I guess that if I were you I would run exactly the same profile that I did... then we can start looking for the differences.. firmware version, thermocouple, cold junction... board version... I guess Id like to see a plot of your data. Im not sure what you mean by "wild temperature profile"

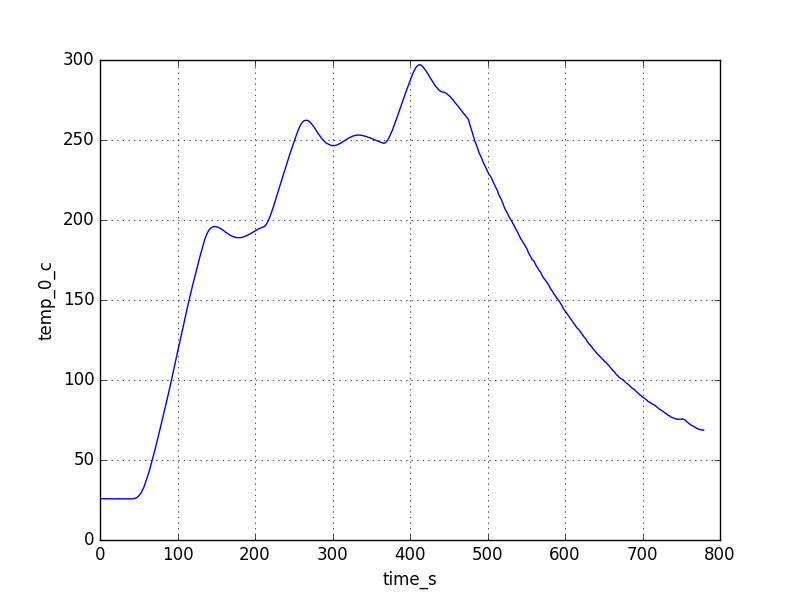

I still had some test data left on the logger's memory card. Here is a plot with the thermocouple taped to the top of the board, using the oven's default temperature profile:

I just plotted one channel there, but the measurements were pretty consistent at the other three locations I probed. Measured temperatures were a lot higher than the profile settings, with big overshoots at each step. Next time I work with the oven, I'll take better data, including logging the actual profile settings. If I recall correctly, the setting for that first shelf, just under 200ºC, had a 150ºC setpoint. The soak stage ended up well above reflow temperature.

I would be open to working on an open source oven controller to retrofit into that oven....

Unless we identify a serious problem with the controller card design, I would be more inclined to want open source firmware for the original controller. We could clean up the user interface for English-speaking users, and maybe add options such as running the fan slowly during soldering to even out hot spots in the oven?

Do you think that the design of the IR tubes is correct? i.e. is the platform sound sans temp measurement.

I don't have enough experience with these things yet to form much of an opinion on that. I certainly like the QS-5100 platform more than the T-962 platform, but even the inferior (in my opinion) T-962 platform appears to be giving many people good results after being modified and upgraded.