@EmmanuelFaure

Hi, sorry to be slow replying - xmas stuff plus I was reading the article and thinking your post over. Thanks for the calculations and the link.

>>> The power required to maintain the temperature equilibrium, i.e. just to compensate the leaks, is : P=S.Lambda.Delta_T, which is roughly (0.05*0.05)*6*0.04*(50-20) = 0.018W. It's not that bad

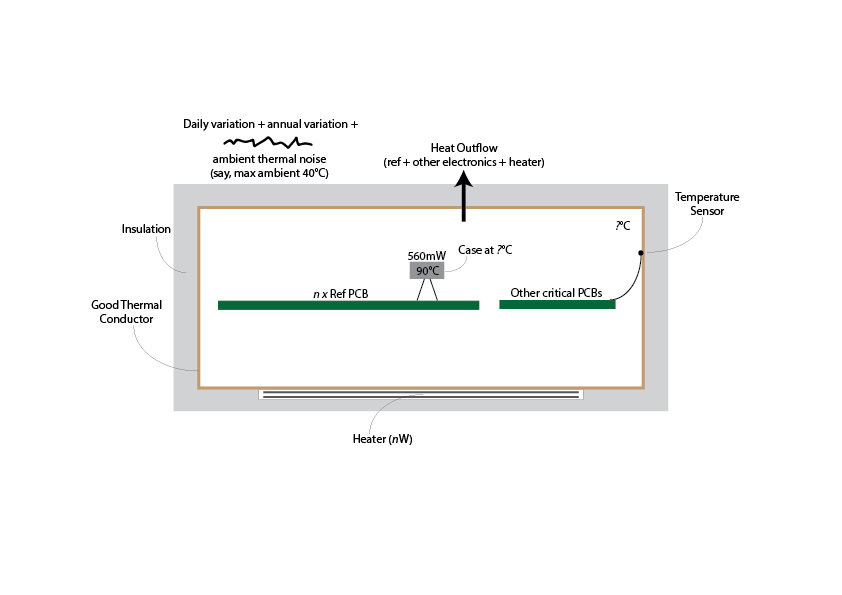

A single LTZ1000A board dissipates ~560mW (26mA heater + 5mA ref @ 18V) at ~22C ambient, so that suggests less insulation is needed. (The LTZ case is ~40C in this case with the die at ~90C).

The article is interesting - pity it doesn't have any pictures. One good thought is that the thermal control needs to be inside the thermally-controlled environment.

>>> With some clever design you can integrate the heating resistor + controller directly on the pcb, and you save a lot of assembly work & trouble.

Good point.

>>> Filtering daily temperature variations would be quite impractical because it would require an enormous mass/volume of thermal mass and insulation. The best way is the active/feedback control method.

Agreed, so the thermal capacity should filter out the ambient thermal noise and the active feedback the daily and annual slow variation.

>>> The key to successful thermal filtering is a good insulation AND a good thermal capacity.

So if some typical lab thermal noise was measured, that should let us calculate the required thermal capacity? This is similar-ish to a simple LP filter?

Is this the picture (below)?

I can't quite see the best way to get at the unknowns right now (target temperature for thermally controlled environment / heater power / etc). Is this a control theory problem or are there some rules-of-thumb?

Regards, Alan