As if there are not a zillion of these threads already...

Anyway, now that I have completed a large car project that has been a few years in the making, I am dabbling back into some electronics fun. Or at least non-car related electronics projects. This all started out as wanting to design a new ring light for my binocular microscope that I use for rework, soldering, inspection, and other stuff that one might find a microscope useful for. The cheap "80 LED" ring light that I was using had met a hot and smelly end when I over-drove it with my bench PSU lol...it was not really bright enough with the stock AC-DC converter onboard, so I drove it directly from a variable DC supply up until I got a little too excited with the output level. While there are plenty of inexpensive ring lights out there, they all use junk white LEDs with awful spectral coverage. Aside from this being a little straining on my eyes, it also makes for lousy digital photos when I have the camera attached.

So, I set out to design a much nicer ring light using some Bridgelux BXEN LEDs which have some of the best spectral coverage of any white LEDs out there. As part of the over-designing fun, I took thermals fully into consideration and the PCB is 2oz copper on an aluminum board, with generous copper pours for all of the LED pads and the LED current driver ICs. Hand soldering is not going to be a thing here. Of course, a hot plate and heat gun would very likely suffice for this simple board, but I'd really like to adhere to the specified reflow profile limits in the LEDs' datasheet to avoid messing up the output spectrum since that was sort of a central design consideration that kicked all of this off. That, and I plan to make a fair number of LED strip modules with aluminum boards for workspace illumination, so I will need a good way to do a large batch of those.

With the background pedantry out of the way, here's the part that has to do with the thread title. I spent several evenings looking up what people have been doing for converting toaster ovens into reflow ovens. Lots of pro's and con's all over the board. The general consensus seems to be that you can DIY a better reflow oven for the same cost as many of the AliExpress-type commercial offerings, at least if you take some time to think through what you are doing. I do not have the space or money for a proper hot air or vapor phase reflow oven, so I'll be doing the best that I can going down the toaster route. This is a hobbyist operation over here, not a commercial endeavor.

The first challenge was simply to find a suitable toaster oven. The Controleo3 solution is well documented and has some good recommendations for ovens, but I want a slightly larger oven which could (at least in theory) handle a 305mm (12 inch) long PCB. Yes yes, thermal stratification and all that...I'll see how things look when I get there. Trying to identify a suitable oven online was proving to be challenging since many models / listings have no information about the power draw, number of heating elements, or type of heating elements. Aside from the ~305mm internal width criteria, I also decided that the oven should have quartz heater tubes, preferably 4 of them (2 top, 2 bottom), and a power draw of at least 1400W. Ultimately, I just went to a local home goods store and started poking around in the toaster oven aisle. It probably isn't every day that they get someone poking a tape measure into toaster ovens lol.

Thankfully, a suitable candidate was present, in stock, and even on sale for the reasonable price of US$69.99. It had a convection function, which I was sort of ambivalent about since it sounds like that can be a double-edged sword, but all other requirements were met so I figured that I could decide later whether or not to use the fan.

NOTE / TO-DO: Post internal dimensions of oven for everyone. Will do in a future post. Very roughly, the internal volume is ~18L, and will probably be more like 16L after walling-off the rear "pizza bulge."

Ladies and gents, behold the majesty of the Hamilton Beach model 31418.

