The LT1012 is a precision operational amplifier which is advertised in the datasheet as a better alternative to the OP07 (

https://www.richis-lab.de/DAC07.htm#OP-07). Accordingly, the maximum offset voltage is 25µV with a maximum temperature drift of 0,6µV/°C. The bias current remains below 100pA. Between 0.1Hz and 10Hz, the noise voltage is a maximum of 0.5µVpp. A supply of +/-1.2V is sufficient for the LT1012. The current consumption is 500µA maximum. The cutoff frequency for this is just over 500kHz with a slew rate of 0.2V/µs maximum. With a feedforward compensation up to 10V/µs can be achieved.

To understand how the LT1012 works it is worth taking a closer look at the patent US4575685. Behind it are the almost legendary names Robert C. Dobkin, George Erdi and Carl T. Nelson.

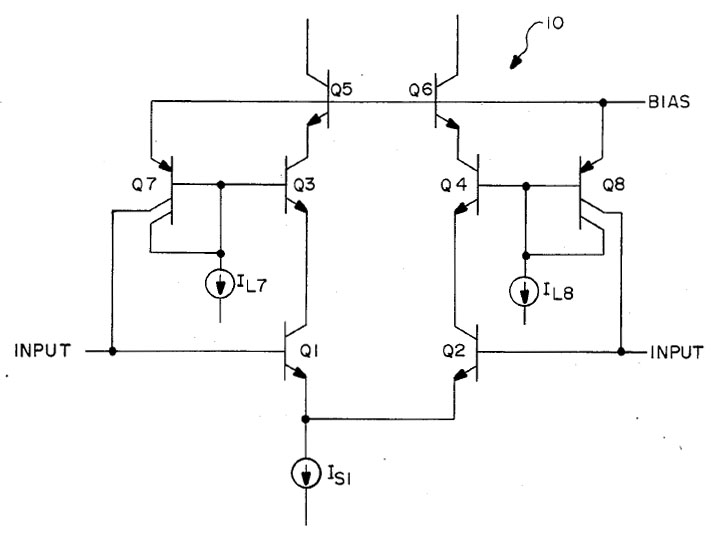

With the above picture the patent represents the state of the art to reduce the bias current of an operational amplifier. The collector lines of the input transistors Q1/Q2 contain the transistors Q3/Q4. If the transistors have the same structure, the base current of Q3/Q4 corresponds to the base current of Q1/Q2. Transistors Q7/Q8 mirror this current to the inputs where it compensates for the bias current.

In practice, however, leakage currents occur, indicated here by the current sinks IL7/IL8. As a result current flows away from the base of Q7 and Q8 which negatively affects the compensation current. The typical lateral PNP transistors have a large contact area between the base region and the substrate or the insulation surfaces. Relevant leakage currents occur there especially at high temperatures. Another disadvantage of the above circuit is that it is influenced by the common mode voltage at the inputs. Nevertheless it is quite sufficient for many operational amplifiers. However, if you want to work with very small input currents, you have to improve the bias compensation.

