Many thanks to all, guys! Your shared experiences will be for sure a great benefit for everyone. You gave me so many useful info and I thought that the best thing would be to write a long comment divided into categories. I also changed the title because when an user enter such topic, he really can say to know everything there is to know.

CLEANINGYou can probably go for at least a year or two, just wiping with a damp cloth from time to time before requiring anything stronger. For sure, if you don't clean up frequently, then it will get harder to clean as thoroughly over time.

The mat will inevitably get splashes of IPA over time, and that doesn't seem to harm it, but I can imagine it would be good to follow the instructions for the specific mat chosen, especially if it's in a lab environment.

Personally, I've seen no deterioration (I don't have the correct tools, but I have an insulation tester, and I measure an approximately similar value in the heavily-worked area as in an unused corner area. I think if you buy a decent mat, you can consider its condition and life to be a solved problem for at least half a decade to a decade.

A wet rag is what I usually use. Perhaps some IPA if some rosin splashed on it?

Thanks! So, the main rule is to always clean (

immediately) through wet rag/damp cloth. If doesn't work, the next choice must be done carefully. Although IPA (or lysol) has been

showed to be safe, some

sources strongly discourage its usage. It seems this mainly depends from how a mat has been manufactured. I'm not sure if a generic (and expensive) ESD mat cleaner is safe on all kind of mats. So, the most wise thing to do is to follow the instructions for the specific mat chosen as said from shabaz (or ask to the distributor).

