Hello!

I am trying to analyze some layout solutions aimed at reducing the button reflection effect (especially with 74HC14 IC).

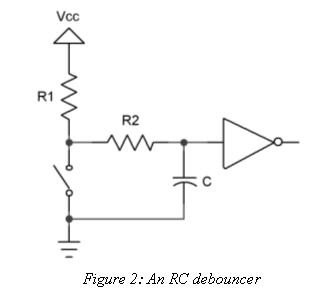

I will use one of the most common system solutions from the internet:

I am aware that eliminating debouncing by software solutions is the most flexible solution to the problem anyway. However, insisting on this circuit, I am thinking about the type of capacitor.

A schematic like that suggests that when the breaker is closed, the capacitor will discharge through R2. The capacitor, by maintaining some potential on the line for a while, will mask any bouncing of the switch.

My question:

The use of a capacitor, as well as the nature of the disturbance it is supposed to eliminate, would suggest that it should be a polarized capacitor with quite a large capacity.

Meanwhile, I often find diagrams with a non-polarized capacitor. Even without a capacitor discharging resistor, with which it lives in symbiosis and determines its discharge rate. If we can afford the circuit for reducing debouncing effect, why not use, for example, tantalum capacitors instead of 100nF ceramic, which is sensationally often seen on ready-made PCBs?