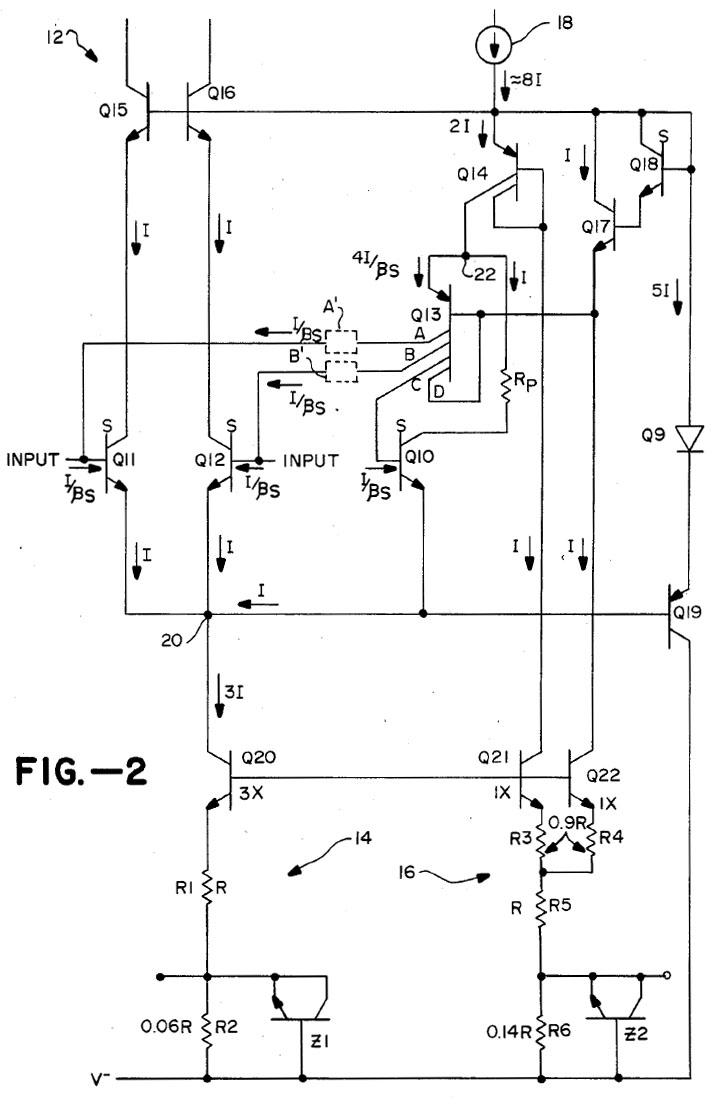

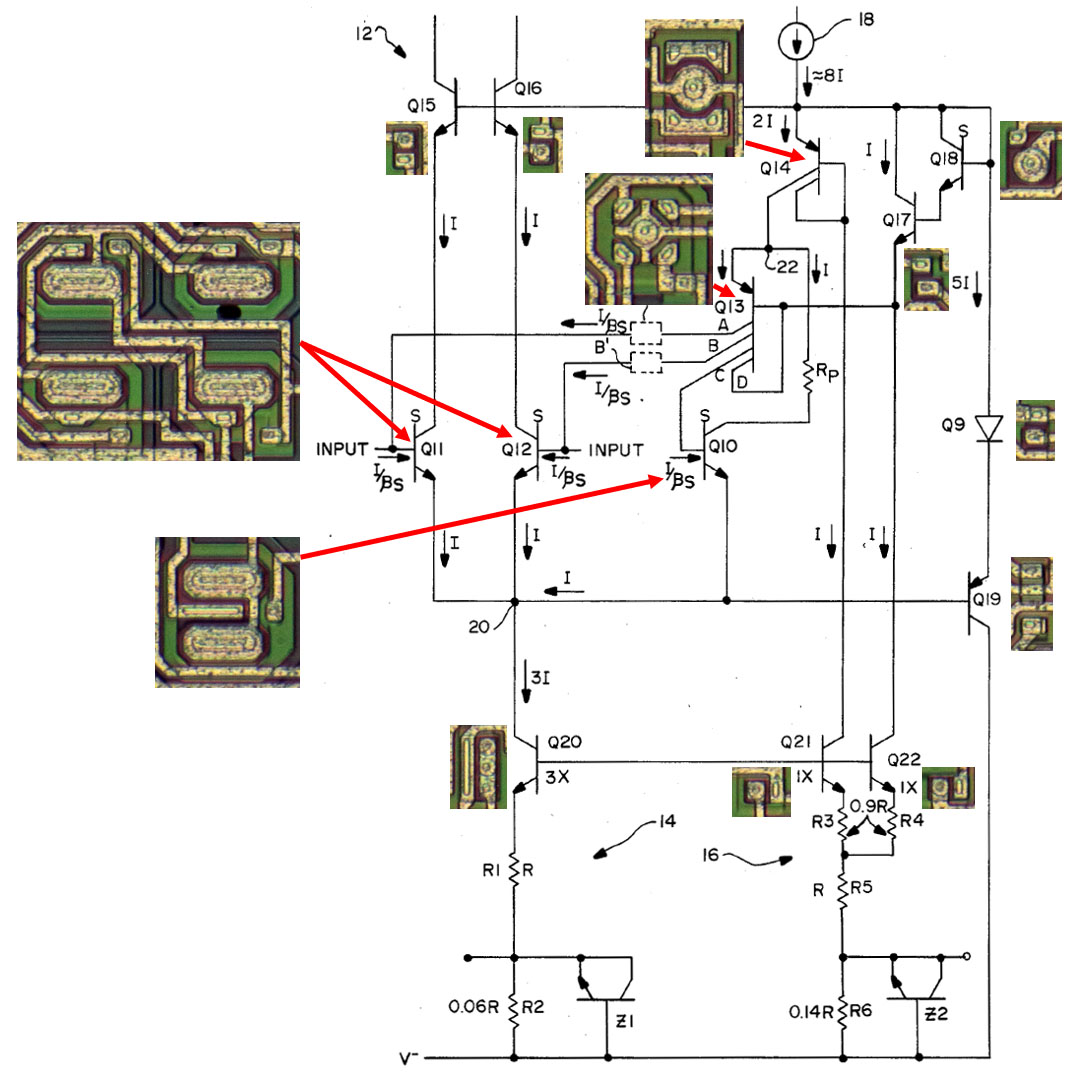

Patent US4575685 deals with a circuit that compensates the bias currents more precisely, but is also considerably more complex. The transistors marked with an S are so-called "super-beta transistors". These transistors offer a very high gain factor in the range between 1.000 and 10.000. In addition, they can be manufactured with very similar electrical characteristics, which is particularly helpful here.

The additional current sink Q21 determines with the current mirror Q14 that the same current I flows in direction Q13/Q10 as to each of the input transistors Q11/Q12. The interconnection of Q13/Q10/Rp ensures that a base current is established at Q10 so that current I can flow out via Rp. Q13 does not form a current mirror in the classical sense. Q14 drives current through the emitter of Q13 until enough current flows through its collector C to drive Q10 to the point where current I flows through its collector. The base current of the super-beta transistor is so small that it can be neglected.

Q13 now transfers currents to the inputs via its collectors A and B which correspond to the base current of Q10. Since Q10 has the same structure as the input transistors Q11/Q12 and also conducts current I, the base currents of all three transistors are equal and the currents of Q13 can compensate for the bias currents at the inputs. The collector D is not needed and is just present so that the transistor can be constructed symmetrically. As a lateral PNP transistor Q13 suffers from the same leakage currents as the PNP transistor of the first circuit but here they are fed by Q17 and thus do not affect the compensation of the bias currents.

The patent specifically notes the importance of current mirror Q14. If the voltage at the inputs reduces faster than 0,1V/us the capacitance at the base of Q10 would be sufficient for Q10 to take most of the current from Q20. The operating point of Q11/Q12 would shift due to the lack of current and the transfer characteristics would deteriorate. The capacitance at the base is typically no more than 20fF. However, the base current discharging this capacitor is also just 0,5nA to 2nA due to the super beta transistor. Since Q14 limits the current through Q10 to the value I Q10 not only is prevented from taking current from the input transistors Q11/Q12. Q10 thereby saturates which increases the base current and quickly discharges the parasitic capacitance there. This ensures that when the voltage at the inputs changes rapidly the bias current does not fluctuate.