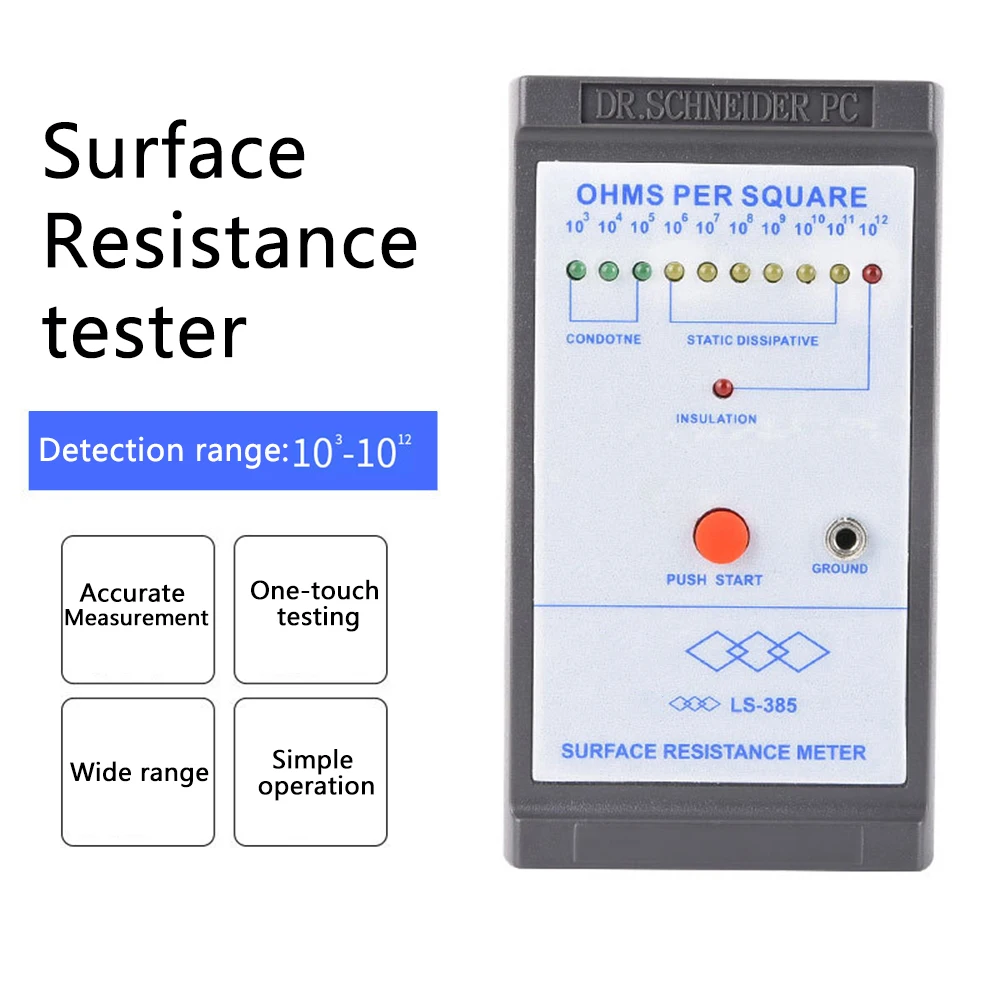

Shabaz, is this the tool you use?

The inability to detect the end of a mat lifespan and deteriorated areas (for whatever reason, cleaning included) is something that I have not considered. I'm wondering if I should buy one? Is it not possible to perform the same tests through a good quality DMM?

HOME ELECTRICAL SYSTEM SAFETY (SHOCK HAZARD RISKS)If your home electrical system is good, it's over-worrying if you think the ground connection will cause an electric shock risk. You'd feel it first with any metal appliance, e.g., a kettle.

When you say "I just trust the earth connection is good" you mean the electrical system of your house and not the ESD mat system, right? If so, I should be in the same boat since the electrical system has been renewed less than 10 years ago (...) However I still don't feel safe. What if something breaks in the home electrical system (or in the ESD system)?

Well, I wouldn't trust any earth connection before checking it's really good. I mean, here many buildings are more than 100 years old. Most of them converted to 220V in the 1970s. Even if electrical installation is "new", it doesn't necessarily mean it's "good". Even if it's supposedly "certified". YMMV. Some years ago, we deployed a neighbourhood wifi network using Ubiquiti gear. It turned out that Ubiquiti gear really needs good earth connection and surge protection. First year, we lost 20% antennas, mainly for earthing problems. One of the nodes needed to have its gear replaced each 2-3 months. Neighborhood electrician lived in that building.  I insisted and insisted again in having a new earth connection. And having it checked good. Problem solved.

I insisted and insisted again in having a new earth connection. And having it checked good. Problem solved.

Since then, when going to a new deployment point, I always carry with me a surge protector...(details moved into the next section)

Or another device discharge to the ground while I'm connected to the mat? You don't have such concerns?

No, you are getting paranoid now. Once the current goes to earth, it's gone. Thing is, current must not go to earth through your body.

Well, if you are a cow in the wild, and your forward legs are a meter or more from your back legs, and lightning strikes near enough you, then there probably will be some potential between your fore and aft, and some current would flow trough you. Probably enough to kill that cow. Or so I have been told.

But you are not a cow in the wild when the storm thunders, your feet are not at a meter from each other (think of birds meeting in HV transmission lines) and 220V isn't a lightning strike. Moreover your electrical panel should have a GFCI (not sure about the acronym -we call it a differential here) that should work as soon as it detects there is less current getting out your home as is getting in.

You'd feel it first with any metal appliance, e.g., a kettle. Even if there was a fault, you're protected to a degree through a 1 Megohm resistor inside the earth bonding plug.

If I have understood well, even if an electrical home system is certified (like mine) there's still no guarantee that "it's good", but this only applies to ESD system safety and not my health safety. At worst, some connected device can break (like happened to you with 20% of antennas lost), but no risks at all for my own safety. If I'm not wrong, 1Mohm resistor will protect me and the ESD system from any risk. Resistors can go bad, the value can shift and one could end up with an open circuit (I will enter into more details in the next section which seems more appropriate).

I will have to check better my electrical panel to see if it has such GFCI thing, but what I can say for sure is that when multiple devices are connected and demanded power is more than the one we have established in the contract, the whole power supply is interrupted through an automatic switch. We can switch back again, but the whole power supply will only return and become stable when we ensure the demanded power is within the limits. Not sure if this has some relation with the safety mechanism you're talking about or it has more to do with the company not happy to provide extra kilowatts for free. I really need to check this.

