I'm back, still working on fixing the vertical deflection in my Heathkit H9 terminal.

I have rewound the vertical yoke coils. I unwound the old ones, counting the number of layers and the turns in each layer. And I did, indeed, find multiple breaks in the wire. Then I rewound it, and the vertical coil now measures about 6

.

But my vertical deflection still does not work. So I'm trying to trace through the circuit, and I quickly find something I don't understand.

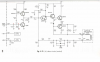

Here's the circuit for the vertical deflection:

I put my scope's ground on point G and probe point A and get this:

That's good. That's a digital vertical sync pulse. It's supposed to feed into Q301 and drain capacitor C303. (C303 will later be charged through Q302 to produce a ramp.)

But when I move my scope probe to point B, I see this:

How can that be?

Thank you,

Bob