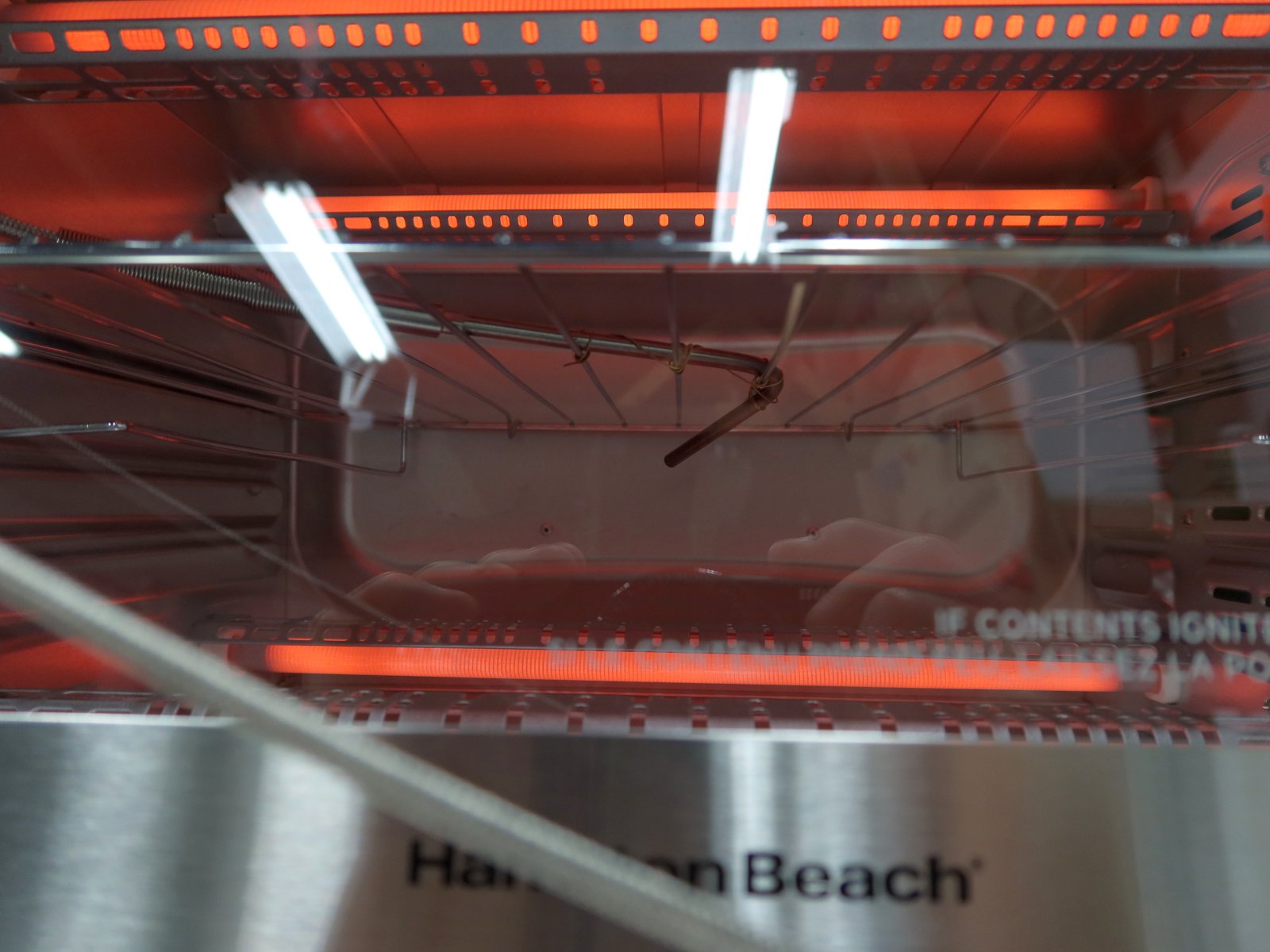

The first task was to crank this beauty up to the highest temperature and let it dwell (in my garage) for a good hour in order to release the enticing musk of burning oils and plasticizers from its supple frame. All 4 heaters looked to be working as expected. It did not smoke at all, but let's just say that I would never put food into one of these without first doing an initial burn-off cycle.

Power draw after 10 minutes was about as-rated. After an hour, the draw seemed to level out at 1490W, probably due to metallurgical changes in the heating coils or something.