I think mine is more of a mental problem than else. It's just the idea (more than the real risk) of being connected to an AC socket that makes me nervous while working and in such kind of jobs calm and firmness are essential factors.

So, if GFCI is the only one thing I should check in order to ensure my own safety, I'm perfectly fine and I will post here my findings as soon as I can.

ESD SYSTEM PROTECTION MEASURES250V though a 1meg resistor is 250uA, a quarter milliamp, maybe good for a tingle? Certainly nonlethal, though if you're buying straight from China it would be wise to open the adapter up and make sure a large resistor of sufficient voltage rating is used, if it's some little 1/4 watt thing upgrade it before use.

Monitoring seems like massive overkill to me unless you're building man rated flight hardware, high reliability medical devices, etc. Not sure what the first is doing but the second more expensive device appears to be a $5 outlet tester (which are far from infallible) with an added earth jack, run right between live and neutral?

If I have understood well, you're saying that whether I use an adapter (with or without built in 1M resistance) or not, the only needed thing is the wrist strap end point attached to the pin ground of the wall socket.

I don't think Eleshop's kit has that 1 Mohm extra resistor. The mat itself should have quite a lot of resistance (1 Mohm - 1 Gohm), and should discharge any potential quite slowly, avoiding any spark and damage. But if you want to have it, please feel free to do so.

I rather prefer having that connector under the table, next to me, than where the guy in the video puts it, near the wall. I think that way a)it will impair their movements too much, and b) it will be sweeping his work surface with each movement of his right hand. I have the connector on my left. No way I'm going to connect it to my ankle, I would have to fold my back each time I need to go far from the ESD place and then again when I come back. But, probably his backbone is in better condition than mine.

...First year, we lost 20% antennas, mainly for earthing problems. One of the nodes needed to have its gear replaced each 2-3 months. Neighborhood electrician lived in that building.  I insisted and insisted again in having a new earth connection. And having it checked good. Problem solved.

I insisted and insisted again in having a new earth connection. And having it checked good. Problem solved.

Since then, when going to a new deployment point, I always carry with me a surge protector which also has a LED to indicate earth connection is good. If that LED doesn't turn on, earth connection is bad, then node deployment gets delayed until a new/repaired earth connection is checked good. From that point, it's now rare to have any antenna suddenly dying. Speak about >95% incident reduction.

You could look for APC brand. We got ours in Leroy Mierdin for about 40€. Because they also arrest surges -and it's really efficient- these surge protectors get a place in each new rural node, where summer storms and lightning strikes are a real problem. Not really needed in a city, but I have one of these at home... Anyway it's not going to protect your gear and you against a direct/near lightning strike but it will avoid damage by surges in the electrical network caused by lightning striking at some kilometer(s) away. It uses MOVs, thus you have to think on it as an expendable item that will need replacement in some time, very probably, years. But you can just replace the MOV. Do it on some schedule, before it dies and your gear gets not protected anymore.

That way you will know if your earth connection suddenly fails -not really important after checked good. But, if needed for peace of mind, you'll know you have your stuff safe not just from ESD but also from surges BTW.

Don't do that crappy thing to get a cable directly connected to a plug in the wall. No doubt it surely will work, but you have ESD plugs for that. Put just the earth connection in a plug, get the plug into the jack. Done. Cleaner.

Eleshop's ESD starting kit was good enough for me. It has all you'll need for ESD, and for 40 € it seemed good enough to me. It doesn't have the intermediate banana station, but it has a plug with conector. That plug gets into a jack strip screwed under the table. In turn, that jack strip -and others- get plugged into the surge protection strip. YMMV.

OK!

No cable directly connected to a plug in the wall, but a member of the community does not

recommends socket adapters because banana plugs do not fit securely in AC outlets and I suppose he refers to the yellow ones (the most diffused). How I can avoid such risk? I will try to find the adapter below, it should be much cheaper, but I doubt it has a resistor. The yellow ones are very expensive.