In order for transistors Q11/Q12/Q10 to behave as equally as possible their collector-base voltages should be equal. It is also advantageous if the voltage is small and independent of the common mode voltage at the input. The collector-base voltage of Q11 is determined by the base-emitter voltages of Q19/Q9/Q15/Q11. According to the patent the different current values and transistors provide a collector-base voltage in the range of 0.1-0.2V.

The collector-base voltage of Q10 is defined by the path Q15/Q16/Q18/Q17/Q13/Rp. The same voltages are present at Q10 and Q11 if the base-emitter voltage of Q13 has the same value as the sum of the base-emitter voltage of Q18 and the voltage drop across Rp. Although these are very different elements, the patent states that this requirement is satisfied relatively well even at different temperatures.

The surrounding current sources and sinks must, of course, be constructed so that the necessary currents are established. Below the differential amplifier these are not 2I but 3I due to the additional transistor Q10. According to the patent the same current does not necessarily have to flow in the right-hand branches Q21/Q22 as in the input transistors, but the currents must be constantly proportional to each other. The ratio, which also affects the base currents, can then be corrected via the resistors A' and B'.

The Z-diodes Z1 and Z2 represent fuses that can be triggered in production and make it possible to adjust the current ratio of Q20 to Q21/Q22 accordingly. Thus the strength of the bias current compensation can be adjusted.

