Finally, a SZA263!

I got it from a really dead FLuke 8842A.

Let´s see if I got everything right:

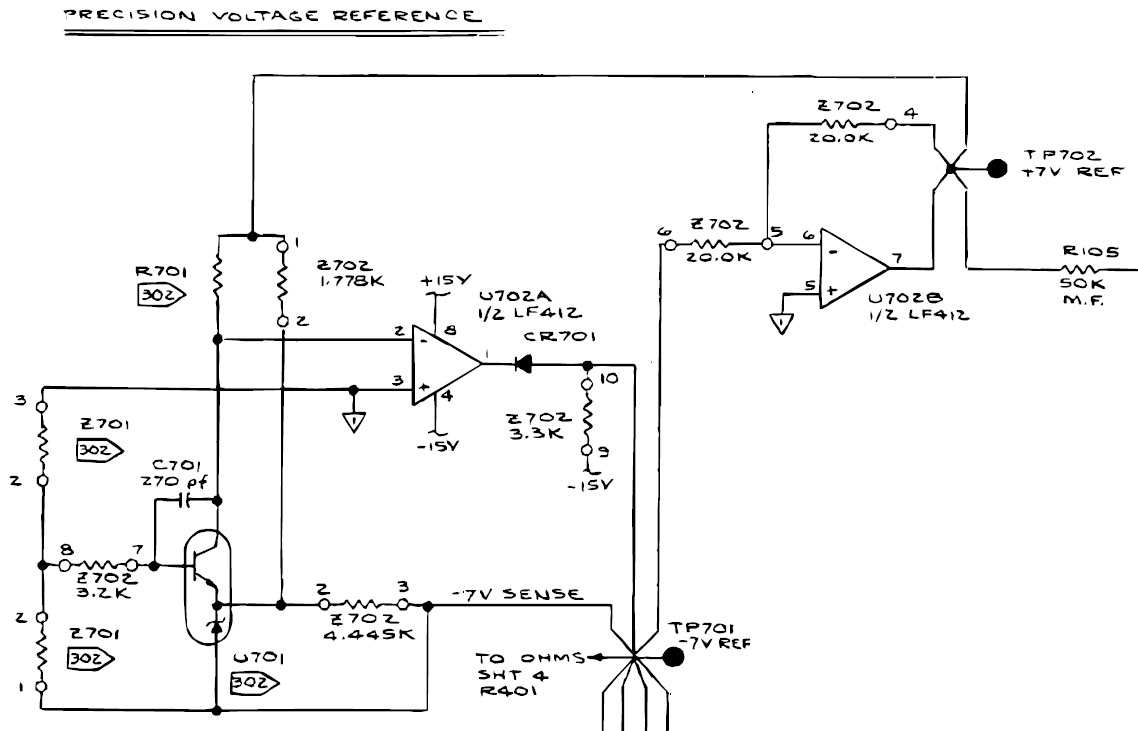

The servicemanual of the Fluke 8842A shows the structure of the SZA263 (U701). The base-emitter path of the transistor provides a negative temperature coefficient. The Z-diode offers a positive temperature coefficient. Suitably designed, there is a current at which the temperature coefficients balance out and the voltage between base and anode exhibits a vanishing temperature drift.

If the temperature drift of a Z-diode is compensated with a pn junction operated in "forward mode" this is just a temperature compensated Z-diode, as for example the 1N829A is (

https://www.richis-lab.de/REF22.htm). A ref-amp contains a transistor instead of a simple diode for temperature compensation. The transistor in addition drives the first control loop.

In steady state the opamp U702A ensures that a voltage of -7V is present at the testpoint TP701. In this state voltage divider Z701 sets a base current in SZA263 via base resistor Z702_8-7 that is exactly the current at which the Ref-Amp temperature coefficient becomes minimum. The basic reference voltage is applied between the base and anode of U702. Voltage divider Z701 scales this voltage to the desired output voltage of -7V. If the voltage deviates from -7V, more or less current flows through SZA263, which changes the voltage drop across resistor R701 via the collector of SZA263. The opamp U702A then readjusts the -7V reference voltage accordingly.

I´m not 100% sure with Z702_1-2 and Z702_2-3. Apparently they do some biasing. But they shouldn´t be necessary. Perhaps they compensate the fluctuation of the remaining temperature coefficient a little.

U702B ultimately generates a +7V reference voltage from the -7V reference voltage. Z702_9-10 is the bias resistor of the opamp U702A. Diode CR701 ensures that the voltage at testpoint TP701 does not become positive when the circuit starts up.

Resistor R701 defines the current flowing through the SZA263 and must be set to hit the point of minimum temperature coefficient. The voltage divider Z701 defines the reference voltage. The exact values of the resistors are correspondingly critical. R701 is a precision resistor from Dale. Z701 is a special balanced resistor network.

Accordingly, the Fluke 8842 servicemanual does not individually identify Ref-Amp U701, resistor R701, and resistor network Z701 in the part list. If one of these components is needed, one has to order a "REF AMP SET" which contains all three components and all of them have to be exchanged. The resistors are adapted to just the one SZ263 so that the temperature drift is minimal and the reference voltage is -7V or +7V.

