Another Fun Project: Print #790 Servo Saver Hub & Servo Mount https://a360.co/35zf0Nv

https://a360.co/35zf0NvSo the slow boat from China finally surrendered my latest order from TomTop; a

FS-GT3B 3-Ch surface transmitter and the rest of the bits & bobs to convert my WLToys 4WD RC Truggy to fully "Hobby Grade" electronics with separate RX, ESC, and normal 3-Wire steering servo. I have one of these in the trailer held hostage against the Canadian Bureaucracy; someday I'll see it again...

These are one of the best non-telemetry RC transmitters ever made; easily modded to ball-bearing action, and if you're not afraid of a little JTAG action, it can be reflashed with one of the

best-developed alt firmwares out there.

This car uses a bit of a oddball slim servo; nothing available on Amazon is a direct fit, and most standard size servos won't even fit between the base uprights, so I ordered the closest TomTop had which happened to be also metal gears for a whopping $4. I figured worst case, I'd use the controller PCB to convert the stock 5-wire servo to a proper 3-wire signal. When it got here, I was actually quite impressed with the strength and speed of the servo, and build quality appeared very good as well, with even hybrid brass/steel gears in the last 2 gear stages.

However... (there's always a however

-group-therapy-thread/?action=dlattach;attach=1021934;image)

) it wouldn't quite fit in the original servo mount, and even as close as it would go with ghetto-fab mounting, the geometry was wrong to fit the OEM fixed-length steering links. Oh, and it has an oddball 21-spline output shaft, which is probably why it was on sale for only $4, so no go on the servo-saver.

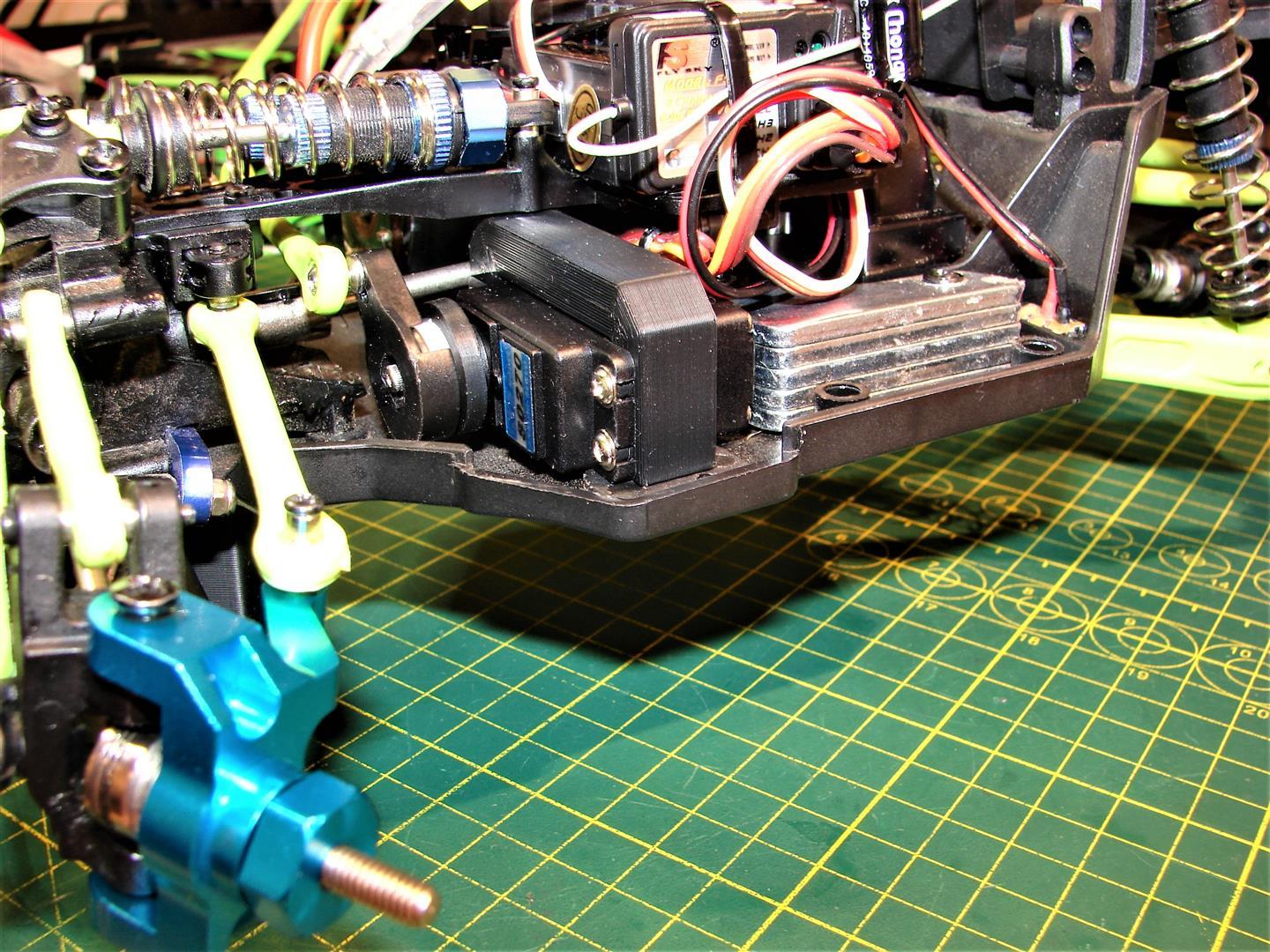

I fiddled and futzed around with the regular servo horns that came with, but even they refused to cooperate... so finally, I gave up and decided to take the time to design and print these parts. The servo mount was pretty straightforward; just direct measurement to make the correct offset so the servo hub is in the same location as stock.

The servo saver hub was actually a lot easier than I thought it would be though; all concentric circles, and I was able to keep them in order in my head for the pushes & pulls to make the shape as needed, and I was able to make the base flange a little extra thick so more meat around the output shaft area.

This was the output of my CR6-SE at 0.12LH with 0.2mm nozzle; the precision on both outer and inner dimensions (even holes, which I've always had to fiddle around with the get anything even close to an exact diameter) is effing amazing.

I guesstimated on the necessary diameter of the hub opening and got it right the first try; I dismantled the servo and took the output gear, then after screwing an extra-long m2 screw through the hub as a pilot, I was able to press the brass shaft into the printed hub with my soldering iron, melting the correct splines into the printed part for a perfect fit. This worked astonishingly well; a quick squirt with alcohol to make things cool quickly and the part slipped off snug but perfectly intact!

And here it is all assembled; I've packed the gearboxes with light PTFE grease, so now all that remains is to replace the axle hubs and drive hexes with the bling parts. And then do that again on my son's car.

Hub Printed on my Creality CR-6SE in FLASHFORGE Brand BLACK PLA; 0.12LH, 0.2mm nozzle, 60mm/s, 200°C/60°C Bed, no adhesion, no supports, infill set manually to 1mm grid, 0.8mm top/bottom 1.2mm wall thickness, with combing & bridging mode enabled and part rotated to benefit bridging. Bracket printed same settings, only 0.20LH/0.4mm nozzle.

Hub Printed on my Creality CR-6SE in FLASHFORGE Brand BLACK PLA; 0.12LH, 0.2mm nozzle, 60mm/s, 200°C/60°C Bed, no adhesion, no supports, infill set manually to 1mm grid, 0.8mm top/bottom 1.2mm wall thickness, with combing & bridging mode enabled and part rotated to benefit bridging. Bracket printed same settings, only 0.20LH/0.4mm nozzle.mnem

vroom-vroom!