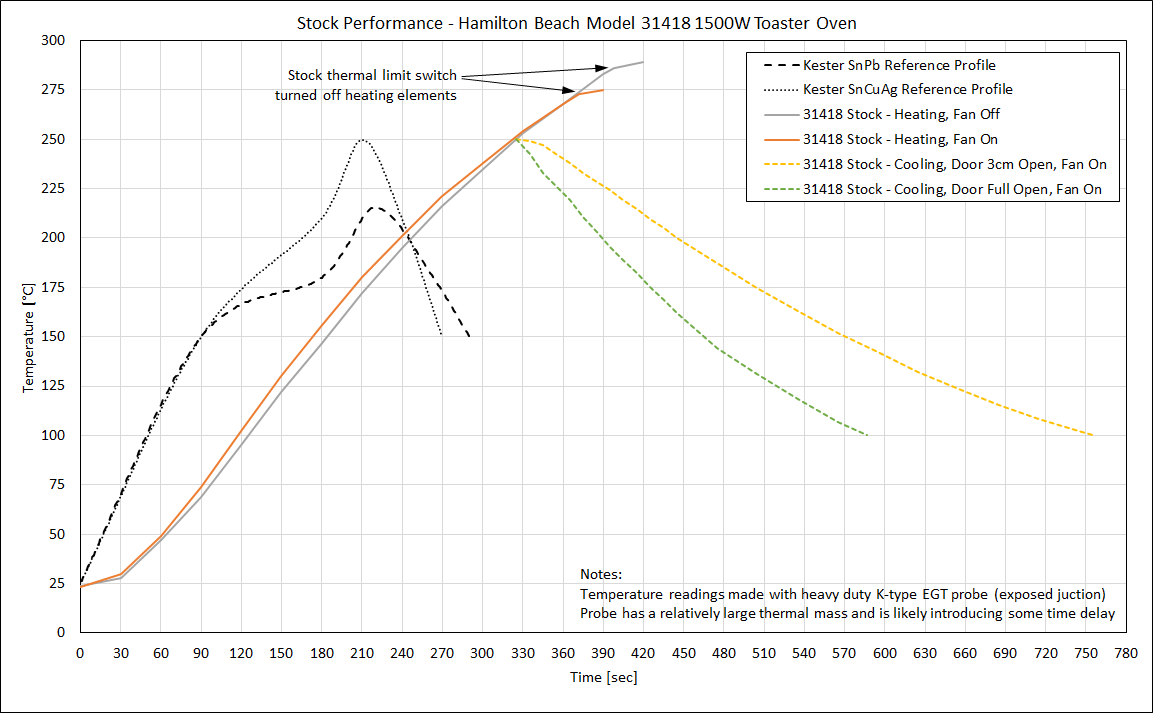

The next order of business was to do some really rough performance characterization on it before hacking it apart. I had some K-type EGT (exhaust gas temperature) probes sitting around since they are going to be used in a future car project where I convert to an aftermarket ECU and will need to do a lot of tuning on a dynamometer. The probes are intended to handle considerably higher temperatures than what this oven can produce, and they were all that I had on-hand to use anyway. Better than nothing.

Now, take the values with a grain of salt. The EGT probes are not made with SLE-grade thermocouple alloys, and I had them plugged into my handheld Keysight DMM where I was taking readings visually next to a stopwatch. I'd guess that the absolute values are within 10°C of actual. The EGT probes have a relatively large thermal mass, even with the exposed junction, so this probably introduces several seconds of lag in the readings. At the same time, this might help things get a little closer to what an actual PCB would see. Much later on in this project I will actually check this on a real PCB with some 30ga K-type thermocouples, but that is a long way off.

Overall, I think that this unit has sufficient power. The system is too slow in heating and cooling, but that should change with proper insulation. The little convection fan does very little overall as far as I can tell. There is also a ~30 second lag when you first turn on the heaters. They are reasonably large and have their own thermal mass. So, really the curves could shift left in time by about 30 seconds. It still isn't any good for an actual reflow profile, but it is closer to the target at least.

