Hello folks,

This topic has been discussed but didn't find any conclusion - Wondering if I could get a hand. Looks like a simple thing but I'm running out of ideas;

I'm trying to drive this aircraft instrument:

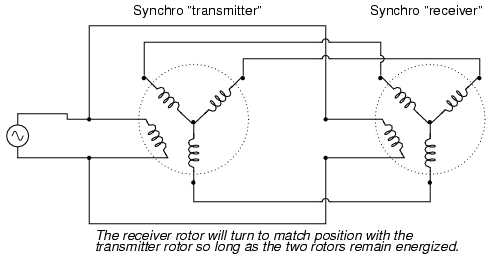

The connections inside it are like this:

That is, one of the terminals on the rotor is connected to one of the terminals in the stator.

Knowing the waveforms generated when the rotor is excited, as per:

What I tried so far is connecting half-H bridges to each one of the terminals (1,2,3,4), and drive them with a PWM-based Sin as follows

1) and 2) are complimentary outputs of generator 1

Generators 1, 2 and 3 share same timer, so same initial phase and frequency.

I drive all outputs with a 400 Hz sin, modulated as follows, being alpha the desired pointer angle

PWM1 = sin(alpha)*(400Hz signal)

PWM2 = sin(alpha+120)*(400Hz signal)

PWM3 = sin(alpha+240)*(400Hz signal)

What it's confusing me is the fact one of the stator windings is tied to one of the rotors.

With this setup, I get some movement but it's not OK. On this video, I'm moving the desired angle from 0 to 360:

I tried this setup with two similar instruments:

and the current consumed by both synchros was about 80mA. On my experiment you can see power supply is limiting the current to 300mA, so something's not quite right.

Ideas?

Thanks!!