Acquired recently this scope at local tech surplus store, and even its quite old now, still, it should be pretty good piece of equipment. Among peers & friends here, we called this Jim's scope cause Jim Williams (in memoriam) used it too at his personal bench table.

I have another similar thread, but its for asking some details ->

https://www.eevblog.com/forum/index.php?topic=5258.0 , and decided to post the teardown photos in this new thread instead of there.

Here we go, teardown and preliminary inspection, since I'm going to recap the whole scope and took shots for documentation and component inventory purposes.

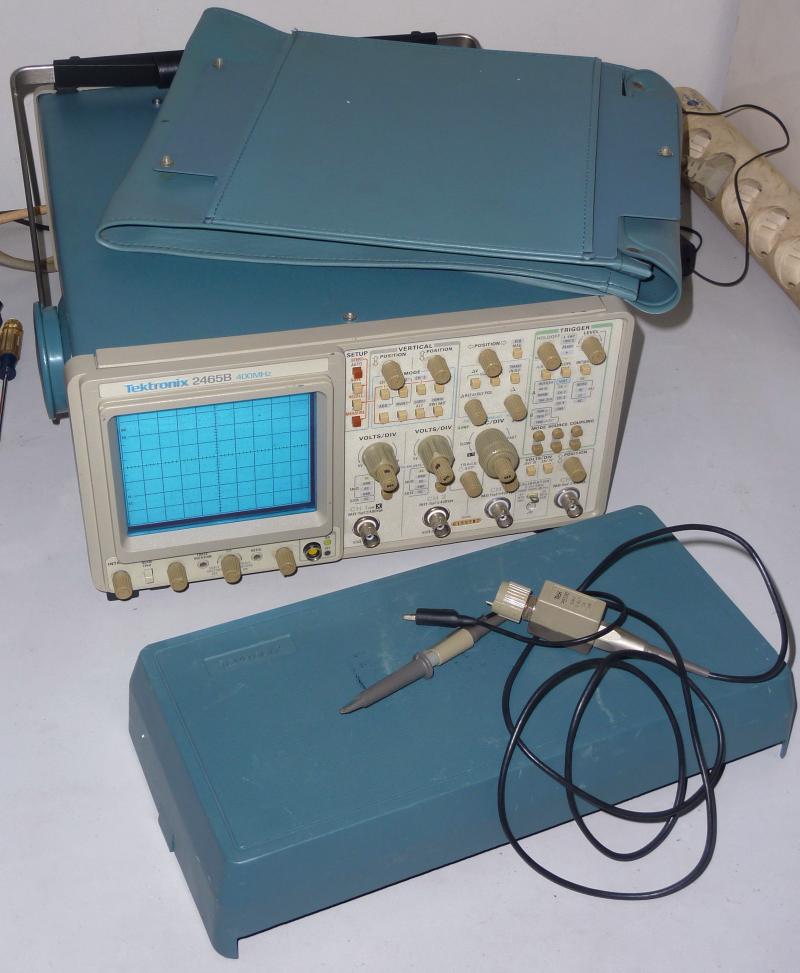

The whole bundle, with the top pouch, front cover and a single Tektronix P6136 350Mhz probe. Every thing is nicely preserved by previous owner, I was told it was previously used in clean r&d lab at a big consumer electronic factory.

Click to enlarge the pictures.

With front panel facing down, and main cover detached, the rear, top and left sides view. Top and left are covered by aluminium plates, these are HV and power sections.

With top cover opened. Wait !! It looks so empty and spacious ? Is that it ? No folks, these are just the crt tube and the main power supply only. The middle module has two separate pcbs, which are linear and switching part placed side by side isolated by a thick metal plate. Both supply the power for the whole scope. I guess they opted to place these noisy parts crt & psu in the middle isolated room to reduce hf noise.

The bottom and the right sides view, still standing vertically at it's face, look at the view, now we're talking.

Bottom part is the main board for all analog stuffs there, while the left board is for the logic, cpu and control. What interesting about this view is, the big main board is using through hole components, while at the control board is using smd. Probably this was designed and made during the transitional period from through hole component to smd style.

The main A1 board, handles all analog stuffs here. The middle black zigzag stick is connected from the main power switch at the rear to the front panel power button. All components are using through hole style.

The A5 logic & control board, made it portrait view for better detail, almost all are using SMD components.

The left side view without the metal cover, high voltage crt power supply and the horizontal & vertical control board at the middle.

The power supply linear part and the main rectifier at the left side, while with switching part at the other side encased inside aluminium box. Few classic and popular to-220 linear regulator ICs are bolted at the bottom with thermal pad like LM 317, 7805.

The rear cooling fan without it's holding metal bracket, very noisy and it will be replaced with new & better fan. Also it's cables termination will be replaced with small 2 pins ordinary fan connectors for easy detaching it for cleaning and maintenance in the future, instead of permanently soldering them directly at the terminal (see inset).

Another interesting finding is the fan's date code 9605, it has the latest date compared to other components throughout the scope, looks like its 1996 or later made. Anyone know what year Tektronix stopped releasing the 24xx model ?