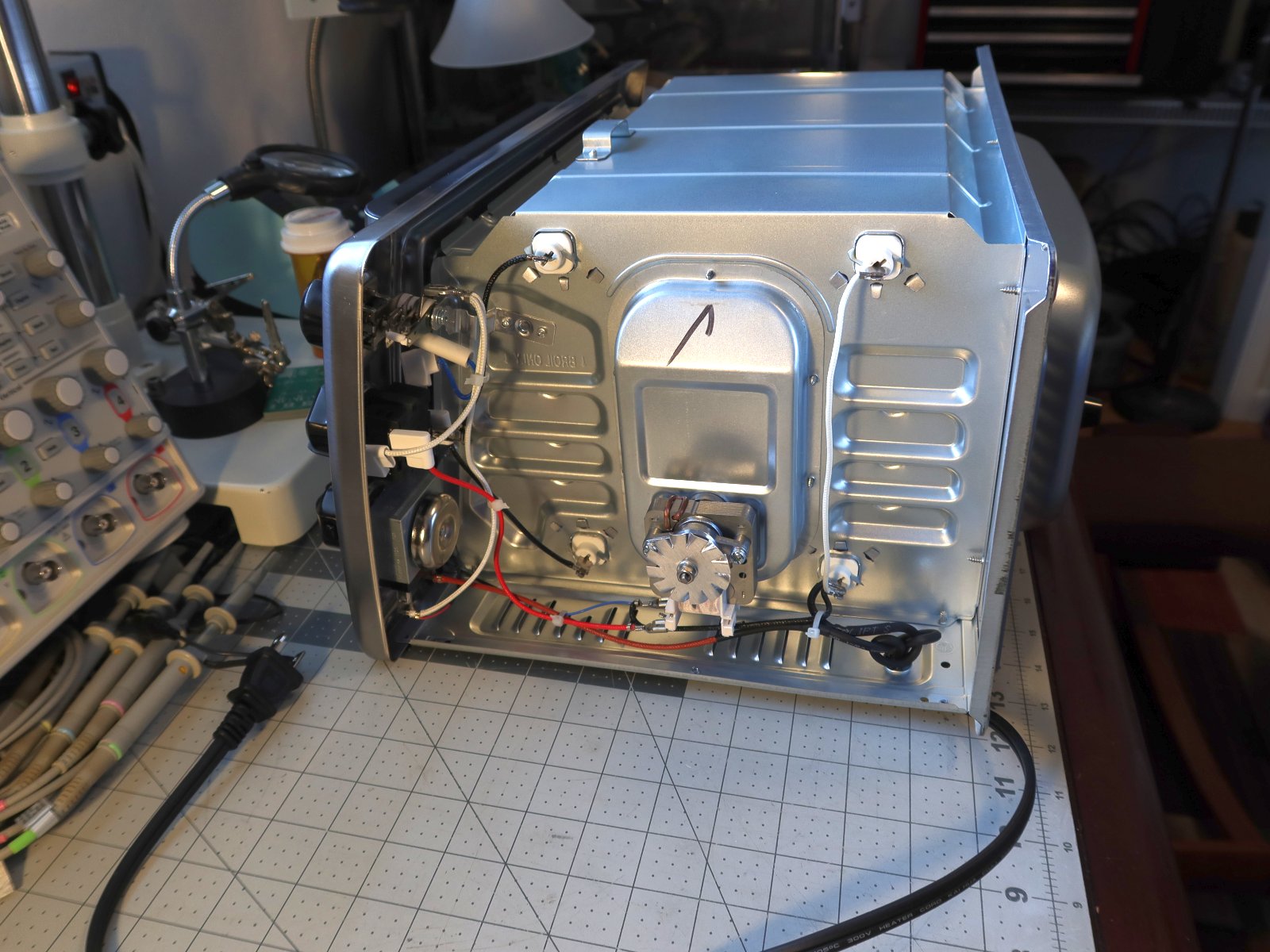

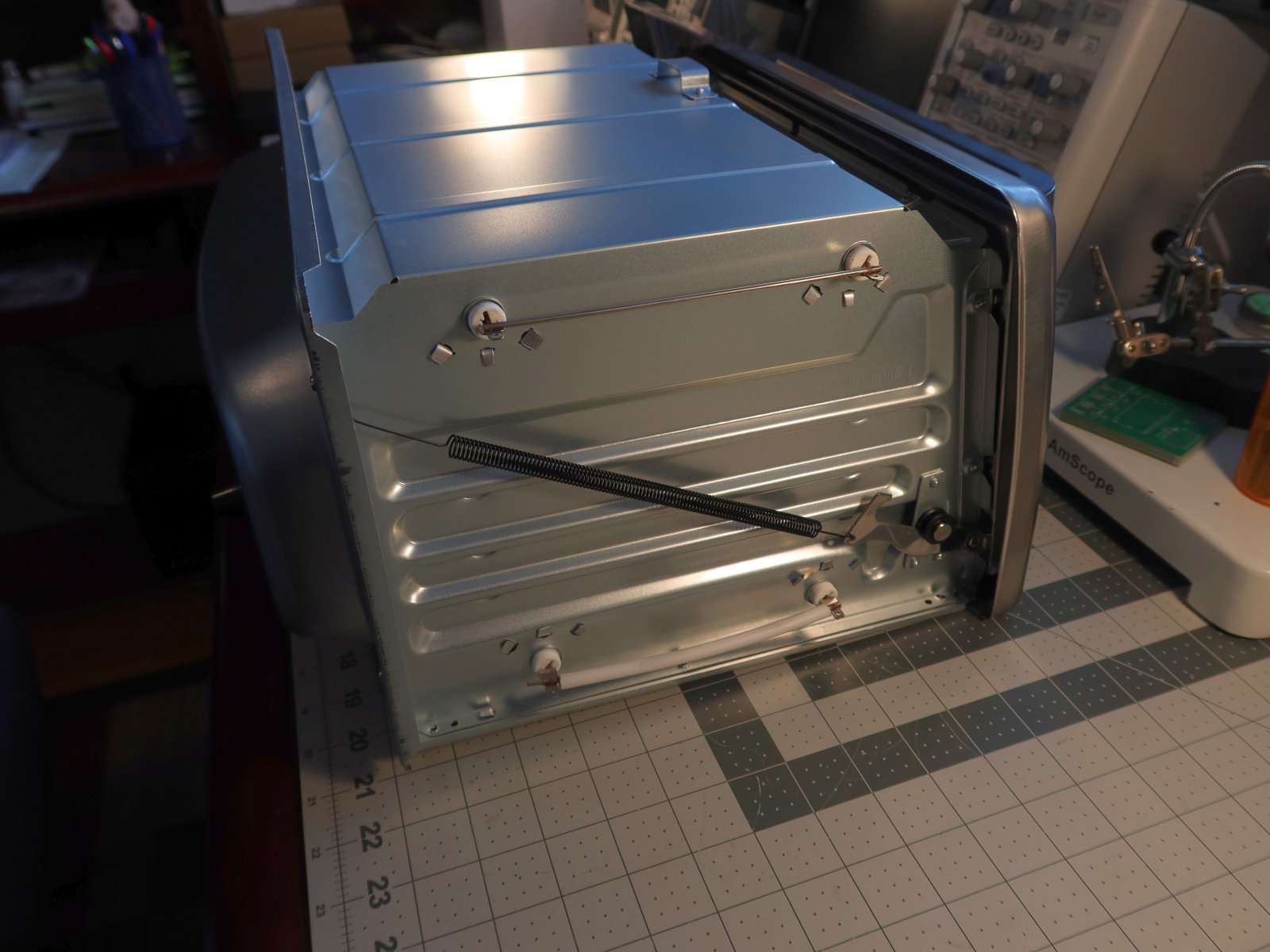

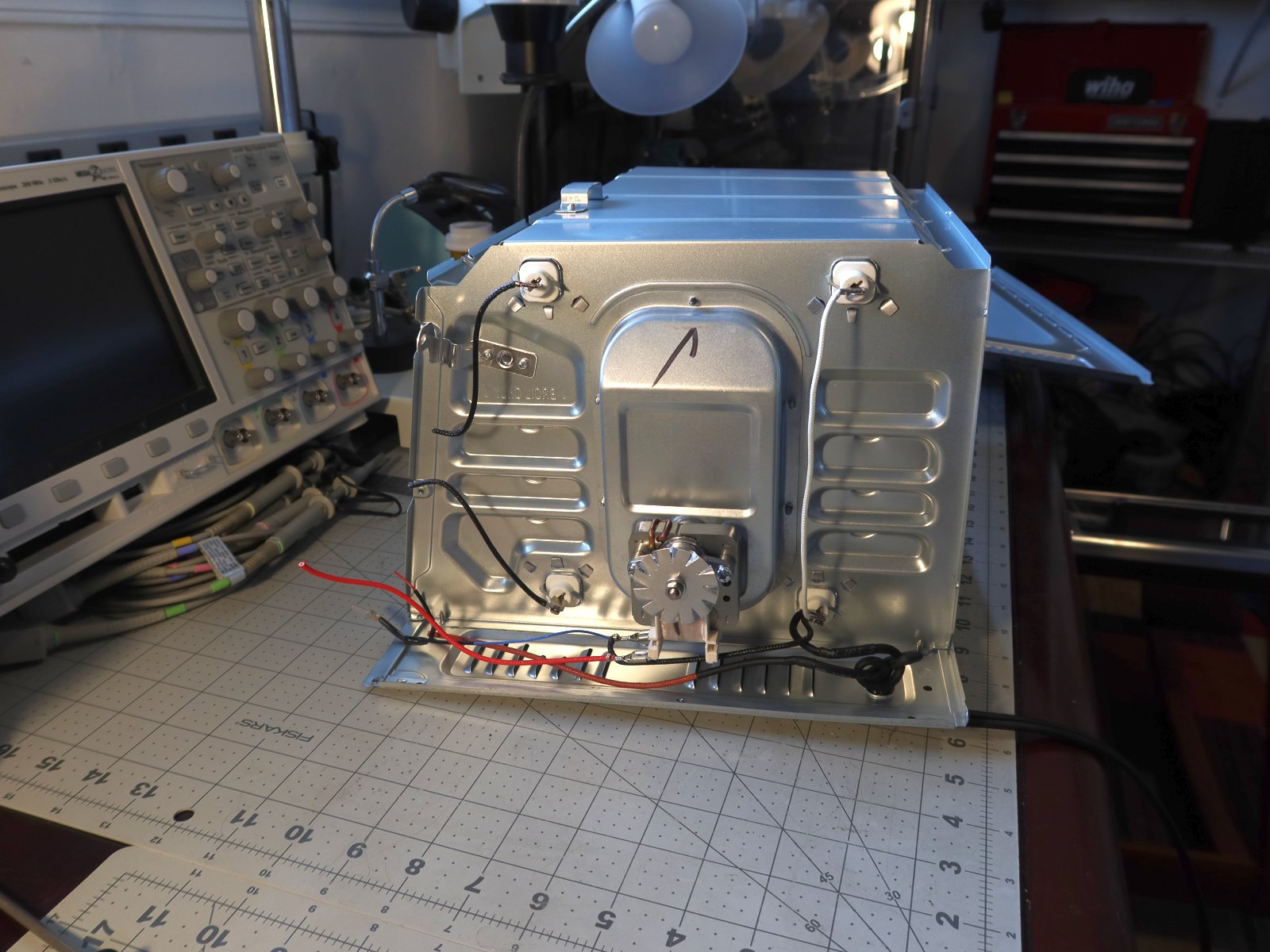

With the baseline measurements out of the way, I popped off the outer cover to see what was inside. The guts were entirely unremarkable, and looked like every other toaster oven that has been used for this.

Snip snip. Out went the stock controls and whatnot.

Unfortunately, the heating element connections were all spot-welded. The top elements were in series, as were the bottom elements. This was done with some (nichrome?) busbars on the left side. I wanted to completely disassemble the oven in order to be able to neatly apply the heat shielding / insulation to the interior, so out came the Dremel with a cut-off wheel. That quickly freed up the heating elements.