So, adding an extra resistor could not be needed if the mat is "1 Mohm - 1 Gohm" (I will ensure that). If not, adding another one is recommended as an extra level of protection (for my body and the system itself). Is it safe multiple resistors? The values will become altered, is still safe?

If I will end up buying an extra resistor separately, I have the option to choose a larger one (and I suppose would be better). What is the maximum range I should stay within?

Yes, BrokenYugo, a monitoring system may sound overkill, but without it I'm still unable to identify failures or abnormal ESD status (unless I continuosly check with a DMM). The only reason for which I decided it's worth is because I found one very cheap.

I will enter more details on the black one I initially posted (the yellow one is more expensive).

Tatel, is

this the surge protector you're talking about? From the photo and the way you described it seems to be the same.

This is the

link to the product page (and another

one with additional details) while this is a

link to a video showing its usage. The official

product page from what seems to be the manufacturer (or main distributor).

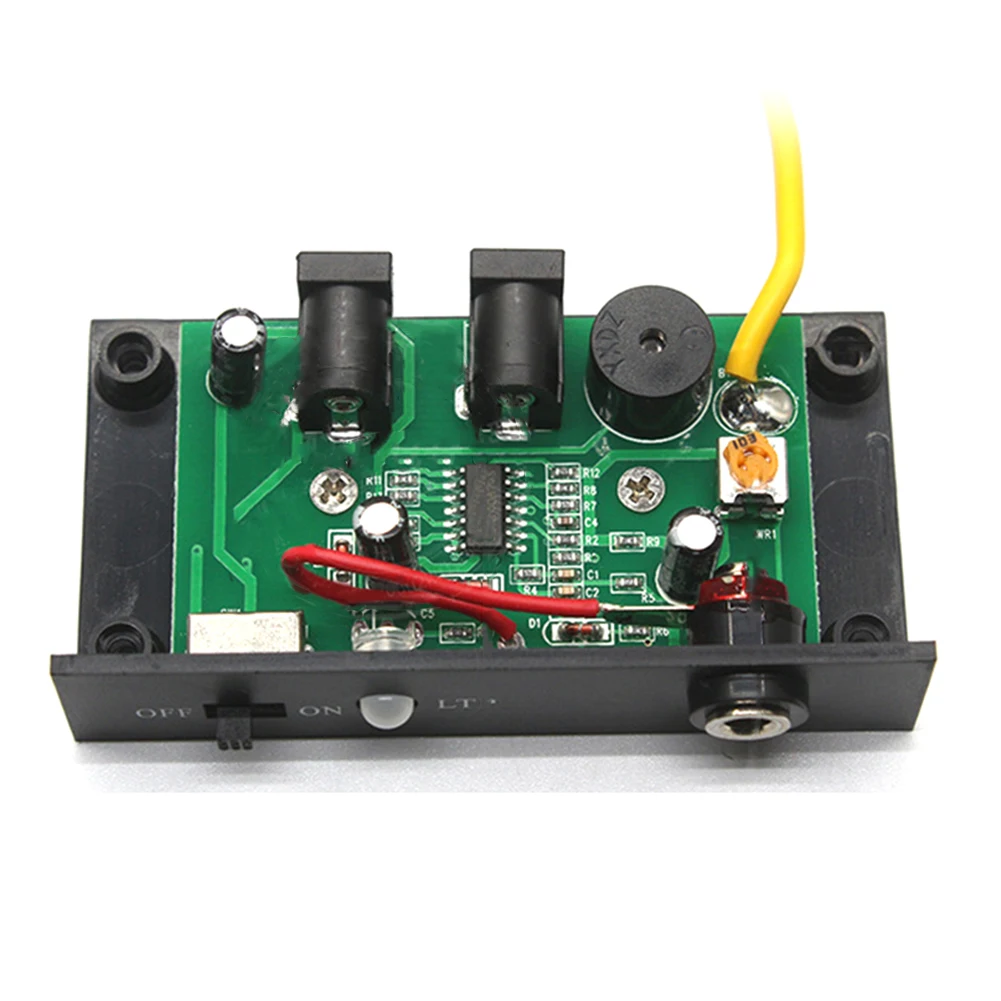

The internal:

Do you see any safety measure? Should I still add the extra resistor? It seems to have more features, but it's not fully clear to me. Since you already have something similar, may be you can check better what can do and cannot do.