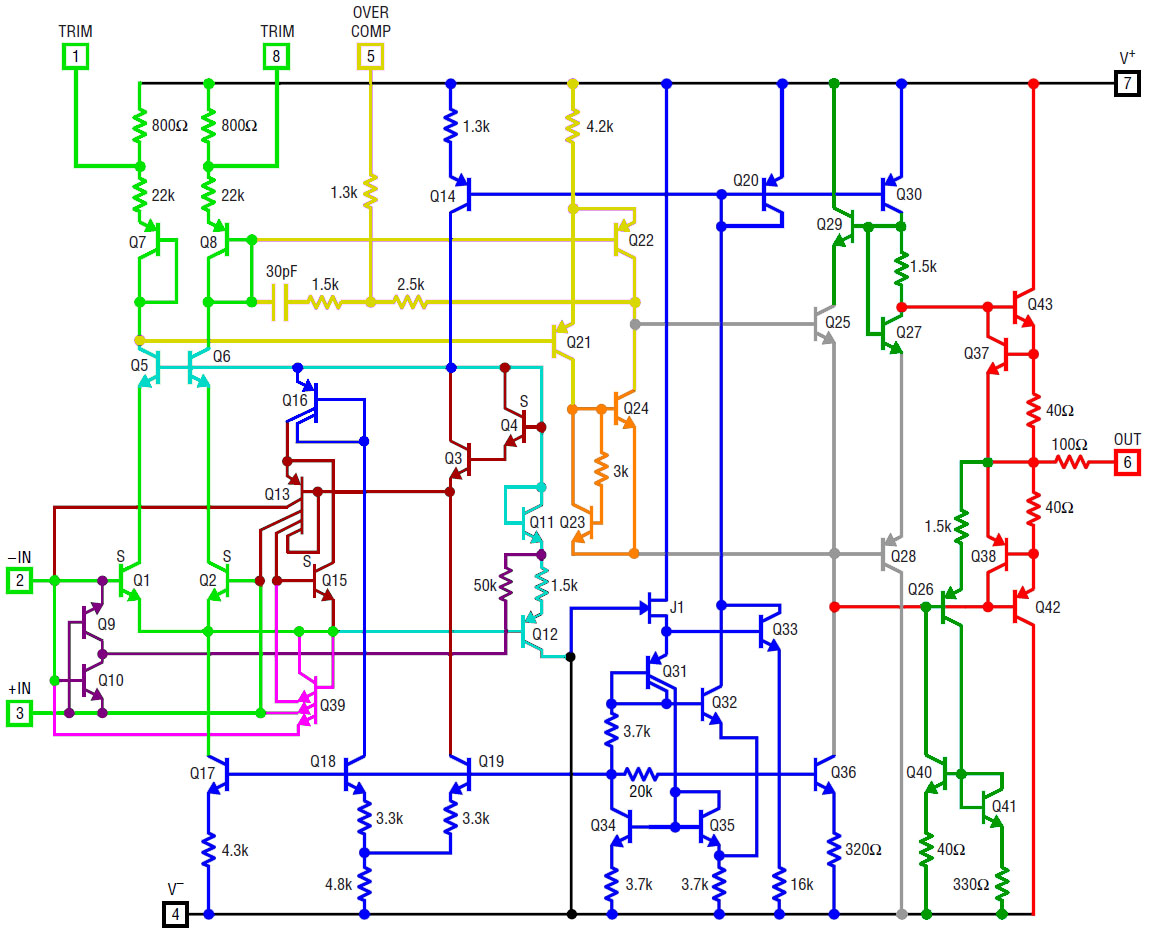

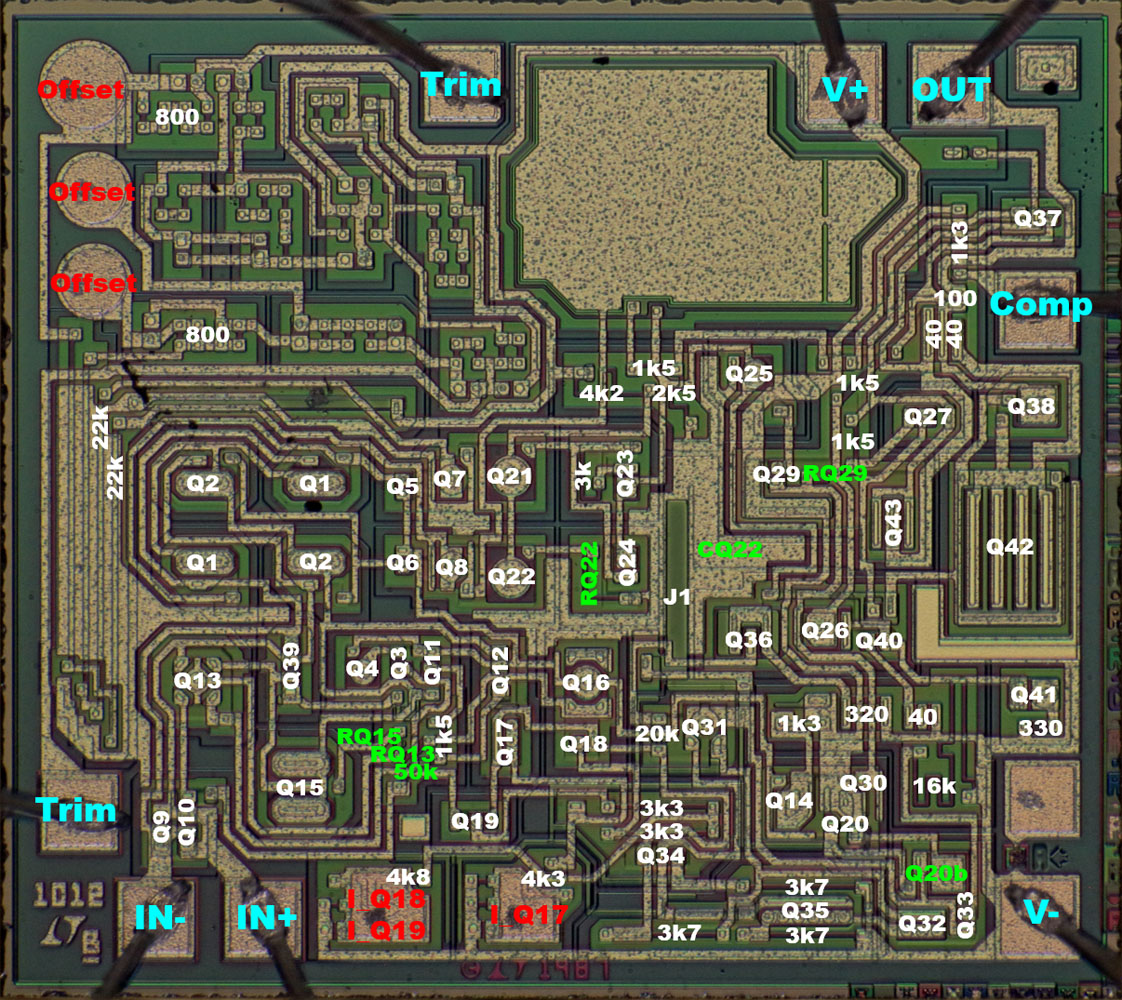

The datasheet contains a circuit diagram, which is much easier to understand with the above background information. As usual the biasing of the different circuit parts is done by a series of current mirrors (blue). The generation of the reference current is surprisingly complex.

The input transistors in the differential amplifier (light green) are super beta transistors. The very high current gain factor is of course extremely advantageous for the input transistors. At the collector resistors the trim pins are connected, which allow an adjustment of the offset from outside the package.

The cyan circuit, as described in the patent above, ensures that the collector-base voltage of the input transistors Q1/Q2 remains constant. The dark red circuit part maps the compensation of the bias current, also described in the above patent.

In addition to the bias current compensation, the differential amplifier features Q9/Q10 (purple) and Q39 (pink). Q9 and Q10 serve as clamping diodes, limiting the input voltage between -IN and +IN. The purpose of the connection to the cyan circuit remains unclear. Current can flow across this connection only if an input potential becomes lower than the emitter potential of the input transistors.

Q29 gives you three diodes, which apparently should accelerate the clearing of the free charge carriers in the super beta transistors. What is otherwise more relevant for power transistors could also be helpful here due to the high gain factors.

The voltage amplifier (yellow) is based on transistor Q22. Via pin 5 the frequency compensation can be extended externally. Q24/Q24 (orange) generate the voltage drop, which provides some quiescent current in the output stage. Q21 is driven inventoried to Q22 and can take over its current, which makes the highside of the output stage activate faster.

Q25 and Q28 represent the drivers of the power stage (gray). If the voltage amplifier stage supplies more current Q25 conducts more current and the level of Q28 decreases. This means that Q42, the lowside transistor of the output stage, is driven less. At the same time, more current flows from Q30 into the highside transistor of the power amplifier stage (Q43) and drives it harder.

If the voltage amplifier stage reduces the current, the excitation of Q25 decreases, more current flows out of Q42, and the output of the opamp swings toward the negative supply potential. At the same time Q28 conducts more current and reduces the excitation of the highside transistor.

The complementary output stage (red) is equipped with an overcurrent protection circuit (Q37/Q38). The 100Ω resistor at the output improves the behavior with capacitive loads.

Between driver and output stage there are further protection circuits (dark green). Q26 becomes conductive when the output has a high potential and the lowside transistor of the output stage is driven strongly. As a consequence, Q41 and Q40 become conductive, which reduces the output level. This ensures that transistor Q42 is not loaded beyond its SOA range.

Q27 reacts similarly. The output potential is applied to its emitter via Q28 and Q42. If this potential is very low and a high current flows across the 1,5kΩ resistor at the same time, Q27 sinks the base current of the highside transistor. Q29 simultaneously reduces the current flow through Q25, which means that the hihgside transistor is driven even less hard.

