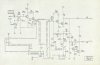

Timing Switch

Horizontal Amplifier

The oscilloscope will be back on my bench this weekend and I'll start by testing both leads of R316 and posting the results. I really appreciate all of the guidance I've received so far regarding this restoration/repair!

Also, I was recently given this Huntron Tracker but I'm not familiar with it. Maybe it's not too useful in helping to find the fault in this repair unless you have an idea?

Here's what I've decided to do.

Here's what I've decided to do. Having had such a good time restoring that Tektronix 310 oscilloscope, this Leader is going to get the same treatment. I have already replaced all of the electrolytic and HV ceramic capacitors, rebuilt the Flyback transformer, and installed new neon lamps. Starting with the CRT circuit, I'm going to pull every single resistor, transistor, and small capacitor. I'm going to replace every single part. There aren't that many. I wish I had a curve tracer to really get down and dirty with testing transistors in the event that the current "gain" is too high, but then again, new transistors of this era are cheap too, and some of the bolted-in ones I already have. Since some of the transistors that are installed have part numbers that differ from the schematics, I'll pull all of the data sheets and compare hFE specifications.

If you look at the parts legend, you'd see that the majority of resistors are labelled as 5%, others are 1%, and some are 0.5%. It appears that this scope was assembled with very tight tolerance parts. So, I imagine, it wouldn't take too many parts to wander and throw this machine out of whack. I really like those new Vishay metal film resistors that I used in the Tek scope, small and spot-on. So I'll invest in the Dale 0.1% and 0.5% for the entirety. And I wonder what those small low-voltage brown Mica capacitors have to say too? I'll measure each one to see if I find a fault.

There is something drawing too much current in this machine, and I'm going to find it!

Again, it's when I turn the Trigger Level knob to "Auto" mode that makes resistor R316 go into meltdown.

Time to dig into my 2019/2020 Winter project

*Something just popped in my mind, what effect would Silicon diodes have in a Flyback transformer circuit when they are used to replace Selenium diodes?

*Something just popped in my mind, what effect would Silicon diodes have in a Flyback transformer circuit when they are used to replace Selenium diodes? Isn't there a "voltage drop" factor to take into account?

Another observation, the power supply transformer is wired for 115VAC but I have 122VAC at the outlets in my house. That's an increase of about 5%.

Floobydust asked me to measure the filament voltage at the CRT heater pins. I read 6.58 volts, it should be 6.3. That's an increase of ~5%.

We also discovered that the transformer taps supplying R316 are 140 volts and not the 128 volts as outlined in the schematics. If this is an unregulated supply rail, I believe the voltage is higher than it should be, but I don't see a voltage reference at this point (R316) in the schematics to verify this.

I think there are errors now that are "component value" related due to the change of the power transformer's output voltages. I have used "dropping" resistors in the past to adjust filament voltages and panel lamps in my mono tube amplifiers with excellent results.

But, calculating and making adjustments to higher voltage outputs and making component changes within this scope would be well above my pay-grade!

I know very little about circuits, but I can fix things mechanically pretty well. If you feed a transformer more voltage at its inputs it only seems logical that you will over-drive the regulated supplies (additional voltage dissipation required through heat along with increased stress) and you will raise the voltage of the unregulated supply rails. Maybe, a custom transformer can be made? Or can the original transformer be modified? Or a voltage regulator be added to the outputs?

Fun stuff and just thinking out loud