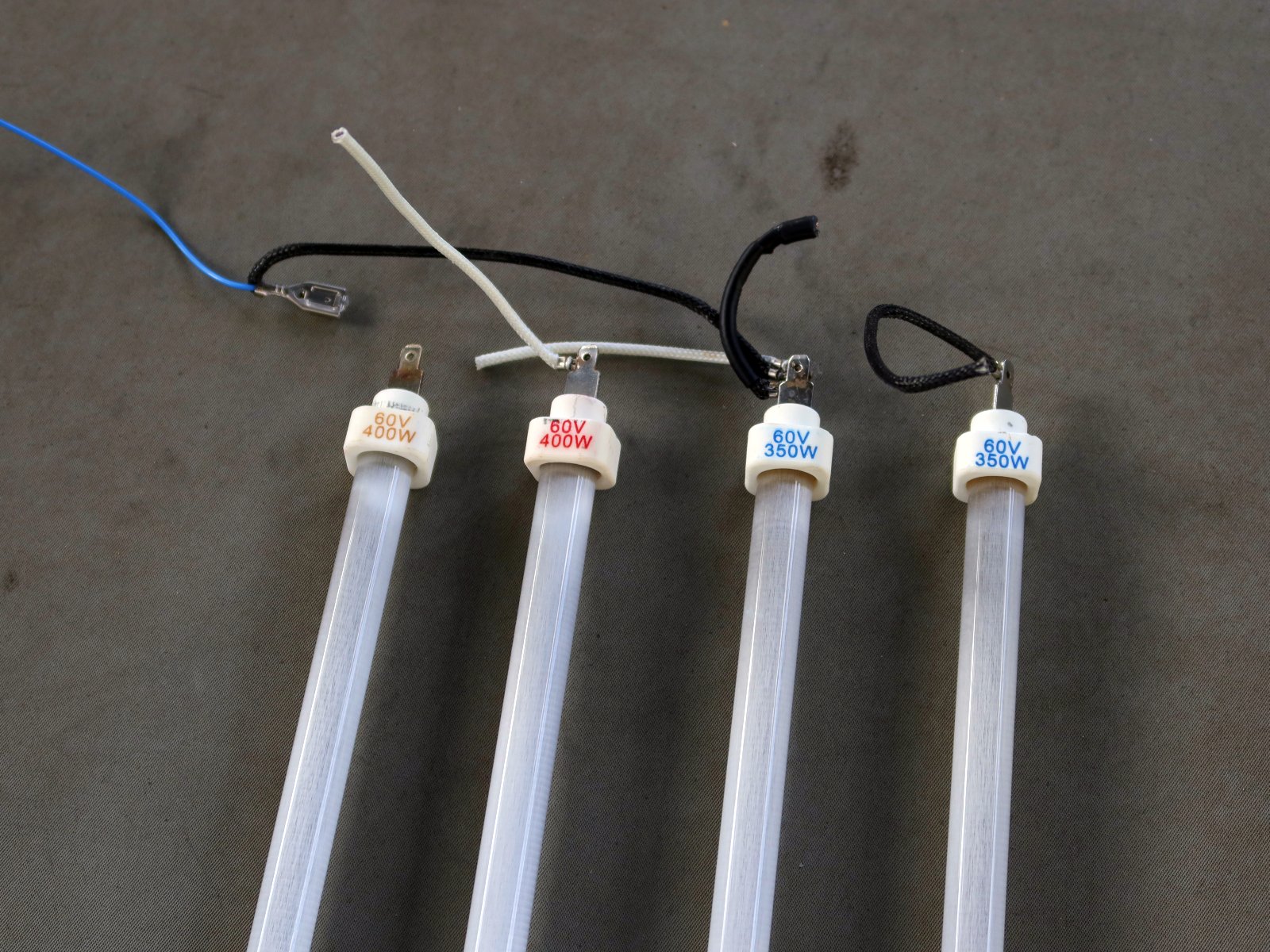

Interestingly, the top used two 400W heaters, and the bottom used two 350W heaters. I am glad that I pulled these out because I want the (slightly) higher power ones in the bottom.