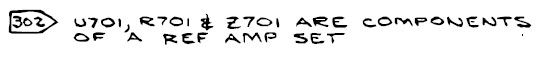

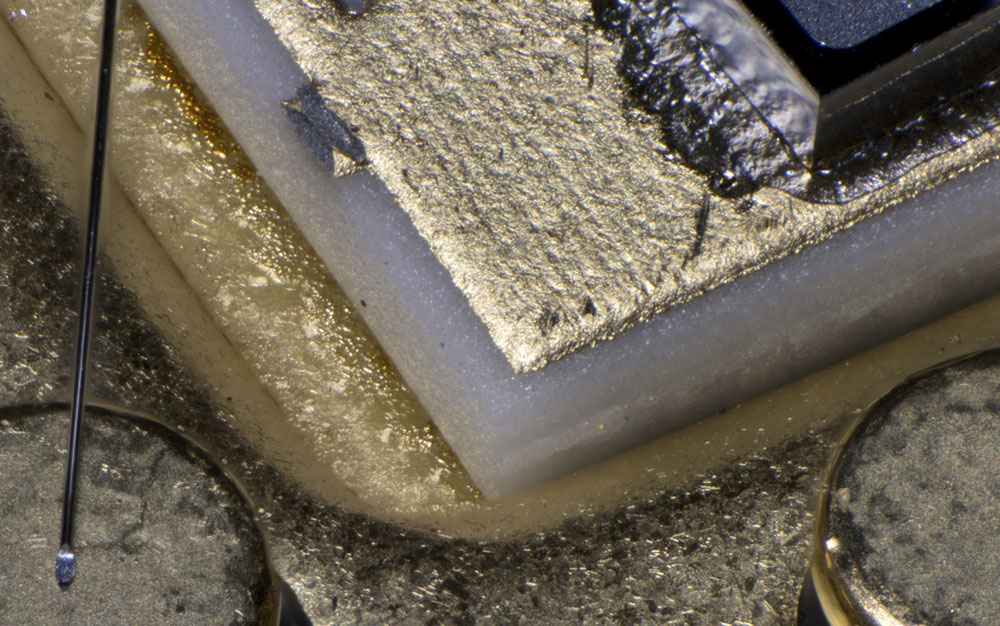

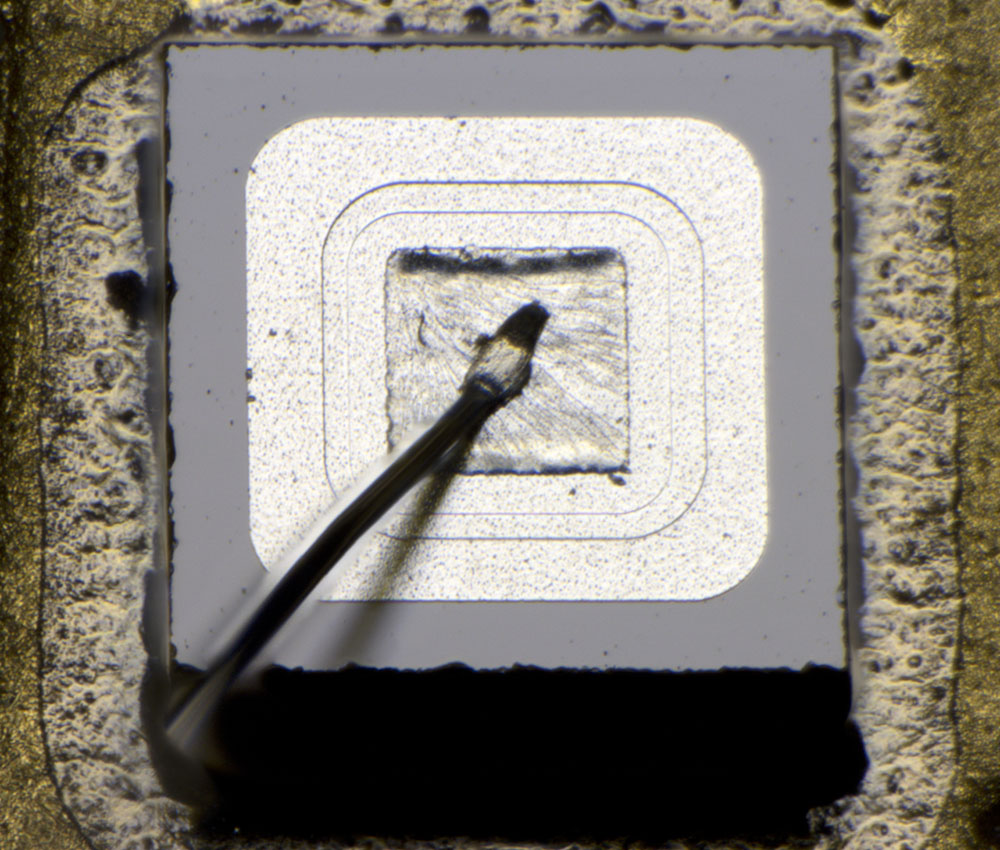

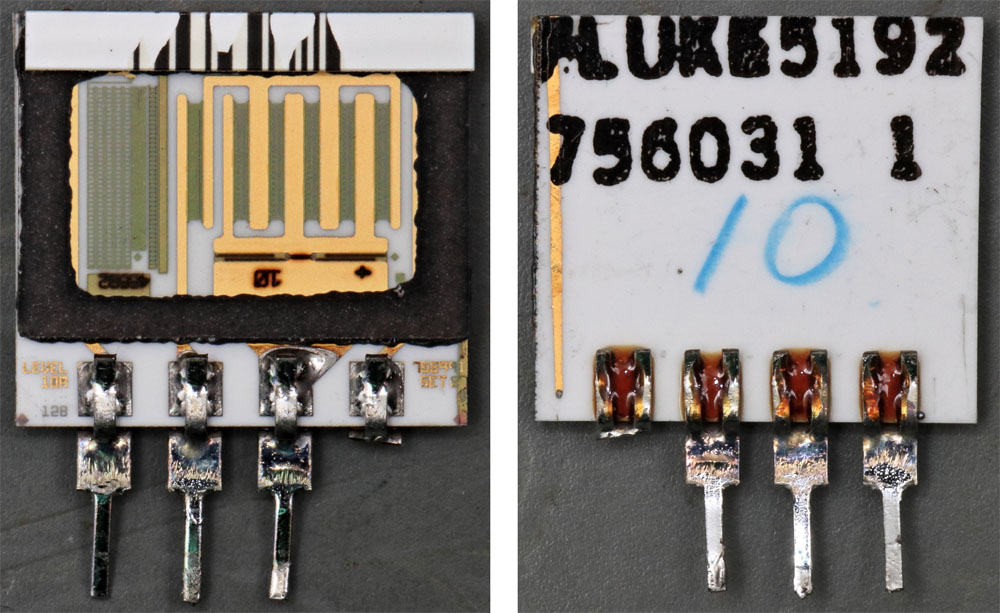

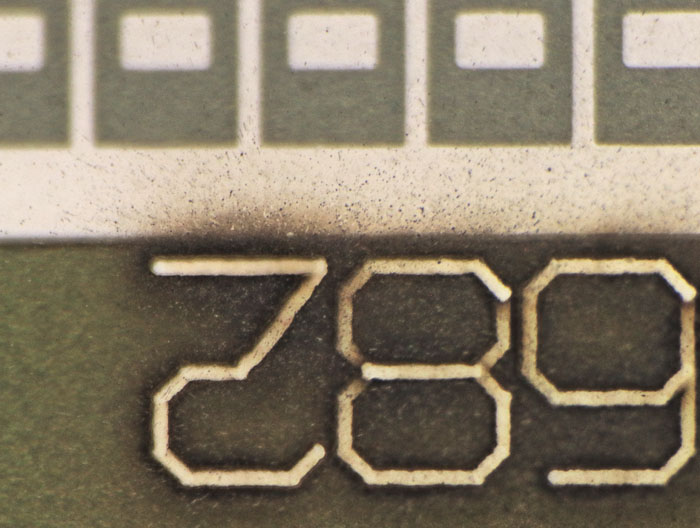

On the bottom of the SZA263 it can be seen that the case would have two more pins in addition to the four that are used. The additional pins have been shortened.

The additional pins are not contacted in the package.