DETERMINE THE NUMBER OF JACKS NEEDED BEFORE ANY ORDERIn time, you'll probably need a lot of jacks for so many devices you'll get. You could deploy them from this protected jack strip in a star shape and have it all protected, too.

This is another thing to take well in consideration before doing any order. If I am correct, multiple jacks are needed if multiple operators are needed in order to share the same workstation (and save money from having to buy additional single jack items later).

And this becomes more evident when the system becomes more complex (like the addition of the monitoring system above).

However, if the workstation is only intended for one operator (like my case) a single jack should be fine and determine the correct size of the mat should be sufficient. In my case I think I should go with 900x600, it should be enough to work with multiple boards and devices.

Are these the correct things an user should first evaluate before any purchase?

HEAT RESISTANCEEleshop - ...heat and solder resistant...Heat resistance: 400D (C°??)

Perhaps Fahrenheit... I once put 5 watts through one of these aluminum-bodied resistors, rated for 5 watts... and a couple minutes after, found it had melted the handle of one of my screwdrivers down to the metallic part inside the handle. So I would say it got about 200ºC? One corner of that resistor left a brownish tarnish on the ESD mat. That way I learned at least three different things simultaneously.

Thus I wouldn't say it is heat-proof, much less 400ºC-proof. You don't want to put your hot solder iron on it.

But it resists solder splash like a duck's feathers are waterproof. No problem. If you do stupid things, like I did, this is not ESD mat fault. Stands for solder irons exist for a reason.

So, this demonstrates that the advertised heat resistance is real. It remain to understand if it is really needed. In case of solder irons I can only think an high heat resistance can help when the iron drops accidentally from the stand.

When using a soldering iron I don't see many problems, but when replacing an smd IC it's another story. The heated area is larger and temperature can reach 400 and more degrees Celsius. Did you found your mat to be resistant even for such high demanding tasks?

I'm not sure if you mean soldering or desoldering, with iron or air station, but if you put 400ºC on your board, you'll probably will cook that area of the board and quite a few components. Unless you have quite some experience, but this usually means you already cooked some boards, I fear.

A desoldering gun and or hot plate would probably be in order. With the hot plate you can put say 100ºC on your board. That temperature shouldn't damage anything. Then applying some more 150ºC locally to desolder some component with the iron/tweezers/hot air gun will be much, much easier. If using hot air, you should protect from heat the components next to the one you are replacing. You can use for that kapton tape, aluminium foil, whatever. If you use through hole components, a desoldering gun comes really handy.

Anyway, the matter is to get enough heat, fast enoug, into the joints. So the solder melts before the heat can creep into the component's body, the board, etc. That way neither the components nor the board nor the ESD mat should get damaged. Check component's datasheet to see how much temperature/soldering time they are able to survive. Usually it is something like 250ºC for 10 seconds, not more. I would say your ESD mat will also survive that, no problem.

But, if you are unable to put enough heat fast enough, then heat will probably creep out the joint and ruin something.

400C? If you manage to heat your board to 400C, it will literally be bubbling and producing large amounts of extremely pungent smoke as the epoxy decomposes into black goo. (I’ve only seen this happen once, when an infrared preheater’s controller failed and left the heating elements at full blast.) The fact that your soldering iron tip is 320-370C does not mean that the board gets anywhere near that hot! In soldering, your goal is to get the joint to just above the melting point of your solder. So if you’re using, for example, lead-free solder that melts at 227C, your actual joint temperature will be perhaps 250 or 270. Similarly, since I suspect you’re talking about hot air, if you need to use 400C air, you’re likely doing something wrong. That high temperature can easily damage the board, and even more easily damage components.

