One sleepless night with

the statement of Kleinstein in mind an idea came up...

There was an unused

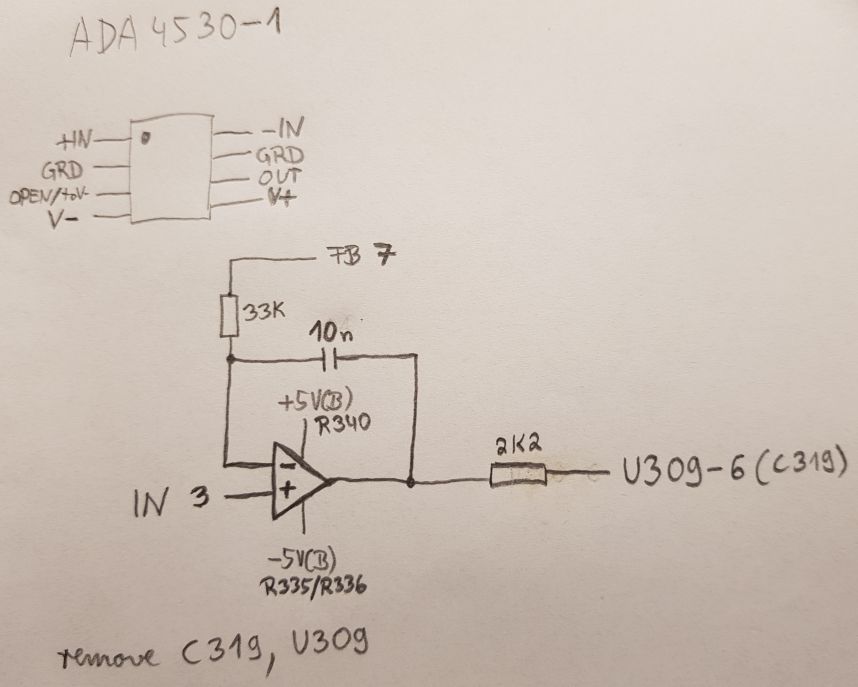

ADA4530-1 sitting on the shelf for some time - would it be possible to replace the whole input amplifier with it?

In a nutshell the input amplifier formed by Q308 and U309 is just a difference amplifier.

As Q308 was already replaced and the performance was not what could be expected (I will come back to this later), there was almost nothing to lose.

First attempt looked promising in the amps ranges, but suffered from crazy offset and random jumps in volt ranges - smells like instability.

Nice thing is the direct access to preamplifier on rear panel, so no deal to quickly hook up the oscilloscope - it's ringing like a bell, journey just ends here?

The ADA4530-1 is a remarkable device considering nearly all of its properties, for example the GBW and open loop gain are higher than that of LT1012 (U309).

The 617 manual mentions that the 10nF C319 in the FB of U309 is needed for stability - maybe just a bit of isolation at the output needed to calm it down?

I throwed a 220k trimpot in and the issues disappeared, no instability in any ranges anymore.

To get the edge value for stability the trimpot was adjusted and the value measured was ~700 Ohms.

For a bit of margin a 2k2 resistor was chosen and replaced the trimpot.

This ended in the following configuration:

The 33k should protect the negative input up to 300V (spec: 10mA max at the inputs), for the positive input there is already more than enough protection given through 100k R333 and 10Meg R334 - even for surges (R355 not present in this unit).

As there was no 10nF in 2.5mm grid at hand, for now I put a 47nF MKS in - needs further investigation what is best value.

Seems with this replacement input protection Q311 is no longer needed as the OP AMP has input protection already - my early unit does not have it anyway.

To get an impression what this ADA4530-1 delivers, the bias current compensation and the input jack was disconnected (offset compensation already leaved with the mod in this unit).

As I would not trust old 4.5 digit ADC in this unit, my 3458A was hooked up at the preamp output.

After settling, the offset was ~300µV and bias current ~48fA (calculated) - no good sign.

I continued with performance verification of voltage ranges with help of internal voltage source.

Everything in spec according to 3458A, but the voltage source seems to have like a weared out 0V, sitting at ~200mV with horrible DNL between +-50mV.

It took me a while to realize that the output of the voltage source - even if disabled - is set to 0V and enabled all the time.

As the AD7541A DAC is in feedback, I would suggest this is the source, so put a better replacement LTC7541A on the next oversea order.

The last days the big reed relays were disconnected one after each other and bias current and offset were measured, so finally only 2pA range (K312) remained.

Disconnecting K307 improved much on bias current and now it is according to expectation ~3fA.

Every disconnected relay improved on the bias current, seems all have to be replaced - this turns into a costly repair.

Offset did not significantly change - as expected.

I guess the offset is mainly due to other sources and not from ADA4530-1 - will try to measure it in circuit later.

There is some work to do and diving into details will remain to later post...

In the meantime the search for appropriate cables was done.

For now the plan is to replace the input jack with a 3 lug triax as the options for 2 lug cables/connectors/lugs are very small and an adapter from 2 to 3 lug seems not to be economic.

Has anyone done a replacement with

Keithley 7078-TRX-TBC?

For the cable I came across the

Keysight N1415A, this seems to have a much better price point in comparison to the Keithley cables, any experience with this?