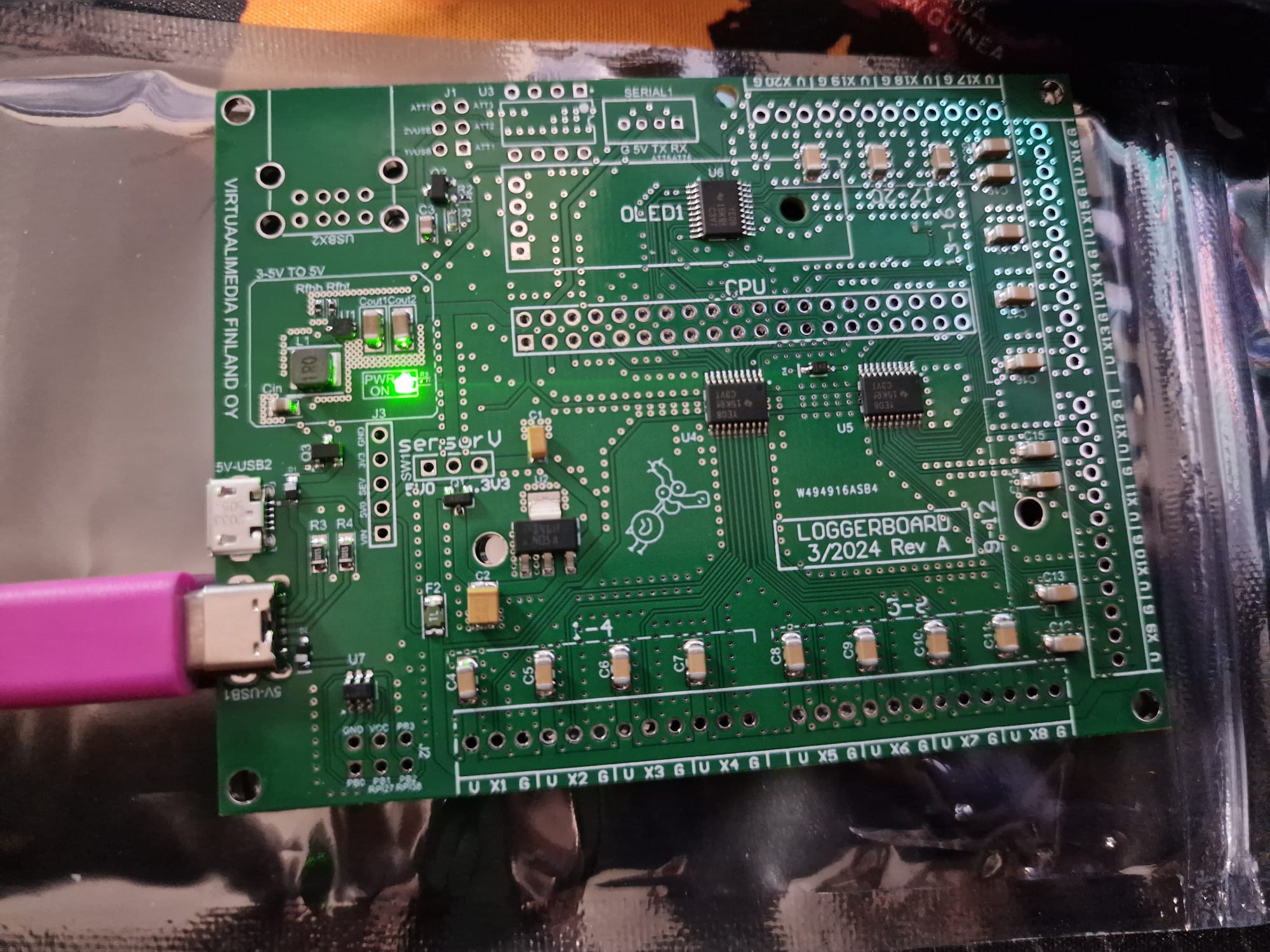

My first PCB design with SMD components pre-assembled in pcbway went south immediately. (Magic smoke...)The pcb is basically a breakout board for a Pi Zero to connect 20 DHT22 sensors, but with 3-5V to 5V boost converter for external power and selectable 3.3V or 5V sensor voltage.

- It also has level shifters for data lines coming from sensors to gpio.

- Attiny10 smd microcontroller to have full system and sensor reboot possibility.

- Place for dual usb-a connector with power on-off possibility.

I ordered 5 boards from pcbway with smd components and usb-c and micro-usb connectors assembled. I want to solder through hole stuff my self but I did not solder those yet.

I just got the boards. Before powering on the first one I measured that nothing was not shorted and it looked good. Then I connected the usb-c connector to my phones usb charger.

1. First the power on led lit nicely and I was able to measure that the input was 5.125V and after the boost converter it was 4.999V. No problems. (The only thing consuming power at the pcb at this point was the small smd led.)

2. I then proceeded to carefully try to feel out if any component was overheating by just gently touching the top of the components. At this point the smoke came out of the feedback resistor of the boost circuit (Rfbt). (CRCW0402732KFKED CRCW Series 0402 0.063 W 732 kOhm ±1 % ±100 ppm/K SMT Thick Film Chip Resistor).

3. I disconnected the usb power immediately and started searching for shorts but found none.

4. I measured the second pcb for shorts and continuity on power traces.

5. I connected power to the second board thinking the probem with the first could have been a manufacturing flaw. -> Smoke from the input protection diode (D1) between the usb connector and the boost circuit.

6. I have been trying to find the flaw for two days now but cant find one. I already got smoke from third pcb and this time it was the p-mosfet (Q3) after the protection diode before the boost circuit.

All help is appreciated.

Pictures:

https://1drv.ms/f/s!AnfIOtcTpP6Bg4Njyl16cHLvhViyuw?e=eCatYSLink to circuitmaker project:

https://365.altium.com/files/C33BBF2E-E81A-4FCC-8011-A663D419CE9AProject files archive: (corrected)

https://d3mo.fi/storage/Pi_zero_20sensor_2024_03_25/What tools is have for debugging:

Fluke multimeters, lab power supply, frequency generator, soldering equipment, internet.