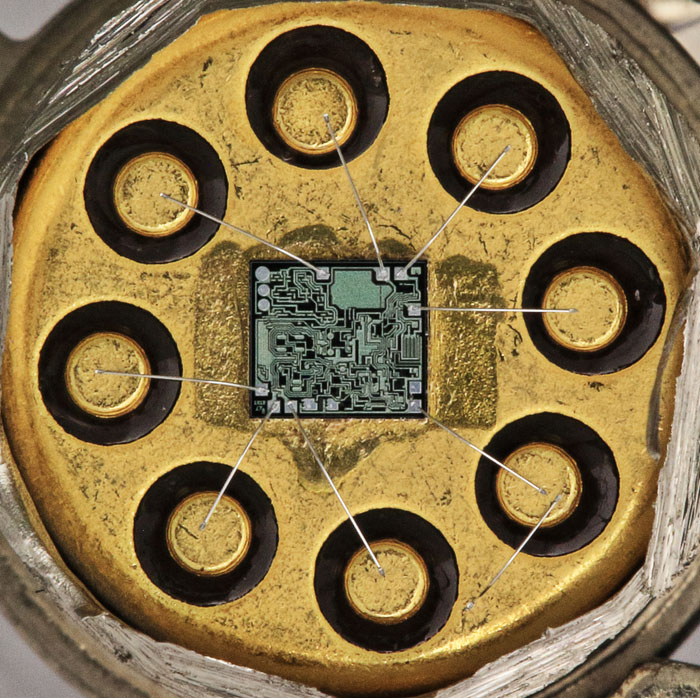

One bondwire connects the pin of the negative supply to the housing.

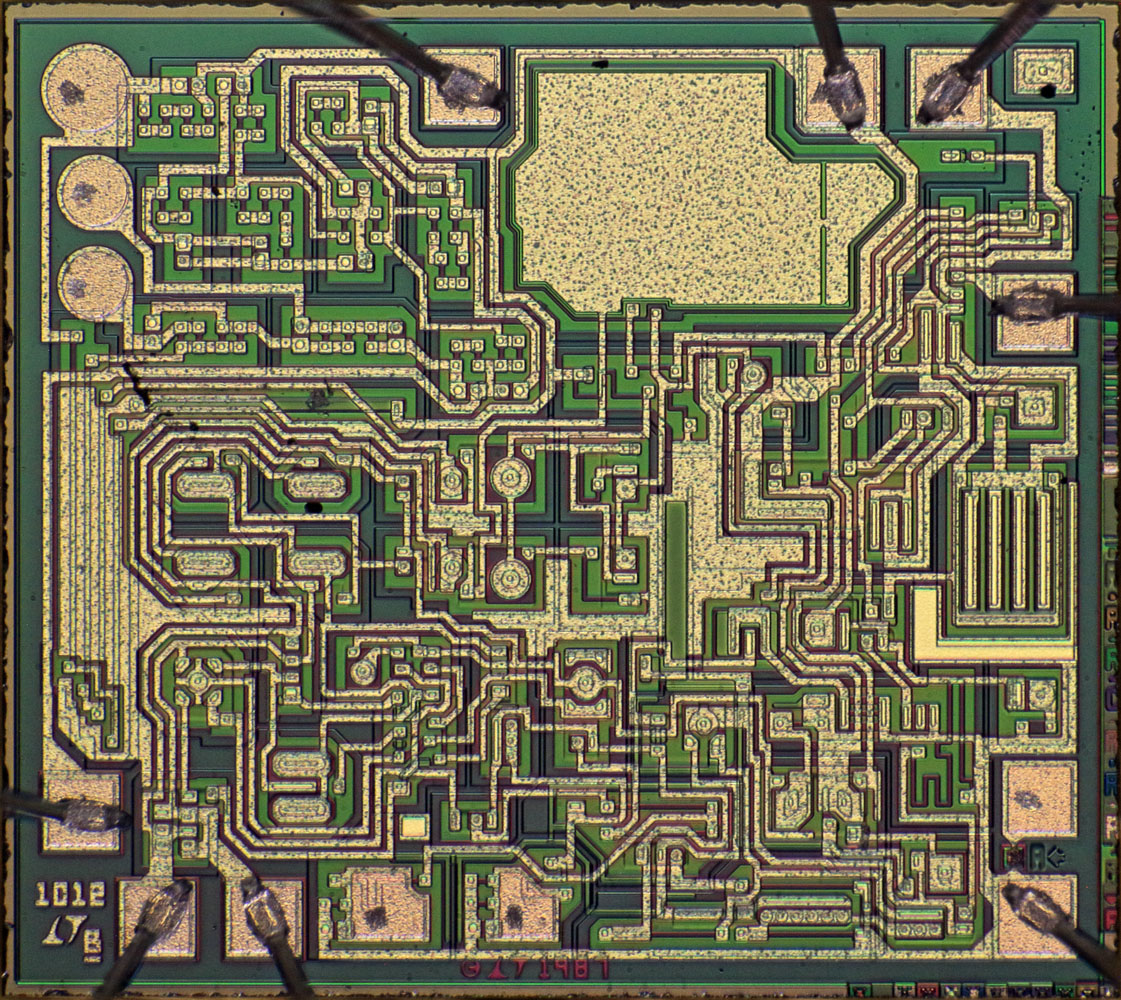

The Die ist 1,8mm x 1,6mm.