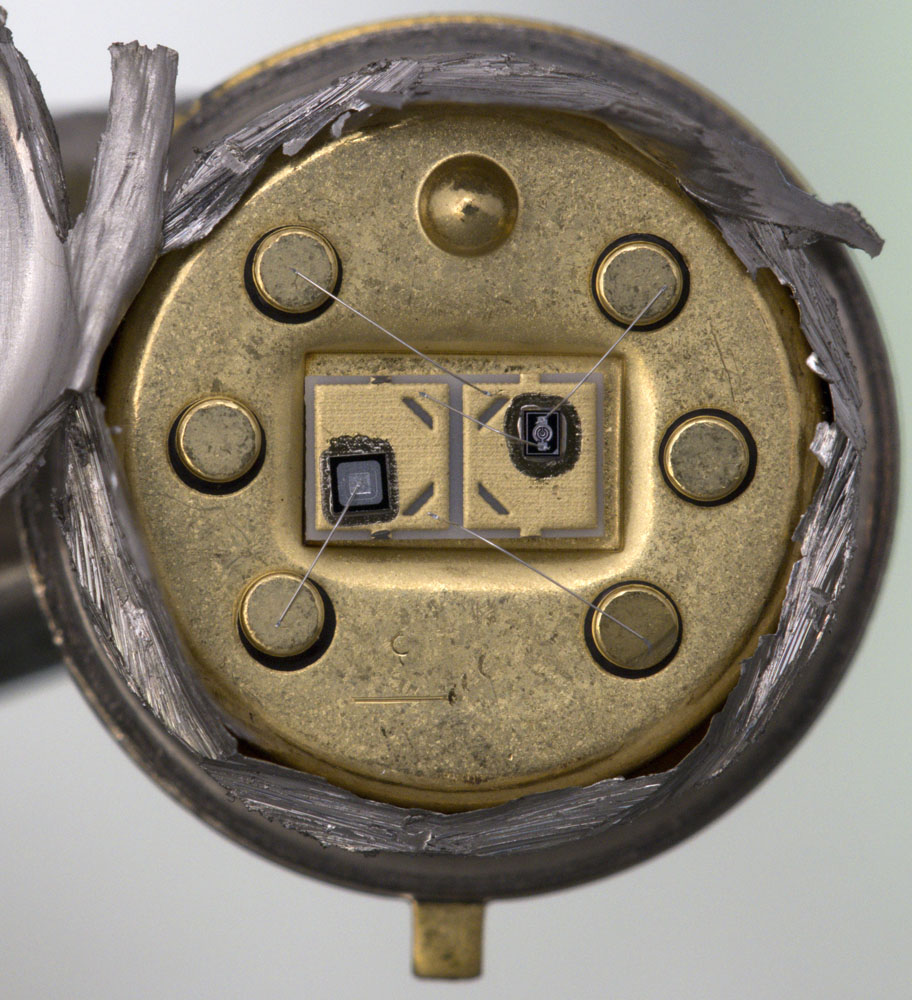

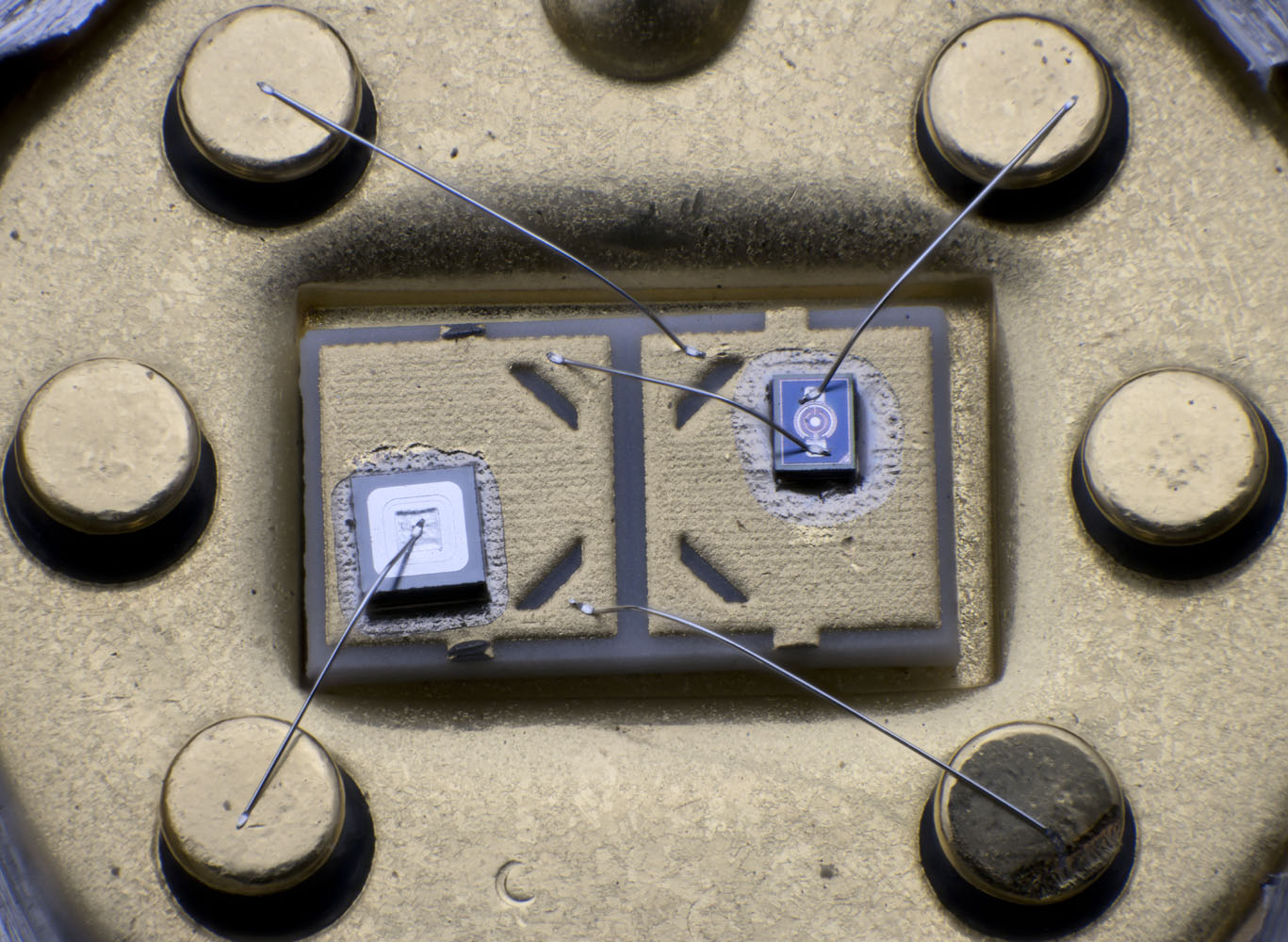

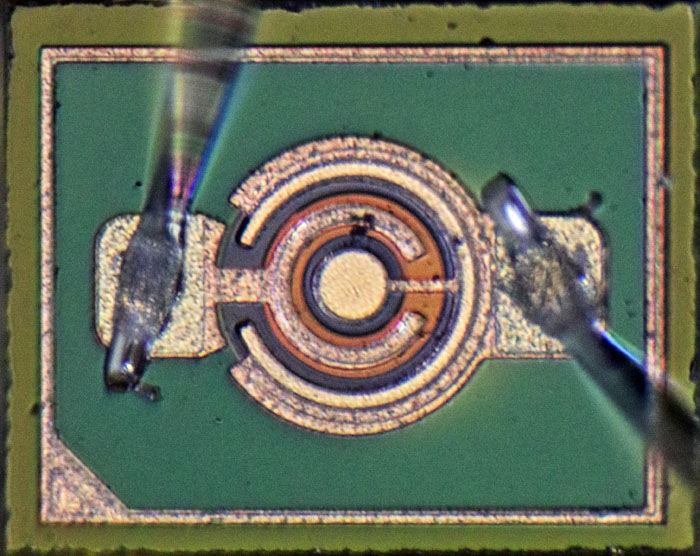

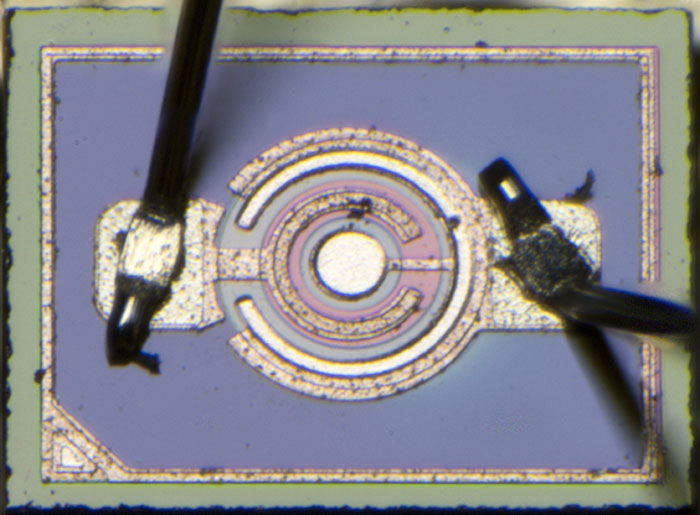

The Z-diode and the transistor are located on a ceramic substrate, which is fixed in a recess of the housing. The package itself is not connected to any of the potentials.

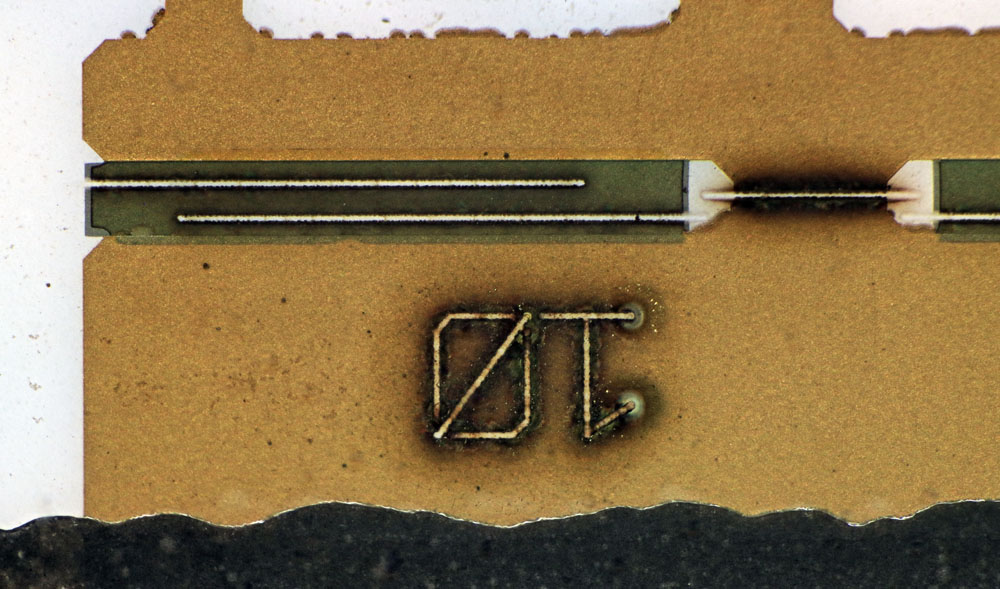

