Hi

I had my first stab at soldering a 140 pin quad flat pack 0.5mm pin spacing chip. I put on too much solder and had to remove most of it with solder wick. I was at it for quite a while and somewhere in the process I bent one pin - probably the wick was still attached when I removed it. I've tried to work carefully but I just couldn't see enough. So I am now shopping for some magnification (100,= euro budget tips?).

My attempts to straighten the pin back have failed. I have tried to use the top of my fine tweezers to wedge between the bent pin and its neighbor but I could not get the solder iron in to melt the solder and I did not want to force it...

Any tips or suggestions?

Thanx, Marc.

PS: I only soldered the first side so it is only held in place by this one side and a tag on the other side. Removing it may be an option - although I would like to avoid that if possible...

I do it by heating the pin that is bent then moving it in place ( xacto knife works better than tweezers for me) then removing heat while still supporting the pin until solder solidifies.

Keep at it, use a steady hand and a sharp iron tip (or something else like a sharp blade) to push the pin back onto the pad. Worse comes to worse you can always try desoldering and try again, but you're probably better off correcting it in place.

For reference, how fine pitch is it?

Tim

I have tried to take a picture but it's just too small for my camera to pick up in any detail.

Pin pitch is 0,5mm.

The pin is bent such that it now contacts the neighbor's pad.

I will try the blade tip after I get some magnification...

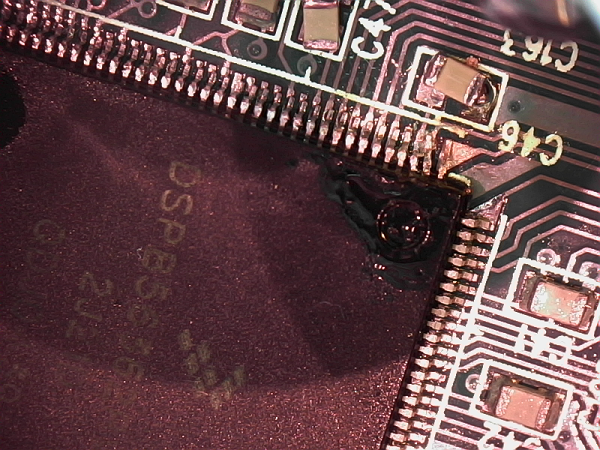

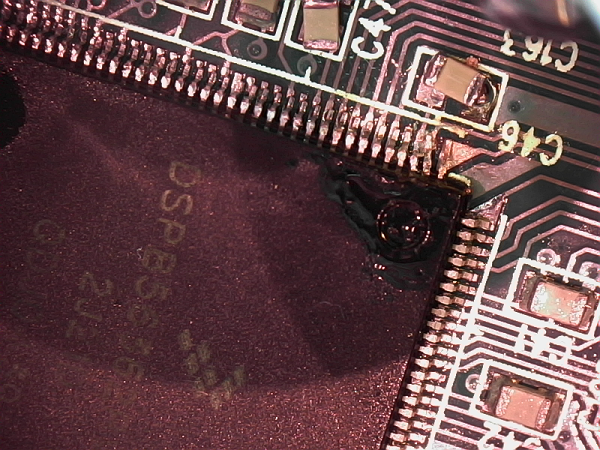

This is how it looked. (I got an USB Microscope that could take pictures like this.)

I practiced a little on a scrap HD print but that one had so many via's my flux kept spilling away to the underside...

But I think I am getting the hang of it. You need way less solder than I put on initially.

When hand soldering packages like this one, flux is your friend, especially that tacky kind (I am using ChipQuik). It is also useful to remove bridges and extra solder. You apply the flux liberally and drag a clean solder iron tip along the pads.

Yes, I've come to realize that. With enough flux the solder will 'right itself' on the pad. The excess of solder is easily removed with wick (and flux). My finding with that is that I need to turn up the heat a bit to account for the thermal mass of the wick itself - then it works fine.

The kind of flux I got is the runny watery kind...

When soldering SOIC, SSOP, QFP packages, align the chip then tack two opposite corners with solder. Make sure the pins are all aligned.

