Here you can see the germanium power transistor OC864A, which was developed in the Funkwerk Erfurt but never went into series production. Only a few sample exist in the Thuringian Museum of Electrical Engineering (

https://www.elektromuseum.de). The following background information also comes from this museum.

In 1959, the VEB Funkwerk Erfurt (FWE) ceased production of transmitter tubes. The capacities freed up were used to start developing germanium power transistors in the so-called Zentrallabor für Empfängerröhren (ZLE). An important basis for this work was a Soviet documentation. In addition to the necessary dimensions of the germanium crystal, it described how to etch the material, which alloy materials to use and which geometries to aim for. Alloying was carried out in a graphite mould under vacuum. The design of the alloying furnace was also taken from the Soviet documentation. However, the optimum temperatures and times for the alloying process were missing and had to be determined from tests. At the end of 1962, after the development had been completed, the results were transferred to the Halbleiterwerk Frankfurt Oder (HFO).

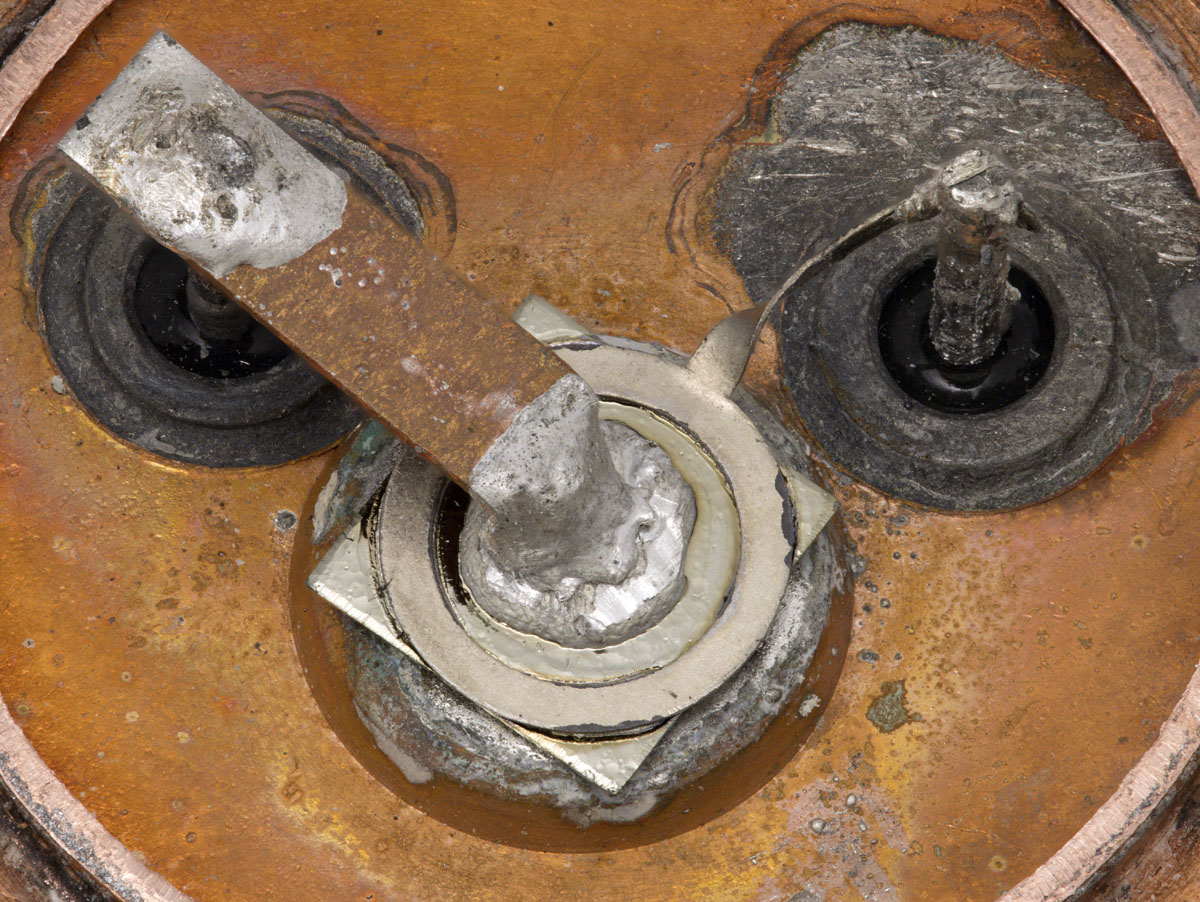

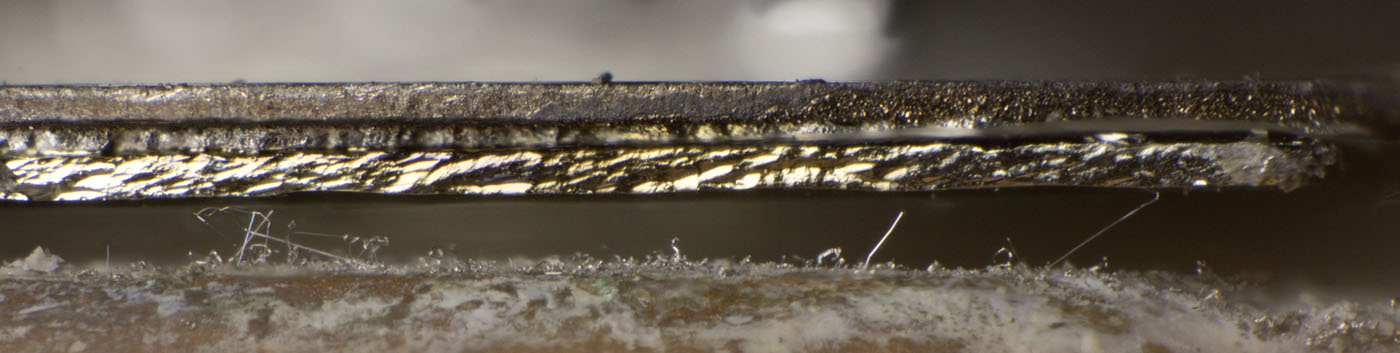

The transistor housing is made of copper. The base plate is 3 mm thick.

Letters are stamped into the base plate to identify the pins for the base and emitter. The indentation creates a socket on the top, on which the actual transistor is located.

The construction and connection technology is not unusual for a germanium power transistor. A ring-shaped electrode contacts the germanium platelet and thus transmits the base current. The emitter current is supplied in the centre.

The quality of the solder connection between the base pin and the contact plate is very poor.

The germanium crystal has an edge length of 5,6mm. An edge length of 6mm should enable a power dissipation of 25W. An edge length of 4mm was intended for 15W transistors.