Two metal surfaces are applied to the ceramic substrate. The short lead residues leading to the edges indicate that a larger ceramic element was electroplated with the desired structures during production and then got separated.

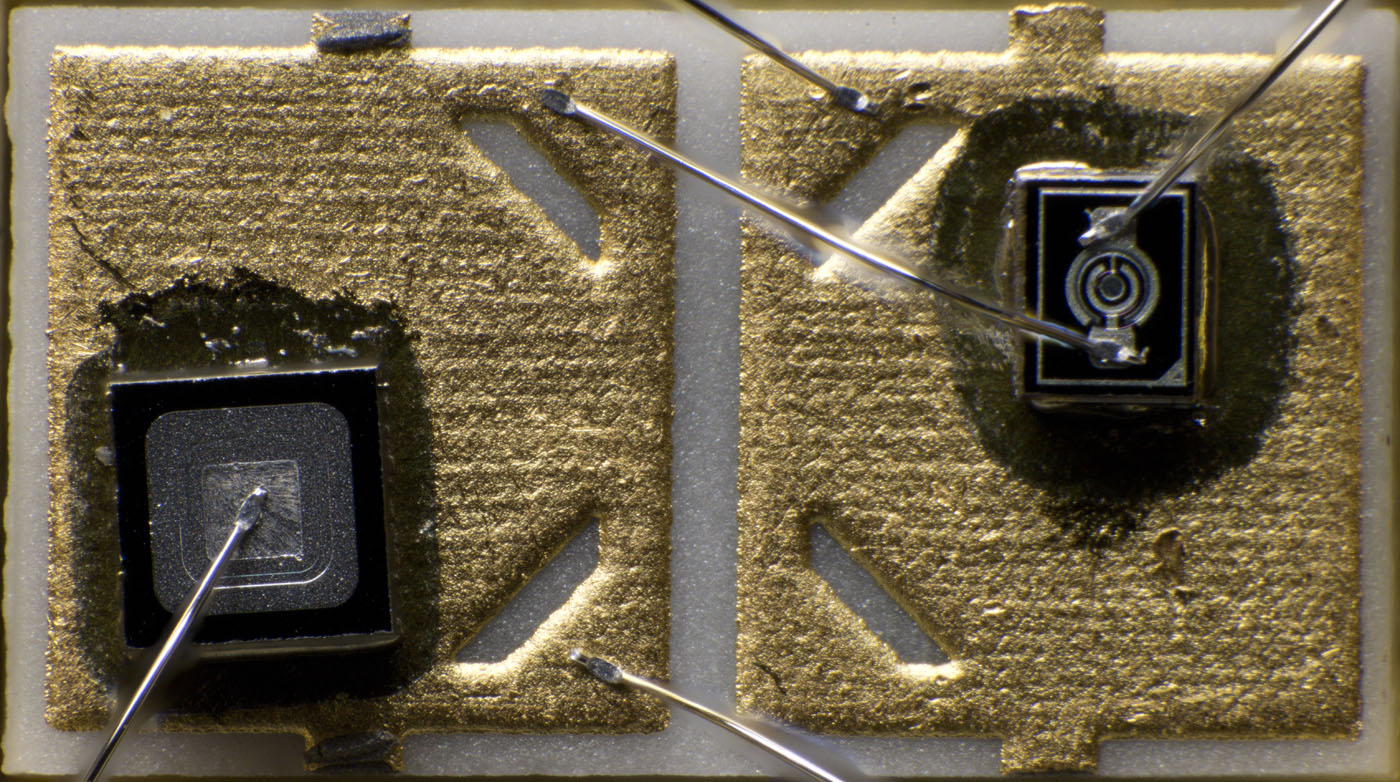

The edgelength of the diode is 0,59mm. The uneven surface in the center of the metal layer is reminiscent of the Z-diodes in the reference voltage source VRE305A (

