew it would come in handy... Since Intel discontinued the Arduino 101 on the board; I didn't see much point In trying to use it for a maker project.

The purpose of this PC is mainly to look up Datasheets, view Schematics/PCB files, and to run a Windows XP 32 Virtual machine to run my laser cutter's 32bit drivers.

I decided I wanted to create a small acrylic case for the PC and mount it under the new desktop. I did a search on Udoo's forums and found a

opensource case by WalkingRobot. I imported his files; but knew I'd have to modify them for several reasons.

- I had an 80mm SSD instead of the stock 60mm

- I didn't want the complete cut outs for the Arduino 101.

- I wanted to add some WIFI Antenna mounts.

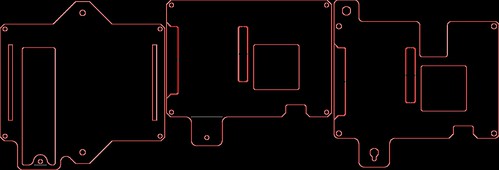

I pulled out QCAD and re-engineered the case for my needs. This was my final CorelDraw file I sent to my Laser cutter:

I actually went thru an intermediate step when I printed the center top... but quickly realized that I need the wifi antennas during final testing.

I laser cut the acrylic case out of some scrap 1/8" smoke acrylic I had laying around from my computer mod days. Here;s the finished case mounted together with some #6-32 standoffs, some nuts, and scome screws:

I mounted it to the side of the drawer so it'd be out of the way from my knees and what not.

The PC is mounted to drawer with some #6 woodscrews.

Next; I turned my attention to how I was going to work with the PC. I need a monitor, hdmi preferably. Turns out I had a monitor arm right there... so use it. I had picked up a small "10 inch test monitor" off of Amazon in Feb of last year. It's intention was to be small so I could debug computers on the work bench... but honestly; the monitor has several killer issues which makes it difficult to use. 1) it's bezel is too big; so things like the windows start button get cut off. 2) it doesn't like the early boot mode of the udooX86. It's really can't be used in bios settings; only when the system is booting and when the resolution has been "shrunk" to fit within the bezel. But it was cheap-ish... so might as well use it. If I were buying a new monitor for this rig; I'd probably go with something like this:

11.6 1920x1080 display with 10point touch.

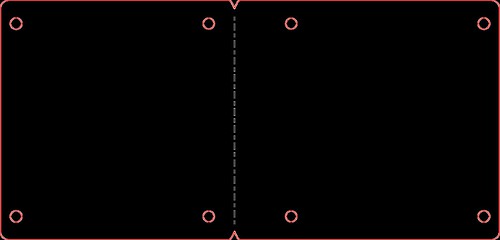

I wanted to mount to my scope's new monitor arm; so I created a right angle 75mm bracket in QCAD and laser cut it:

Using a heat gun and some clamps; I bent the bracket at the dotted line:

and mounted it with the leftover amazon hardware and some spare 4mm nuts I had on hand:

I then mounted the monitor to the bracket using some additional 4mm hardware:

I didn't want wires on my desk; so I ordered an hdmi cable and fed it thru monitor arm. I had an older

Logitech Bluetooth keyboard and a

Logitech BT mouse that I acquired over the years. Both paired perfectly with the Intel AC8260 card's Bluetooth radio:

Finally; I paired the PC w/ a

bluetooth speaker so I can stream some music while working on projects.

The PC runs pretty good for only 4GB of DDR. I do want to upgrade the monitor to the one I pointed to above... but I've been spending way too much cash on this project to date.

Incidentally; I did get my Resistor and Inductor pulls in from shapeways a few weeks ago. I also risk-ordered the pulls in nickel, polished, stainless steel because Shapeways was doing a small percentage off sale. Here's the pulls printed in White Processed Versatile Plastic:

They look good; but for some reason the tapped holes were not #10-32 as I had thought I designed... but closer to #6-32. As a result; I'm about 95% sure the metal pulls will show up with the smaller holes.

The metal pulls shipped a few days ago... so hope to have them in the coming days. I've already started working on my drawer faces... I'll post more pictures when I get them finished.