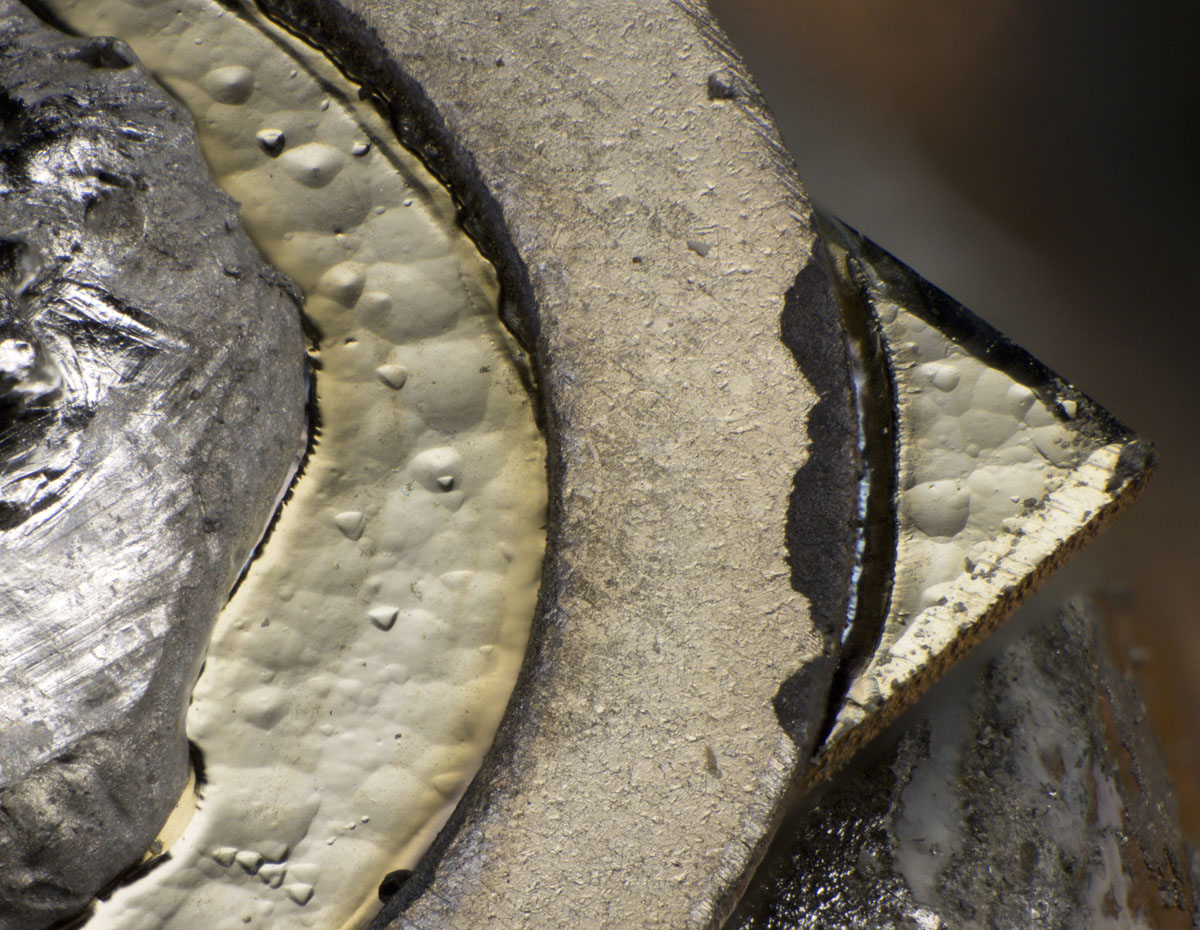

To produce the emitter shown here, an indium-gallium mixture was alloyed into the germanium. Pure indium was used at the collector. It is easy to recognise that there are two metal layers on the germanium platelet. The lower element is the alloy material that forms the emitter. The emitter contact was soldered onto this with a solder that melts at a low temperature.

The germanium disc was manufactured at the Halbleiterwerk Stahnsdorf, which belonged to VEB Halbleiterwerk Frankfurt Oder (HFO). The surface shows the familiar structure resulting from the etching process used to clean the surface. The edges appear to have been reworked in some way. The surface structure changes in these areas.

The germanium disc is approximately 0,12 mm thick. There is a 0,05mm thick solder layer and the 0,10mm thick base electrode.