https://www.richis-lab.de/REF21.htm#ZD) and in the digital-to-analog converter DAC80 (

https://www.richis-lab.de/DAC02.htm#ZD).

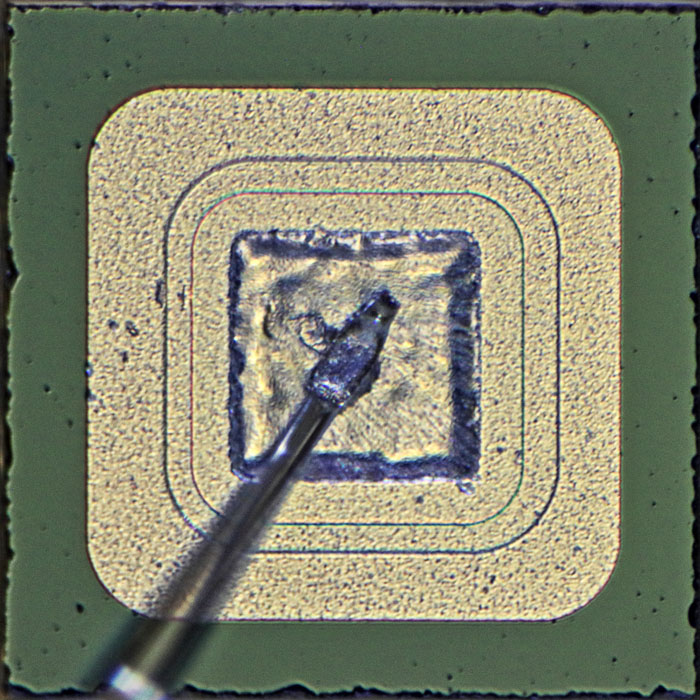

The dimensions of the transistor are 0,48mm x 0,38mm. The ring-shaped emitter is striking. The underlying base area is contacted inside and around the ring. The area of the base-emitter junction is a critical point when matching the temperature coefficient of the transistor to the temperature coefficient of the Z-diode.

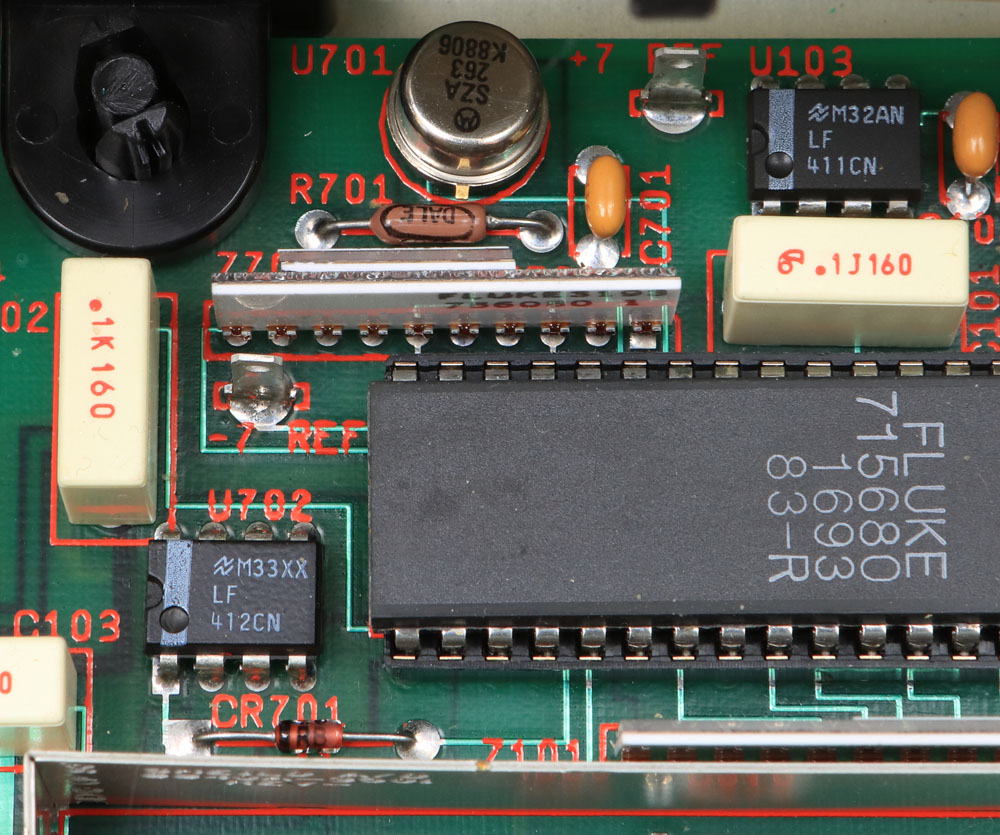

Here you can see the SZA263 in the Fluke 8842A bench multimeter. Below the SZA263 is the precision resistor R701 from Dale (411.62kΩ). Below that, the two resistor networks Z701 and Z702 are placed right next to each other. Most likely, the proximity was deliberately set up to keep the temperatures of the resistors as equal as possible. In the lower left area of the picture the operational amplifier U702 can be found.

