I'm restoring three variable, electronically regulated HV power supplies: A Siemens/Ediswan Model R1103A and a pair of Marconi model TF1109A's. The units are almost identical, the Siemens/Ediswan version differing mostly in chassis layout, and has an updated circuit having a separate rectified and filtered screen supply for the series-pass tubes, whereas in the Marconi version the tubes (12E1's) are just connected as triodes.

I'm ditching all of the original capacitors and the carbon resistors will be replaced as well. Most of the resistors measure quite a bit (higher) out of tolerance, as old carbon resistors a prone to do.

With the goal of long-term reliability, I was originally planning to ditch the metal/selenium rectifiers for modern silicon, but after checking them out on my Tek 575 curve tracer and finding them operationally fine, I've decided to keep them just for the original and "cool" factor. The main, unregulated HT rail is full-wave bridge rectified by a pair of these diode stacks. Each stack is has an electrical connection to the central plate/cooling fin, so they are essentially "wired" as two series connected diodes per stack. The central connections of a pair go to the transformer secondary. I've tested each diode connection of each stack individually and they all measure very consistently the same, dropping approximately 35V at a forward current of 200mA and having no reverse current of consequence.

The rectifiers need a good clean/paint strip and repaint after rust conversion. I was about to start by just dunking these in solvent, but I'm not so sure. I know that the selenium in these things is deposited on the stacked coins in a very thin layer but I have no idea just how fragile/susceptible these things are to mechanical handling and dipping in solvent. Does anyone out there have have any idea?

This metal rectifier was once a home for wasps:

On the curve tracer:

The Siemens / Ediswan incarnation:

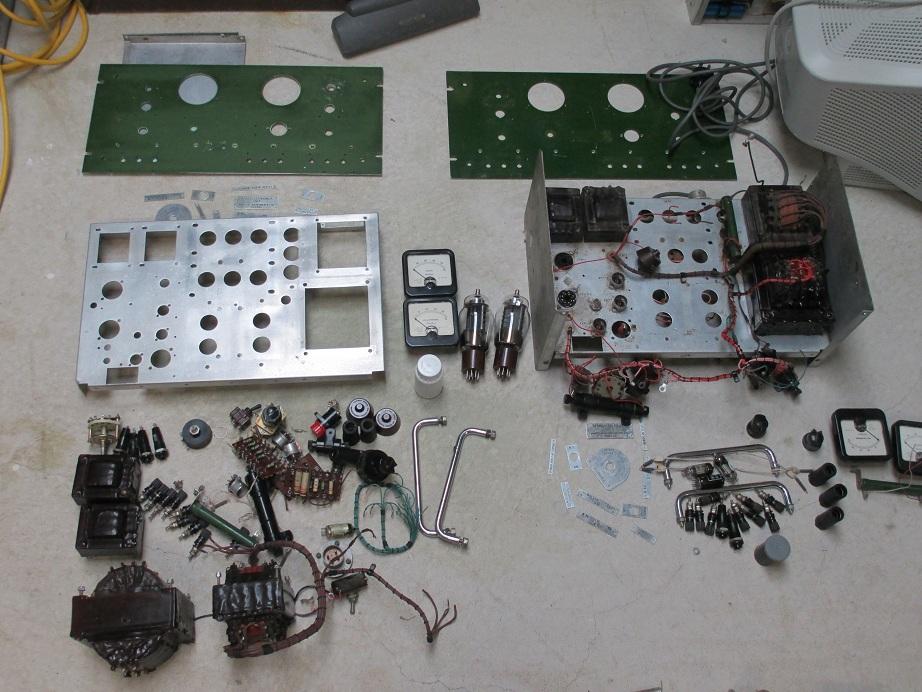

The two Marconi units almost stripped:

Capacitors for the bin: