Hi,

If you need a set of new/replacement rubber/silicone feet for your equipment, you can buy these in hardware stores and/or online. But if you have some spare RTV (or other type of mould making related silicone), you can make your own feet in various shapes and sizes. Reed on to know how.

Basically the hardest part of making you own feet is the mould to form the feet (apart of finding the silicone in reasonably small quantities of course

). One of the most easy to find and readily available options are medications/drugs blisters. Such blisters come in various sizes and somewhat different shapes. Say there are blisters with dome shape bottom/top (depending on how you look at it) or flat bottom, there are also blisters for capsules (i.e. oblong in shape).

Depending on your project requirements one can surely find suitable version of a blister. Here I'll show how I did my first set of feet using blister from round pills with dome shaped bottom.

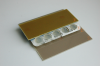

You will need several things:1. a flat rigid base surface (a piece of PCB in this case)

2. a double-sided self-adhesive tape

3. a medications blister

4. yet another piece of a flat rigid base surface (a piece of PCB yet again)

5. a set of weights (metal attachment plates for glass tables in this case)

And a silicone of course

Here are some pics to illustrate...

The end result...

Basic explanation of the process.

Basic explanation of the process.Take an empty medications blister (3) and using double-sided self-adhesive tape (2) attach it to a flat rigid base surface (1). Obviously blister is to be attached dome/flat surface facing the tape. Do not forget to remove any foil leftovers to interfere with the mould cavities. If you are using a two part silicone (as I did in my case; two part RTV platinum cure translucent silicone), mix a small amount (I've use two identical plastic bottle caps which was exactly enough for 10psc of 12x5mm feet) and pour it in the mould. Take another piece of flat rigid base surface and place (4) it on top of the blister (to squeeze out any excess silicone and ensure a flat attachment surface) then press it down with the weights. Leave the the whole thing to cure (it was 24h in my case, but the actual time would obviously depend on the silicone used). When cured, remove weights and the top plate, then remove the feet from the mould (if it hadn't done so already together with the top plate). Cut each feet out with exacto knife or nail scissors. Now you have your own feet, congrats!

Caveats (yes there are some).

Caveats (yes there are some).Blister mould cam be deformed from normal pill extraction, so it is best to use an unopened blister and remove the pills by cutting them out. Silicone (the version I've used) is prone to air bubble formation, hence these bubble can damage the end product (silicone can be degassed, but this requires appropriate equipment). Some types of silicone are difficult to attach since it doesn't stick to anything (this is exactly the trouble I have).

Other considerations.There are many types of silicone, so many options are available (including hardness, colour, resistance to chemicals, etc.) to experiment with. There are great many of different pill out where with different blister sizes to suite many different needs. I've used Sh13 (Shore A) hardness silicone which is far to soft, but that's all I had available, Sh30 - Sh40 (Shore A) would probably be more appropriate.

Hope it's of any use to anybody...