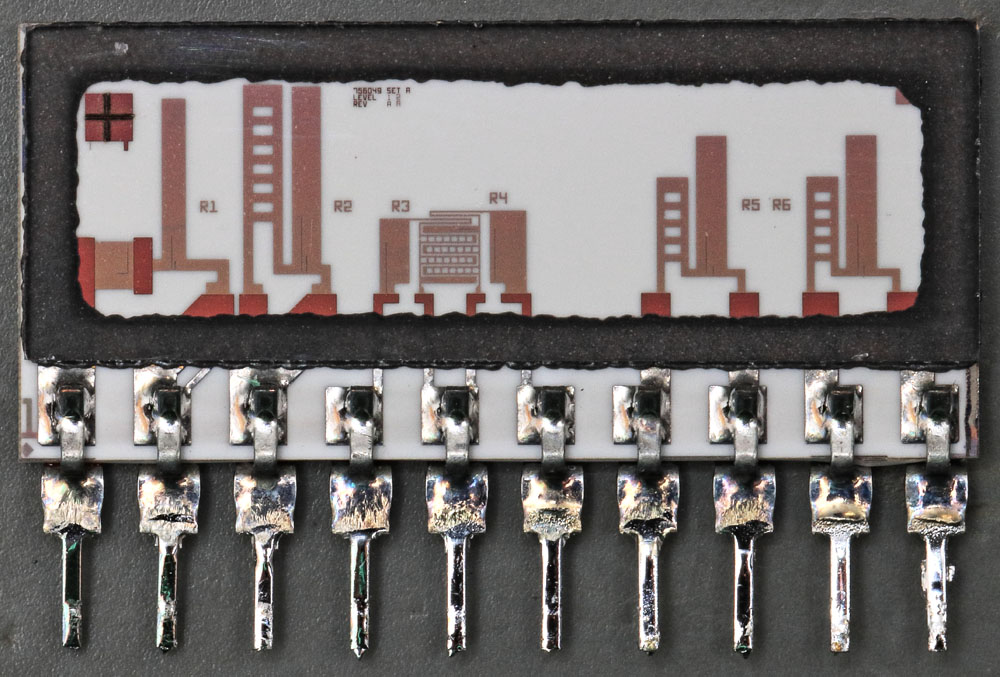

The resistor network Z701 that sets the ideal current through the SZA263 is listed as part number 756031. It is noticeable that the resistor network originally had four connection pins, one of which has been cut off.

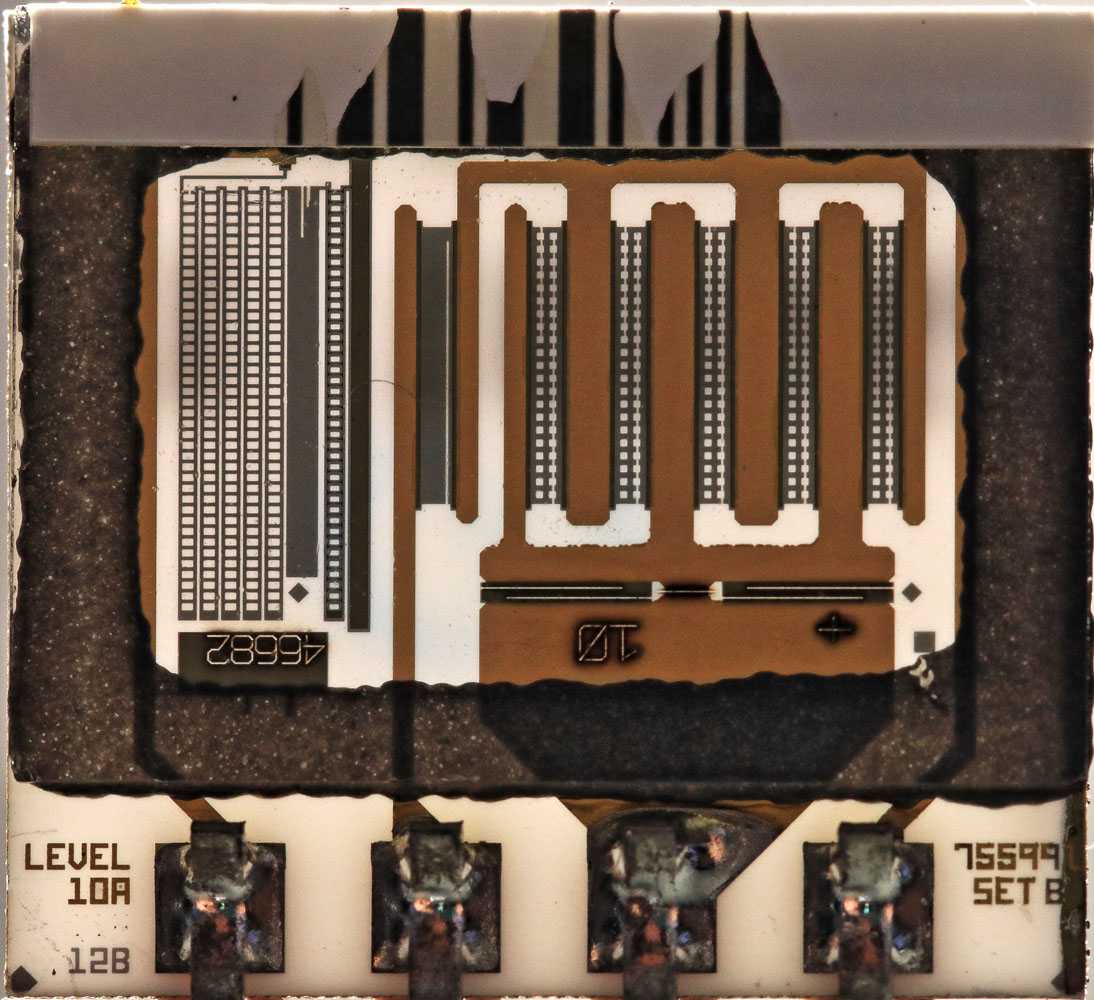

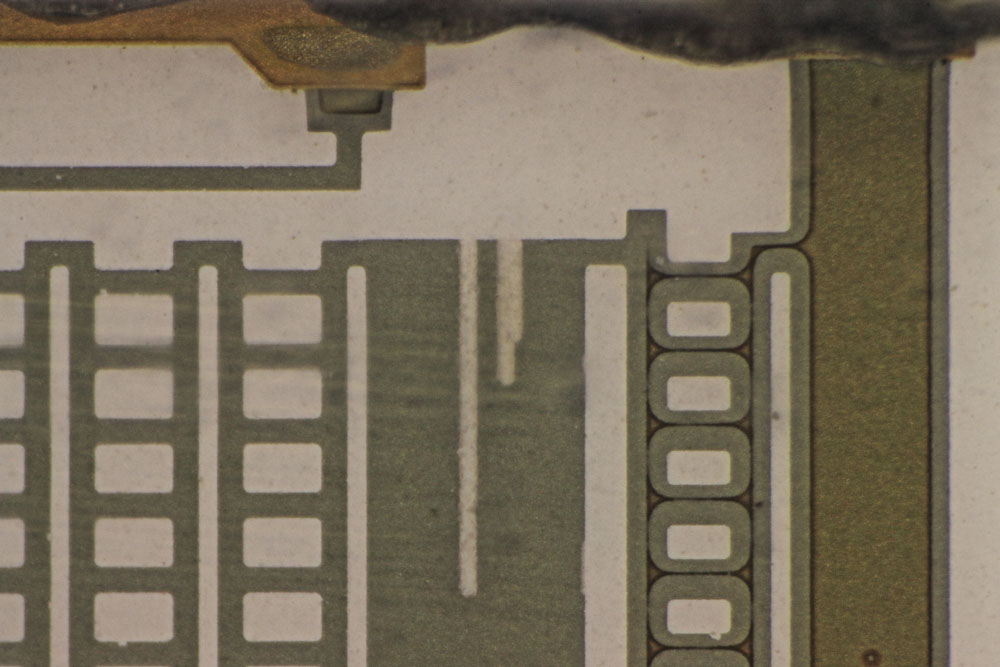

The resistors are placed on a ceramic substrate and are protected with a glass cover. The setup allows laser alignment at any time. For high-precision circuits, such a resistor network can be incorporated into an assembly and laser alignment can be performed as a final process on the completed circuit. In this way, it is also possible to compensate for disturbances that occur during a soldering or aging process.

