In case anyone else is concerned with EMI.

I'm installing 48x 8' 5500 lumen LED strips in the metal buirlding where I plan to build a screen room. On advice from a friend who was a TEMPEST engineer I bought CORCOM 6ESB1 & 20ESB6 filters with the intent of cascading them. I already had some 20VB1s

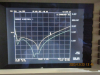

This shows the 6ESB1 and the 6ESB1-ESB6 pairing.

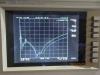

As I had them on hand I thought I'd see what benefit a 20VB1 might offer. The results were interesting as the order of filters made a significant difference at low frequencies.

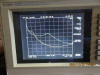

shows all 3 filters in different order with detail to 1 MHz

The ES filters have 330k ohm shunt resistors and the VB has a 1.5 M ohm shunt. After a series of experiments with a 4395A I found that the 6ESB1-20VB1-20ES6 gave the best attenuation.

These are my general shop lights in a 1530 sq ft building. It consists of 16 8' banks of lights each individually switchable. I'm buildnig an 11'x16' screen room in the shop, so keeping noise off the lines at the source is important.

All of the wiring is in EMT and will have hardware cloth screens over the lamps. The lab itself will be on an isolation transformer with lots of filtering.

Have Fun!

Reg