This is a really good point guys and sorry for not having given enough details.

I use a very old (and I suppose, of very low quality) 852D soldering station (

). I'll have to buy something more decent in the future.

I use a fixed temp of 389C° for every job and the melting point usually occurs after one second, more or less. With a lower value there is a much longer delay before I see some sign of melting and it makes the work harder (it doesn't fully melt). I never calibrated the station, so I'm not sure this is the real temperature.

I only use welding solder combined with no-clean flux (this one in every operation).

Edit: cleaned the accurate soldering-desoldering description (I was going out of topic) and moved into a more appropriate

topic.

I'm unable to determine how much temperature effectively can reach the mat or the board, but I have to believe it is much less that 389C° (supposing the station show the correct value). Perhaps I should be more scientific and buy some heat measurer rather than using my sixth sense.

SOLDERING DIRECTLY ABOVE THE MAT VS HELPING HANDS or VICE (HOT AIR ONLY)Regarding vice, that's the only good way that I know to support a board with no movement, if there are components or wire ends on the other side of the board, or if you're making measurements, and don't wish to accidentally short to a stray wire clipping fallen on the ESD mat.

So, I am wondering if they all performs the same in terms of heat resistance and consider the advertised high resistance temperature as a way to show what is a standard feature as an exclusive feature of the brand. When using a soldering iron I don't see many problems, but when replacing an smd IC it's another story. The heated area is larger and temperature can reach 400 and more degrees Celsius. Did you found your mat to be resistant even for such high demanding tasks?

This is another reason for using helping hands or an FR-4 board instead of working directly on the mat: you will run into a different problem long before melting or scorching becomes a worry. Namely, warping: the mat will expand when warm. So if you put a board directly on the mat and start heating it to soldering temperatures, the heat transferred to the mat will cause it to expand there, and since it has nowhere to go but up, the mat will arch upwards and create an unstable work surface. The mat will flatten again once cool, but you can’t work this way!

...For hot air, you want the board suspended off your bench, so the bench isn’t acting as a heatsink, either. (Ideally, you’re suspending the board over a preheater.)

From the reports I commented in the previous section seems to be that when a mat is advertised as 440C° resistant it is because it really is (I can't imagine known and reputable brands like the listed ones doing false advertising). If the problem you mentioned occurs even with a such high heat resistance I really don't know. When a brand states the maximum temperature supported I would assume they means without any physical alteration, but who know. One should verify this directly on the field to be sure.

Any particular reason that forced you to use a vice rather than placing the board directly on the mat? And are you sure a vice will not break ESD safety?

Convenience? Usually while soldering, one wish to have more than two hands. I don't think a third hand should break ESD safety unless there is some plastic breaking the circuit to the mat/earth

... and helping hands are made of plastic, so I'm not sure on safety.

Helping hands has always been an item I wanted, but then, once I saw the silicon pad (and ESD mat with anti-slip) I didn't found any reason to buy. I can hardly see how can help with hot air where even a small movement can cause misalignment. Anyone of you are using this tool and find it useful for some jobs?

A vice looks more reliable, but a pre-heater seems the ideal solution as tooki said. I can be wrong, but with a solder iron, both vice and helper hands to me seem useless.

PREHEATERThe fact that your soldering iron tip is 320-370C does not mean that the board gets anywhere near that hot!

Yes, I'm also convinced about this. However, I'm still asking myself if I should improve my equipment and try to get into lower temperatures.

Your goal should be to preheat the whole board gently (e.g. to 100-150C) using gentle heat, so that you can then use a much gentler 300C or so to quickly locally heat the chip you need to remove. The preheating of the whole board prevents it from acting as a giant heatsink. For hot air, you want the board suspended off your bench, so the bench isn’t acting as a heatsink, either. (Ideally, you’re suspending the board over a preheater.)

I never used a pre-heater and I asked myself multiple times if I should.

Edit: cleaned all the details (I was going out of topic) and moved into a more appropriate

topic.