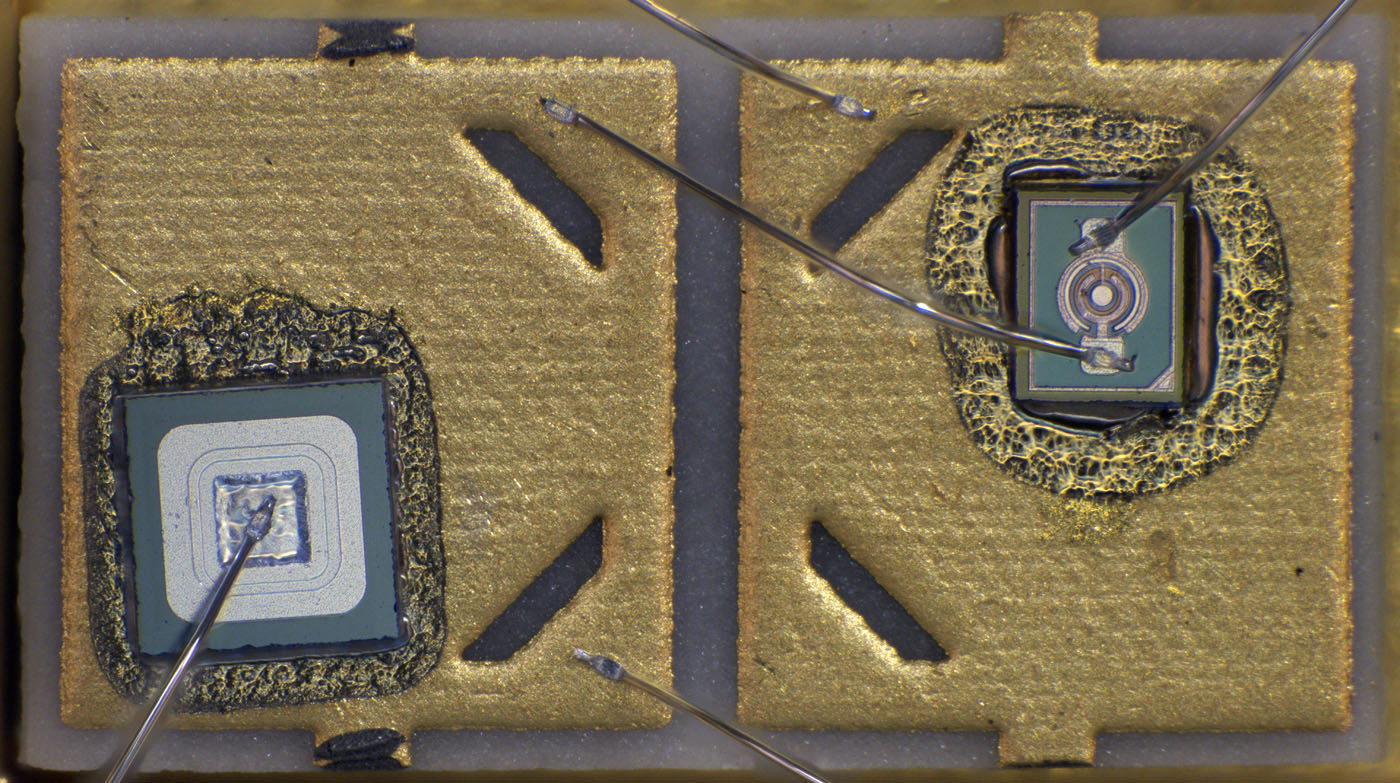

The leads on the ceramic carrier appear to have been gold plated. Each resistor consists of many different geometries, which make it easier to exactly set the desired resistance value.

A closer look reveals that it is not just two resistors. There is a third resistor on pin 2 that acts as an additional base resistor for the SZA263. Pin 4 allows to contact the common node of the three resistors, which makes the adjustment easier. The following resistor values can be determined (referring to the schematic above):

Voltage divider "1-2": 10,582kΩ

Voltage divider "2-3": 202,28Ω

Additional base resistor: 643,67Ω

At the bottom left of the ceramic substrate, three masks can be seen. Mask 10A defines the structures of the conductive paths. Mask 12B forms the resistors. The B suggests that this mask was reworked once. Between the masks 10A and 12B you can guess the characters 11A. It seems that this is the mask that defines the transition points between traces and resistors. Apparently, a special treatment of these areas was necessary.

The labeling on the lower right corner of the ceramic carrier shows that the original designation of the resistor network is not 756031 but 755991.

-reference-zener-diode-circuit/?action=dlattach;attach=136434;image)

