I owned the PACE ADS200 for almost a year and while it is an excellent iron I needed more power as it took to much time to solder some higher power connectors (76A rated) to a two layer 2Oz (70um) PCB and since I need to solder thousands of this connectors I decided to look in to more powerful irons so that I can possibly reduce the soldering time to half and save at least a few weeks of hard work.

After checking what was available it cam down to two options the HAKKO FX-801 300W and the JBC HDE 250W.

The HAKKO FX-801 was slightly less expensive but the 70's look of the station did not inspire much confidence and the deal breaker they only have 3 or 4 available tips for this station and the largest one 6mm wide was just not enough for my current needs so the only choice was the 90's looking design JBC HDE.

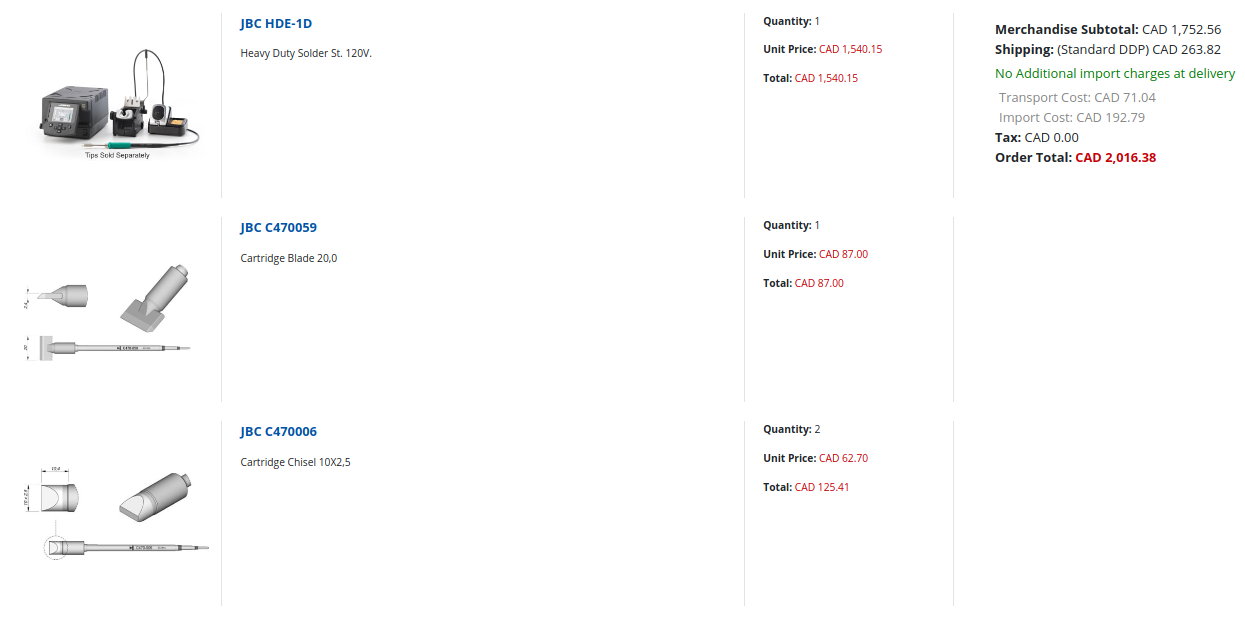

Both PACE and JBC where purchased from TEquipment and so imported in Canada.

The PACE ADS200 with a few tip's was just over 500CAD as you can see in details below

While the JBC HDE with 2x the power 250W vs 120W cost's about 4x more just over 2000CAD again including a few tip's

Bellow are a few photos and my initial impression/comments.

Already mentioned the 1970's and 1990's retro style of this two stations the JBC is a cheap feeling plastic and PACE is aluminium extrusion

Back of the PACE the AC input and the stand iron detection cable. There are a bit more options on the JBC like pedal and robot control (not useful to me at this point).

One of the very annoying things is the loud cooling fan on the JBC you may be able to see it bellow (was very unexpected to see a cooling fan on a soldering station).

Also notice the AC plugs on the bottom and I was thinking that is a great idea until I seen the cable for the iron connects on the back so you still waste a lot of space as it can not get close to the wall.

View of the LCD rotation mechanism. There is also an USB to connect a memory stick for firmware update and to save temperature/power graph's for analysis.