ADDITIONAL (AND NOT MANDATORY) STUFF- ESD lab coats

One last thing: if you live in a place where relative humidity is usually at/over 70%, probability of ESD is small. If you live in a dry place with RH at/less than 50%, probability of ESD discharge is bigger. Avoid wool and synthetic clothes.

However, I do keep ESD lab coats at home, although I only use them when assembling something critical, and have several around for anyone else nearby to wear, too, because I don't know what clothes they will be wearing.

This is a good point. We all wear synthetic clothes and is easy to hear sound of them crackling (especially when we undress). However, I have not well clear how clothing affects the ESD system. I'm correctly to assume that they are useless if we only touch board and mat through bare hands or our skin?

Anyway, they are cheap and I don't see any reason to avoid them. Many people suggests to wear the right clothes, at this point I find much easier to wear a lab coat without change clothes each time (I live where humidity is over 70% and I still hear sound of them crackling).

There are also antistatic caps, but to me seem excessive. However, I have been recommended to tie back long hair as it also can become charged and create induced charges. - Antistatic gloves

Time ago I purchased such gloves and of good quality. Given the ESD system I'm going to build, I'm wondering if they are useless or can be considered a great additional layer of safety (or they can anyway be used in a different context).

- ESD Floor mats

Here has been suggested that they are not needed with hardwood floors (may be an hardwood sheet for non hardwood floors?). I suppose a dedicated ESD floor would need to be grounded and this means wearing an ankle strap. This is going to be much! Unless someone can suggest something easier, I find the usage of ESD floor mats unfeasible, but if an hardwood sheet can help a bit, then it could be worth:

- ESD-safe component storage

You still (perhaps) need to think about ESD-safe component storage, etc.,

ESD sensitive components already come in antistatic bags. Do you refer to some sort of organizer where to store the entire stock of components? Is it any good a cabinet made of plastic like the below? They are not marked as esd safe.

ALTERNATIVE TO WALL SOCKETBefore opening this topic I saw in the web such statement:

"To prevent built-up static from transferring from you to a sensitive computer component, you'll need to discharge the static into something more durable. In most cases, this is a metal item that is either touching the floor or touching a series of items leading to the floor."So, I have done some experiments and I come out with the following two options (only difference is the shape and weight of the metal object):

The measurement returned the same value in both the objects. The length of each object is customizable.

I have to suppose this is completely useless, right? Other people recommended a connection to the soldering station. I posted a picture of mine and it doesn't have an earthing point built-in (I suppose that a connection to the metal case through an alligator clip is not going to work).

In any case, the ESD Association recommends the wall socket and it must be for valid reasons if I only see ESD workstations only connected in this way. I posted the above picture just in case someone think to do the same.

PATIENCE AND PERSEVERANCE IS THE KEY WHEN CHOOSING A MATI don't think Eleshop's kit has that 1 Mohm extra resistor. The mat itself should have quite a lot of resistance (1 Mohm - 1 Gohm), and should discharge any potential quite slowly, avoiding any spark and damage. But if you want to have it, please feel free to do so.

Eleshop's ESD starting kit was good enough for me. It has all you'll need for ESD, and for 40 € it seemed good enough to me. It doesn't have the intermediate banana station, but it has a plug with conector. That plug gets into a jack strip screwed under the table. In turn, that jack strip -and others- get plugged into the surge protection strip. YMMV.

This seems to be one of the best option and price can be further reduced to €25 if one already have all or some of the accessories. How much did you paid for shipping? Their estimator tool does not work and I know that for an item like this shipping costs can double the price if they use an expensive carrier.

Although the real heat resistance is unclear, the damage you described could have been (probably) avoided in mats with higher resistance. Of course, what happened to you is supposed to never happen if one is careful enough, but things happens even when we take all the possible precautions.

Did you had chances to see how it react to other threats?

With a little more (€ 38) there is also

Elmi brand (440C° heat resistance). The company is italian and since I live in Italy shipping is just € 8.90. Both Eleshop and Elmi mats will probably end up to cost the same. How you would compare the two?