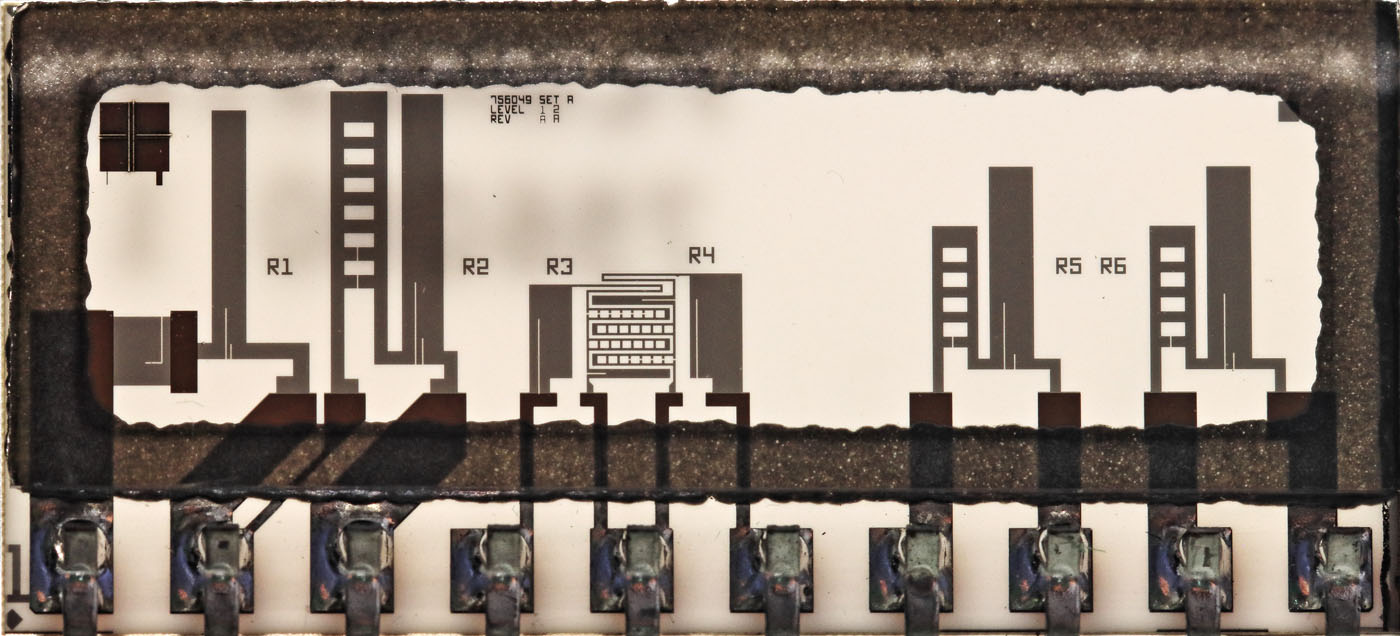

Here we have seen that in the 8842A (with SZA263) Fluke used also a different resistor network. This one actually has just three pins. No additional base resistor can be seen. Apparently, it was advantageous to make the base resistor adjustable in the Ref-Amp package. Maybe it was also possible to use another already existing resistor network.

At the upper contact you can see that the second mask is relevant for the contact areas between trace and resistor. In the right area you can see that a large part of the resistor material has been prepared to contact a trace. Probably the resistor network 755991 can represent two very different resistor values here. Once the right area is just contacted at the upper edge, another time an extended trace bridges the right two resistor strips.

Not only the resistor surfaces, but also the conductor paths were cut with a laser. The labeling most likely serves the traceability of the alignment process.

With the inscription in the left area, one can see that the adjustment was made after the ceramic carrier was sealed. The remains of the inscription process have settled on the glass.

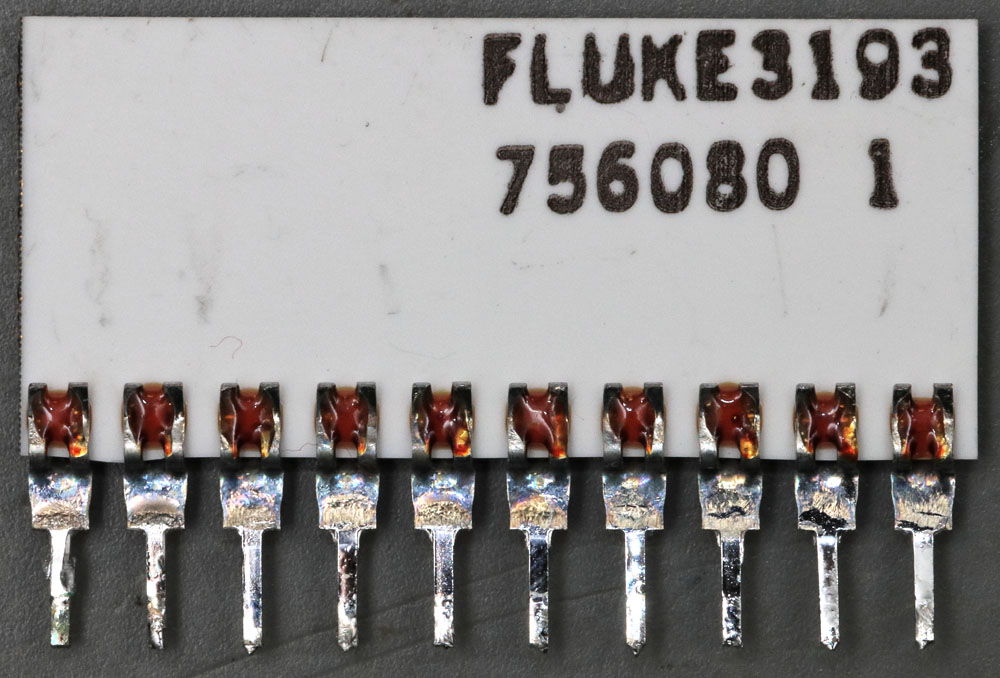

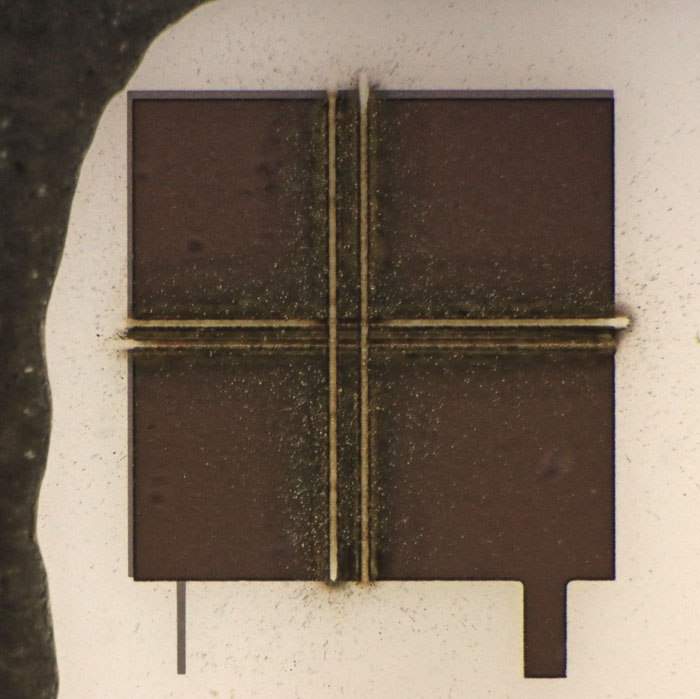

The second resistor network is called 756080. According to the optical appearance, the conductors are made of bare copper. In any case, it is not gold.

The individual resistors can be clearly seen. The resistance values are:

1-2: 1,7783kΩ

2-3: 4,4461kΩ

4-5: 20,005kΩ

5-6: 20,005kΩ

7-8: 3,2007kΩ

9-10: 3,3008kΩ

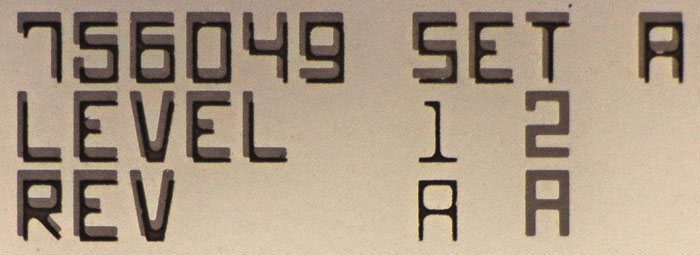

Here, too, a different number can be found on the ceramic carrier: 756049.

A mask for connecting the resistor surfaces with the conductor tracks cannot be seen.

Laser tuning alignment.

https://www.richis-lab.de/REF24.htm