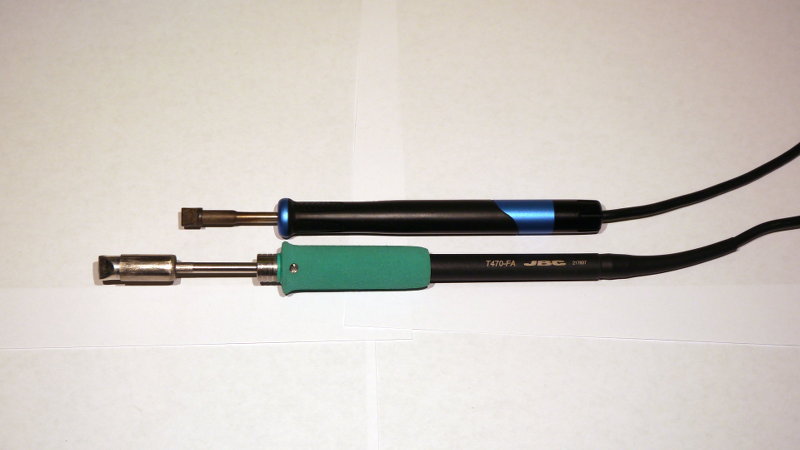

The two iron's side by side. PACE is fantastic very short distance to tip and full metal body that will not get hot with prolonged use the JBC just looks lower cost with what seems like a heat shrink type strain relief.

Likely the JBC will be less comfortable but considering the higher power is not bad in therms of size and weight. The green sponge like material on the JBC handle will likely look bad and degrade fairly fast (remain to be seen).

The PACE has the largest tip they have installed 7.95mm wide and what I used to solder two pins at the same time the 10mm wide tip on the JBC is not the largest they have but I think is not ideal for my usage. I ordered a 7.5mm one and will see if that or the 20mm wide blade I already have is the best option for speeding the soldering of those high thermal mass connectors.

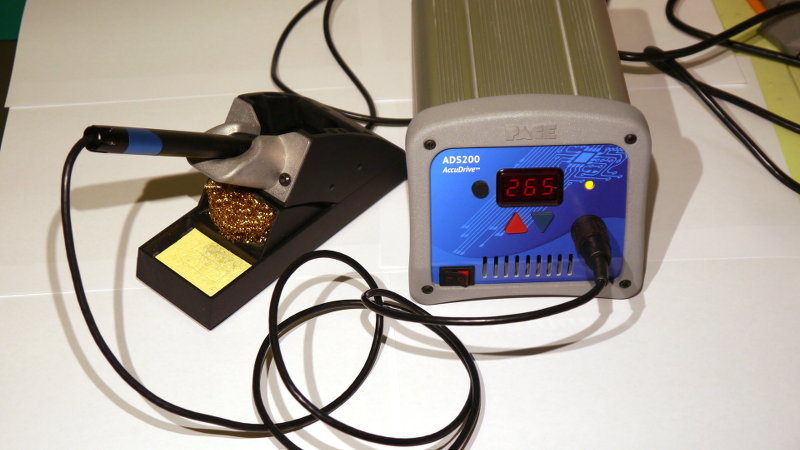

All that comes with the PACE ADS200 and is not a bad package. This is the version with optional standby switch installed in the stand so temperature will automatically be reduced when you place the iron in the stand. I will suggest you get this option

The JBC comes with a stand that of course it has a sensor to detect the iron is in the stand. In fact the iron cable connects to the stand and then there is a another cable connecting the stand to the station.

Then there is the tip cleaner that has a star cut black rubber material over the brass cleaning wool (again not a fan as I do not think it works as intended and is more in the way but it can be removed so no problem).

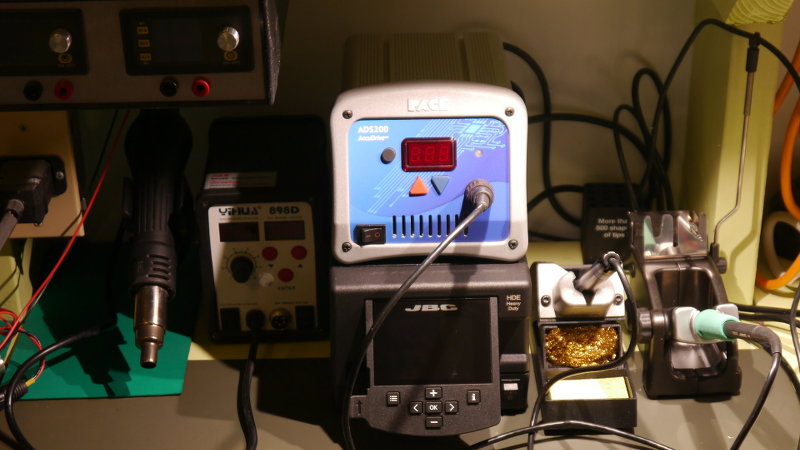

Currently installed on my desk waiting for some more appropriate tip's to do a test/comparison on thermal performance but is sure a more capable iron and it takes 250W from the AC side while heating the tip same as PACE takes about 120W

There is also the problem of effectively transferring that energy to what you want to solder. I may end up using that wide 20mm tip to heat 4 contacts at the same time.