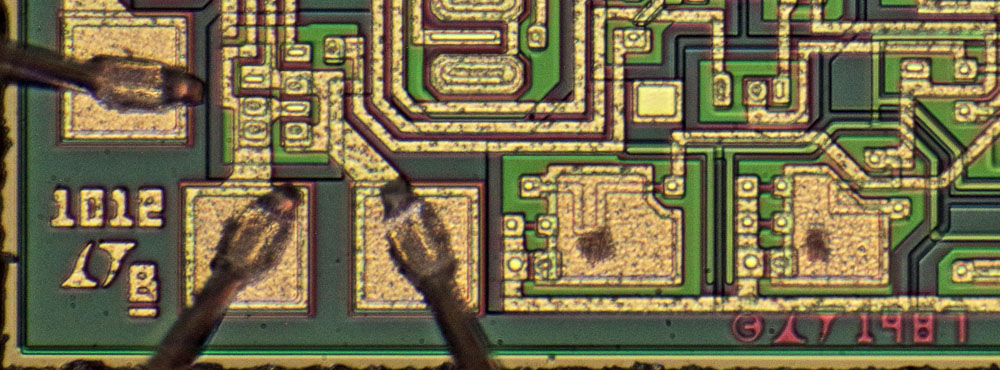

The design dates from 1987. The B could indicate a second revision.

The milling path contains the revisions of nine masks and some patterns that allow to check the alignment of the masks against each other.

The circuit includes several Zener fuses. A metal fuse is integrated between the negative supply potential and a testpad which does not interfere with the circuit. Presumably it was triggered during alignment, perhaps to indicate the quality level.

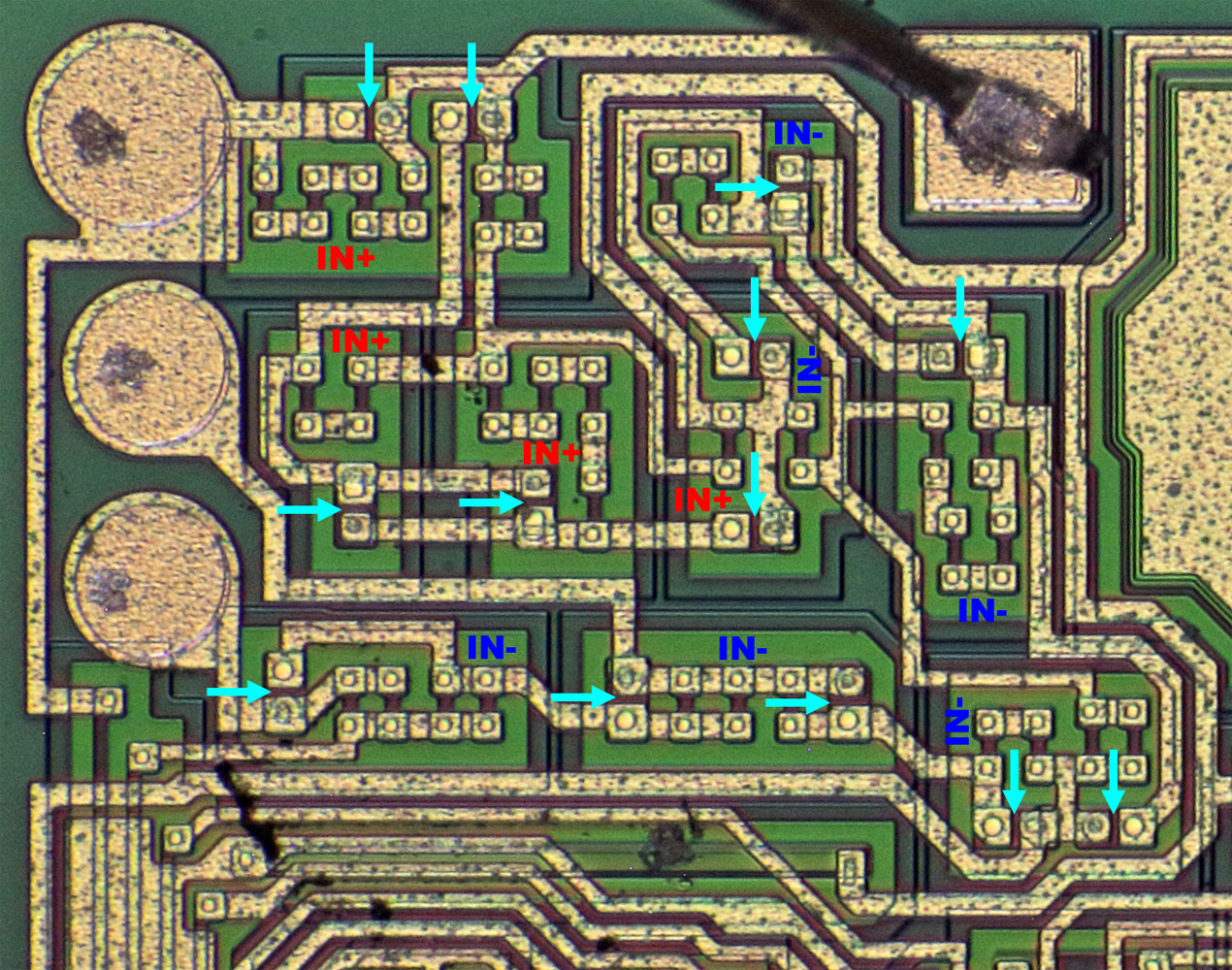

Most of the elements are easy to identify on the die. The round testpads in the upper left corner allow to adjust the offset of the input stage. The rectangular testpads on the bottom edge give you the opportunity to adjust the bias current compensation.

The input stage is arranged to have a low temperature drift. The input transistors Q1/Q2 are doubled up and arranged crosswise in the center. On the far left they keep a large distance from the output stage on the right edge, where the most power dissipation occurs. Even the collector resistors are integrated in the center at the left edge. To the right the electrically following transistors up to the voltage amplifier are arranged around the middle of the die.

The circuit corresponds mostly to the schematic in the datasheet, but there are some minor differences (light green). The pinch resistor RQ15 is found at the collector of Q15, which is the resistor referred to as Rp in the patent specification.

The resistor RQ13 is located between Q13 and Q16, this seems to be just an undercrossing of a line. At this point, a resistor has little effect on the circuit.