Flux up 10 or so pins, then quick wave actions (Drag OUT from the leads, not across the pins) over these pins with a 1mm chisel tip. Most of the time I only need a tiny tiny bit of solder (leaded, multicore brand, 0.27mm thick).

More practice makes perfect

.

When hand soldering packages like this one, flux is your friend, especially that tacky kind (I am using ChipQuik). It is also useful to remove bridges and extra solder. You apply the flux liberally and drag a clean solder iron tip along the pads.

A thousand times this. You just cannot put too much flux. I personally find flux pens pretty useless for soldering chips, you need actual thick "gel" flux. I've been using some "Amtech" flux from eBay that comes from China, I really doubt it is actually "made in USA" but seems to work great...

I like to use T5 solder paste, hot air pencil and a microscope when doing .5mm pins.

You apply the flux liberally and drag a clean solder iron tip along the pads.

So it's solder paste?

When soldering SOIC, SSOP, QFP packages, align the chip then tack two opposite corners with solder. Make sure the pins are all aligned.

I was struggling with tweezers and an exacto knife to keep the damn thing in place. Then I found that simply putting your thick finger partly on the board and partly on the chip will fix its position just fine for you to make the tags.

Flux up 10 or so pins, then quick wave actions (Drag OUT from the leads, not across the pins) over these pins with a 1mm chisel tip.

I have tried dragging across the pins and that works fine - just don't put any pressure on your tip. Oh and ya, my tip is a bit big 2.2mm but it works - would probably work better with smaller tips (wasn't able to find a smaller chisel tip for my solder station)...

I like to use T5 solder paste, hot air pencil and a microscope when doing .5mm pins.

Yes, I have seen YouTube videos that demonstrate that - looked real easy. I went with the conventional solder (I use 0.5mm 5 core 60/40) and flux because I don't do this every day and as I understood, solder paste has a shelf life...

I decided to desolder the chip and fix the bent pin. Unfortunately that did not go very smoothly. I had some more bent pins and a (one) pad that came lose from the PCB. I have managed to straighten everything out using my new USB Microscope - good practice there too - but it kept me busy the rest of the day... Ah well.

Thanx, for all the suggestions. Appreciate that.

I try to use a 1-2mm chisel tip. The bigger the better sometimes.

If it's a large chip we were always told to hold down using kapton tape .. but i've used my finger or a pen with blu-tac on before.

The first part of this video is good:

Dragging across the pins then wicking off excess isn't a great idea... the pins can be thermally stressed. Drag out, the solder always follows the heat and you will end up with less bridged pins.

You apply the flux liberally and drag a clean solder iron tip along the pads.

So it's solder paste?

No, it's just flux, no solder, but in a gel form. Being gel it's stay in place better than the liquid flux.

I am using this one

http://amzn.com/B001KADQZU . Recently I changed the needle to one with smaller ID for more accurate dispensing but the stock needle should be just fine. Drag soldering is done well with 'hoof' shape tips. Some tips are even concave so they can hold more of the extra solder, but again, not required.

Drag soldering is done well with 'hoof' shape tips. Some tips are even concave so they can hold more of the extra solder, but again, not required.

Hoofs are easier to use than a chisel, but I find the dedicated drag soldering tips are even better.

Unfortunately, it seems they're not available in all markets (i.e. Hakko's aren't available everywhere due to Trademark issues IIRC).

As per flux, liquid works just fine as well IME. The trick is using enough of it. You don't have as much precision control as to where it goes of course, but it's easy enough to clean up, so long as it's not been cooked to dark brown crud.

I dislike the gel flux.. it just seems a bit dirty. I spread on no-clean flux like it's going out of fashion before every time the iron touches the board

Just gotta remember to clean it up after.

.

.

Unfortunately, it seems they're not available in all markets (i.e. Hakko's aren't available everywhere due to Trademark issues IIRC).

Unfortunately, it seems they're not available in all markets (i.e. Hakko's aren't available everywhere due to Trademark issues IIRC).