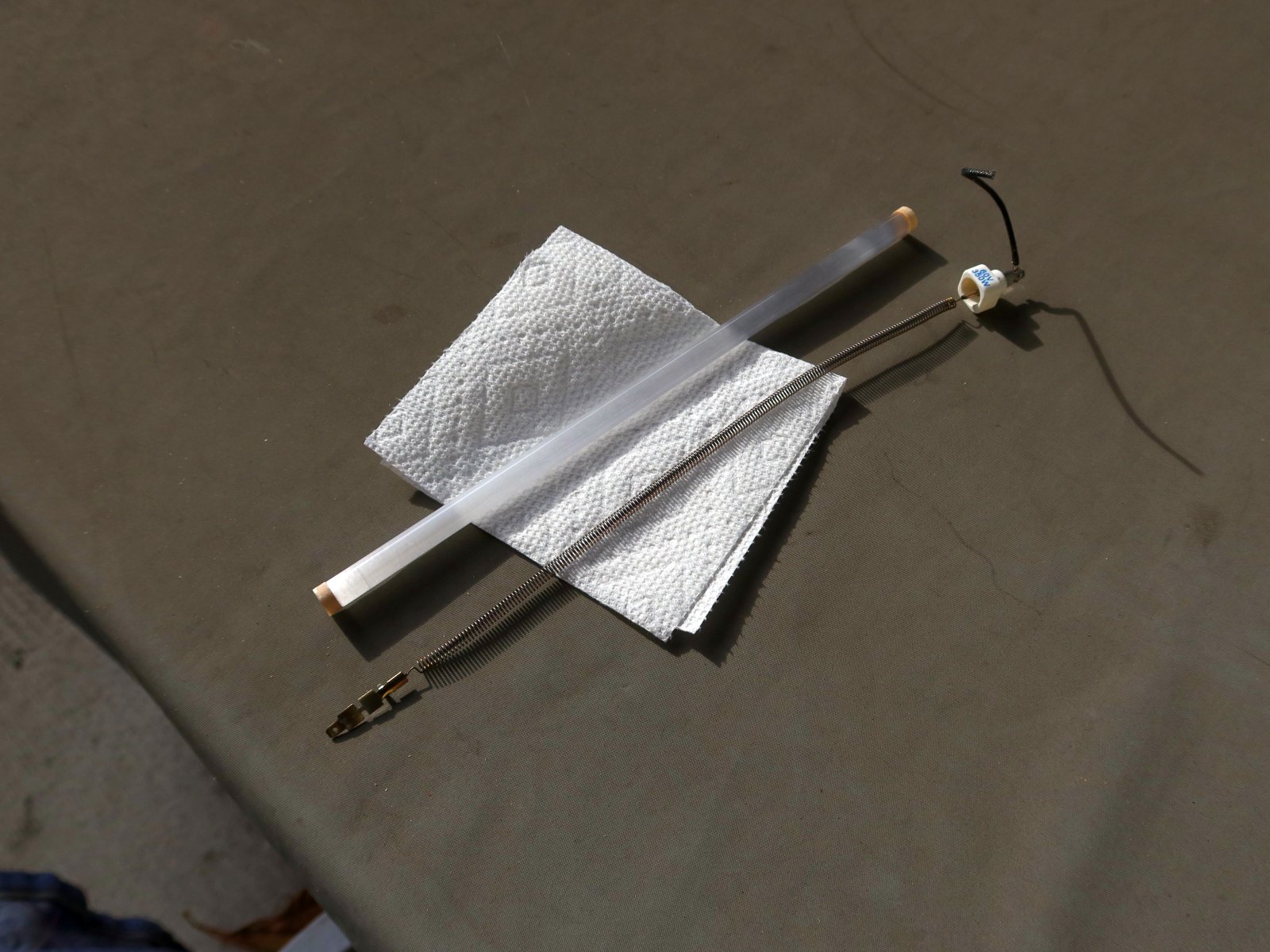

After grinding off the wire terminals on the opposite side, I carefully disassembled each heater so that I could blow out any dust from the grinding operations. The last thing I need is conductive crud in these things causing trouble.

So that is where I am at right now. The oven is completely taken apart, and I need to start ordering the heat shielding, insulation, MG wire, high temperature spade terminals, and of course the ramp/soak controller.

For heat shielding, I will be going with the Floor and Tunnel Shield II product that the Controleo3 kits use. Since I am using a different/larger oven, I will order it myself in the needed quantities. Similarly, I will be ordering the gold reflective tape recommended in the kit. The outside of the oven will get some fiberglass sheeting and a chopped-up welding blanket for additional insulation. The rear "pizza bulge" is going to be walled-off with a piece of metal sheet since it is just wasted space and more thermal mass to fight.

As far as the control method, I may go with a barebones Controleo3 kit (just the controller, basically). There are less expensive options out there, such as standard 1/16 DIN PID boxes, but the Controleo3 has plenty of spare outputs and seems to have had a lot of thought go into the firmware for this specific application. Having dual-zone heating control seems like it will really be beneficial since IR heating is really not the optimal way to do reflow and I will need to make the most of a sub-optimal architecture.

Questions for the good members of the forum:

- Should I keep the little perforated baffles which sit right above / below the heating elements? Presumably I want to minimize directly incident IR on the PCBs that I reflow.

- If the baffles should be kept, should I consider making new ones with no cut-outs?

- Would it be worthwhile to relocate the little convection fan into the bottom of the oven chamber? It really does not move much air, but it could help to mix things a bit. The original side location is basically useless.

- Any recommendations for controllers, if not Controleo3?

I will update this thread as I make progress on this! Comments and feedback are welcome.