The 50kΩ resistor connected at one end to the clamping diodes at the input does not lead to the upper but to the lower end of the 1,5kΩ resistor above Q12.

In the collector of Q22 there is the resistor RQ22. It seems that here one wanted to create a symmetry to the second transistor of the voltage amplifier stage. Behind this resistor the line is formed into a relatively large area, which represents some capacitance to the negative supply potential (CQ22).

At the base of Q29 there is the resistor strip RQ29, but this probably serves just as an undercrossing.

Also not shown in the schematic is the transistor Q20b, which is a base current compensator for transistor Q20, which operates as a current mirror.

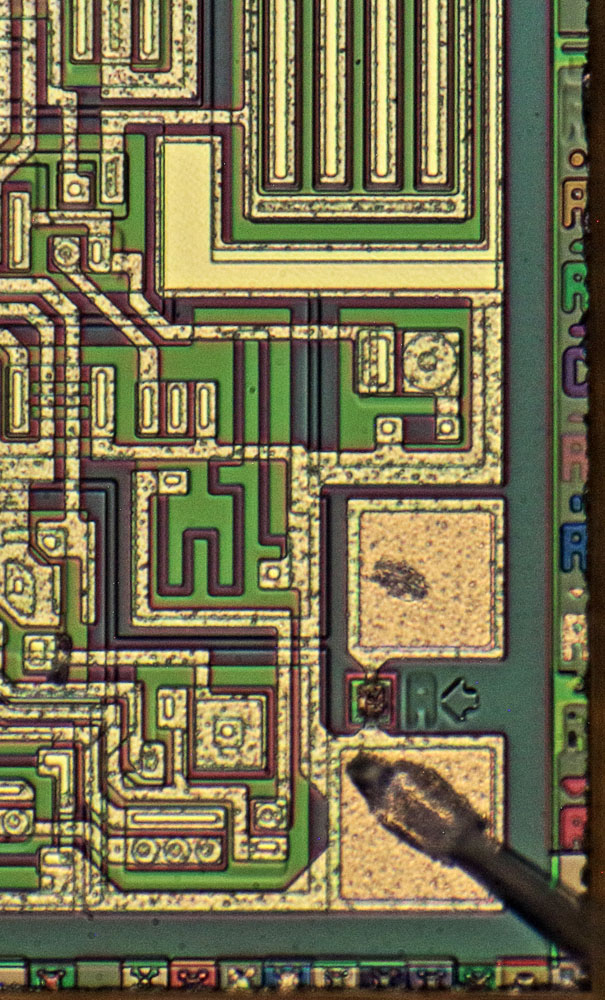

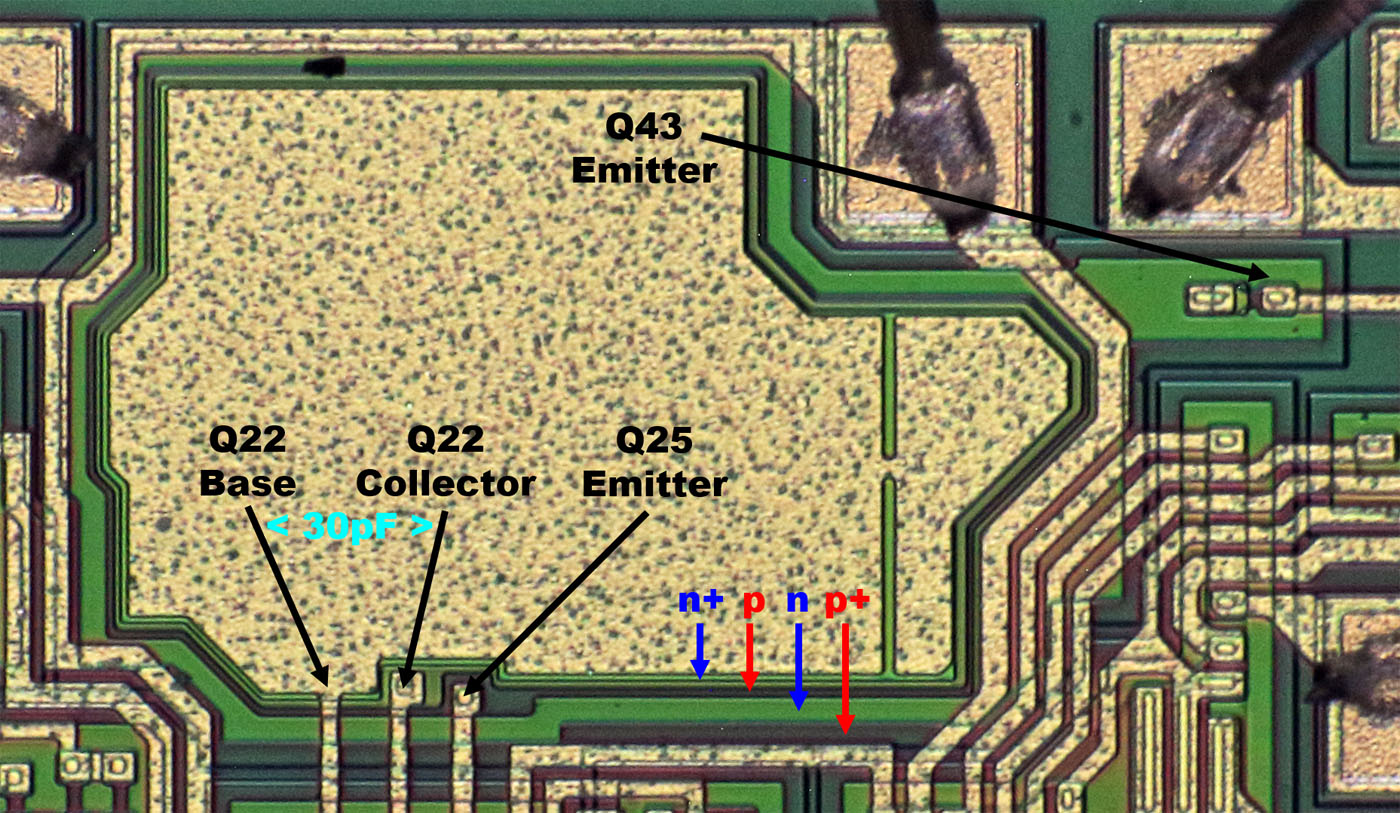

On closer inspection the large capacitor has a somewhat more complex structure than shown in the datasheet. The capacitance of 30pF is set between the metal layer and the green n-doped layer underneath. The edge surrounding the metal layer shows that there is a thinner oxide layer under the metal layer, which increases the capacitance. The metal surface has an area that can be separated via a thin contact. This makes it easier to adjust the capacitance if necessary.

The dark p-doped surface on which the capacitor is placed is connected to the emitter of Q25. Electrically adding capacitance to this node seems to have no effect on the circuit. For a safe isolation of the capacitor one could have simply connected the area to the negative supply. Probably this measure was taken to keep the parasitic capacitance to the substrate away from the voltage amplifier stage. Since it is a pn junction, this capacitance would fluctuate with the signal level and could thus cause distortion. The potential of the emitter of Q25, on the other hand, is constantly one base-emitter voltage below the potential of the collector of Q22.

The inner, green layer of the capacitor is most likely the emitter doping. It is embedded in the dark layer which is then represented by the base doping. Surrounding the whole structure is a green frame, most likely the collector doping, and finally the dark isolation frame. On the right side of the picture, the emitter potential of Q43 contacts the capacitor area. The lead is connected to a strip of the base material. Thus the collector area should be at about the same potential as the base area under the capacitor and the 30pF capacitor is thus maximally well shielded. The metal surface to the left of the Q43 contact seems to connect the collector surface to the buried collector.

