I'm afraid I may not have explained my challenge accurately enough. I'm trying to drill reference holes in the plastic strips the non-camera S42 uses for PCB registration. Once I'm able to do so, I should be able to install a pair of reference pins in the strips, then fit PCB with corresponding holds over the pins, mill one side of a PCB, flip it, and mill the other, then drill and slip a bit of wire through, solder on both ends.

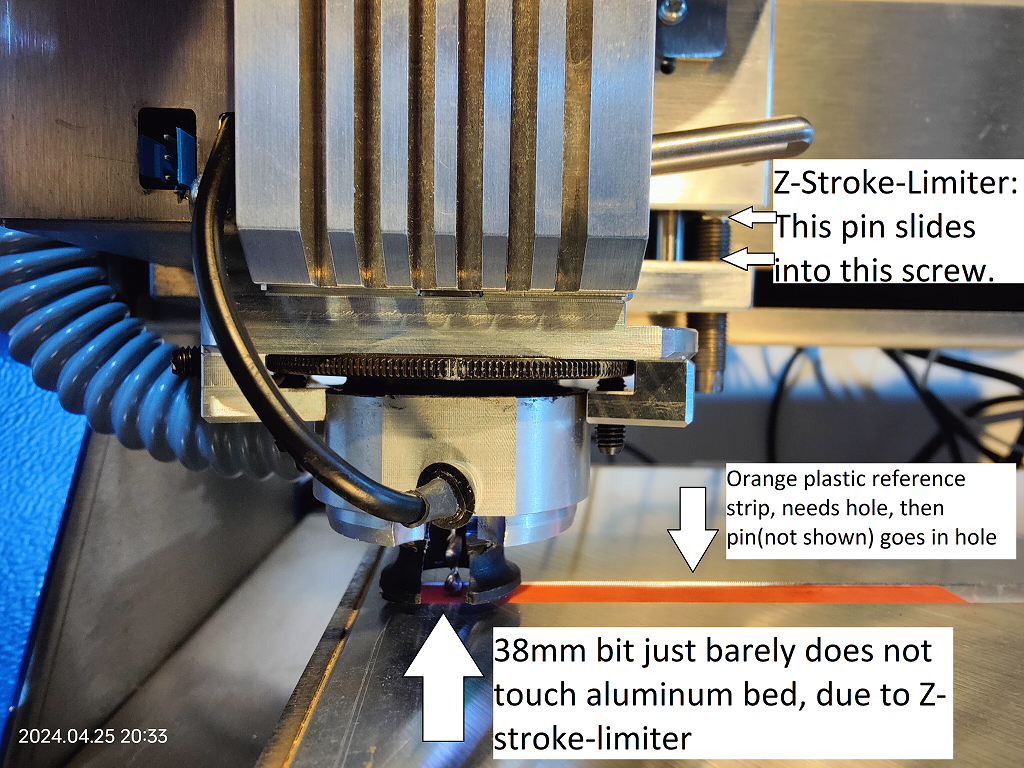

The bit for drilling the reference specified in the manual and software, as a 2.95mm drilling bit I couldn't find on LPKF's website. My machine came with two 38mm 2.95mm drill bits, but they're short enough that the Z-stroke-limiter just barely prevents contact with the bed or reference strips.

You've got me thinking that a longer 2.95mm drill bit is probably what the machine originally came with from LPKF, and I'd like to replace it, but I'd need to know the length required for the right depth. Too shallow and the pins are likely to loosen prematurely, too deep and it might drill fully through the reference strip into the aluminum bed.

I've attached a photo of my machine that I hope shows this better.