If one inserts the transistors in the correct size ratio into the circuit diagram of the patent an interesting picture emerges. The current sinks Q20/Q21/Q22 are constructed in the specified ratio of 3:1:1. The same current density ensures maximum synchronism.

The doubled super beta transistors Q11/Q12 at the inputs are relatively large. To ensure the same current density in transistor Q10 it has two emitter areas. The super beta transistor Q18 is smaller but still large for an NPN transistor. The other NPN transistors Q15/Q16/Q17/Q9 are rather inconspicuous.

The symmetrical structure of the PNP transistor Q13 can be seen well. One of the collectors is led back to the base. The PNP transistor Q14 has to carry more current and is designed accordingly larger. The upper metal surface directly connects the upper collector surface with the base surface. The PNP transistor Q19 has an unusual design. Two p-doped areas, one slightly longer, are located in an n-doped area which carries the base potential.

The two 800Ω resistors above the large collector resistors are amazingly complex. The input offset can be adjusted externally by the corresponding pins. In addition the testpads can be used to configure the resistors during manufacture.

Although there are just three testpads a total of 13 Zener fuses can be triggered. We have seen these series connected Zener fuses that can be triggered selectively in the LT1013 too (

https://www.richis-lab.de/Opamp26.htm). In the LT1012 this technique has been used even more excessively. This reduces the need for testpads which saves a lot of space.

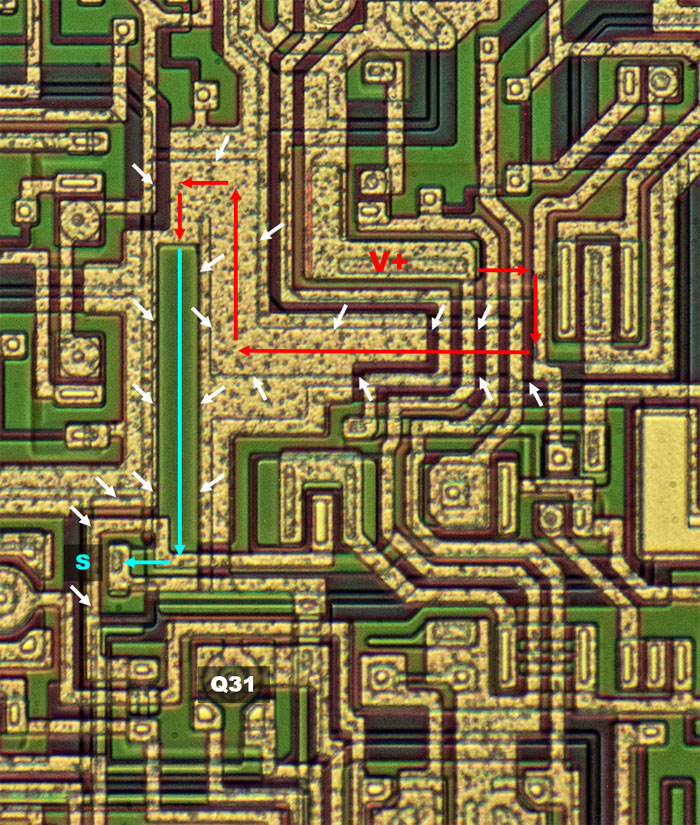

The JFET generating the reference current for the current sinks and sources can only be guessed at a very close look. A strip leads from the positive supply potential over a relatively long distance. The edges of the stripe show up through the metal layer (white). Initially the material appears dark (red). Here the collector doping seems to be completely covered by the base doping. This would result in an n-doped channel with a p-doped cladding. On the last part of the strip (cyan) is a green layer, presumably the collector doping, which appears to be contacted away from the contact to the buried collector feed line. The purpose of this division remains open.

https://www.richis-lab.de/Opamp56.htm

https://www.richis-lab.de/Opamp56.htm