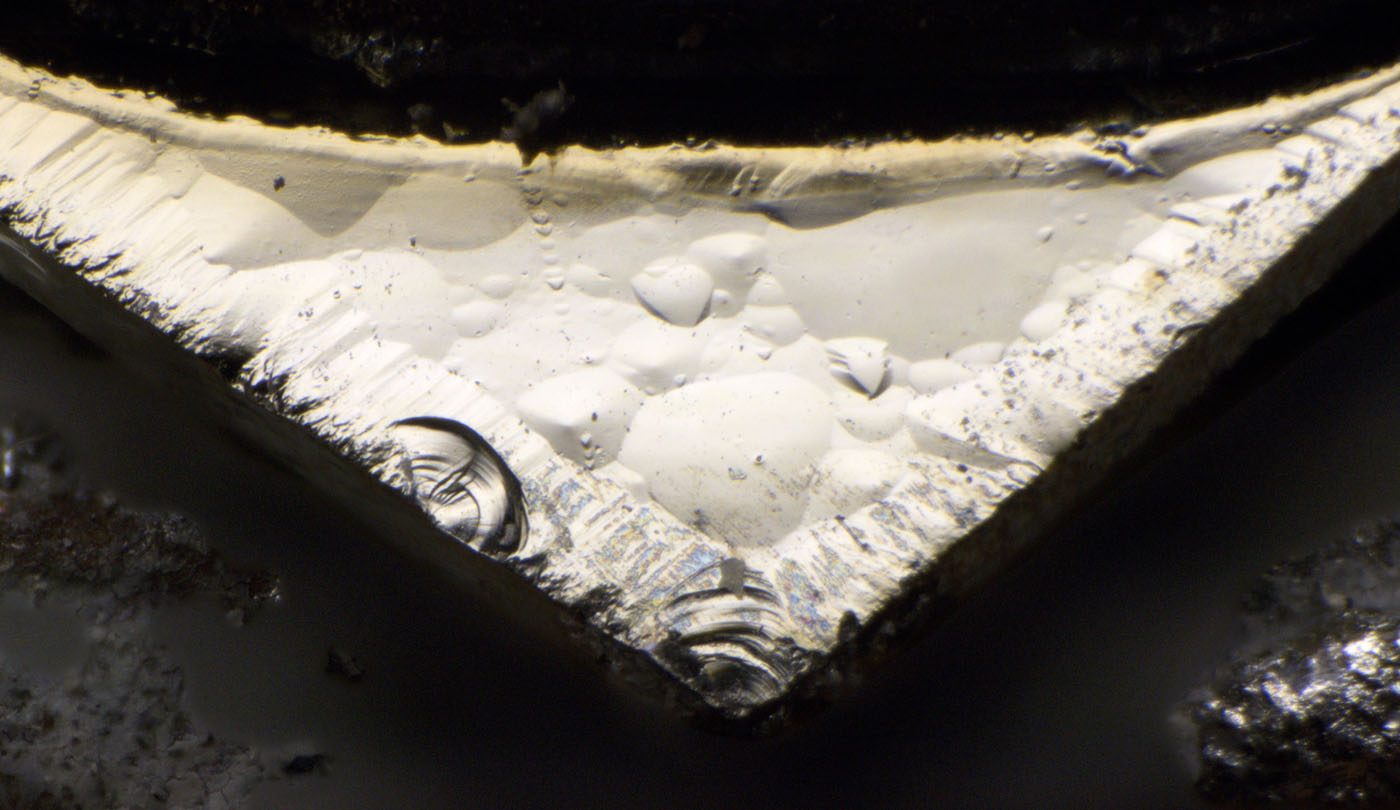

The transistor does not lie completely flat on the socket of the base plate. This allows a better view of the collector area. The alloy material, which covers a larger area on the collector than on the emitter, is clearly visible. Very little solder appears to have been used for the collector connection. With such a small contact area, it is difficult to dissipate the transistor's power loss. In order to obtain high-quality transistors, this process would definitely need some optimization.

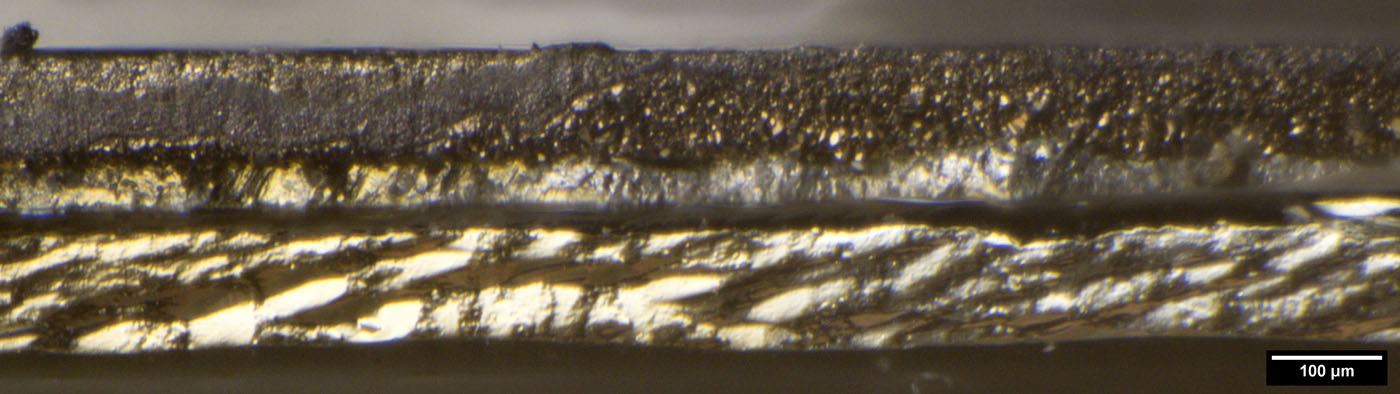

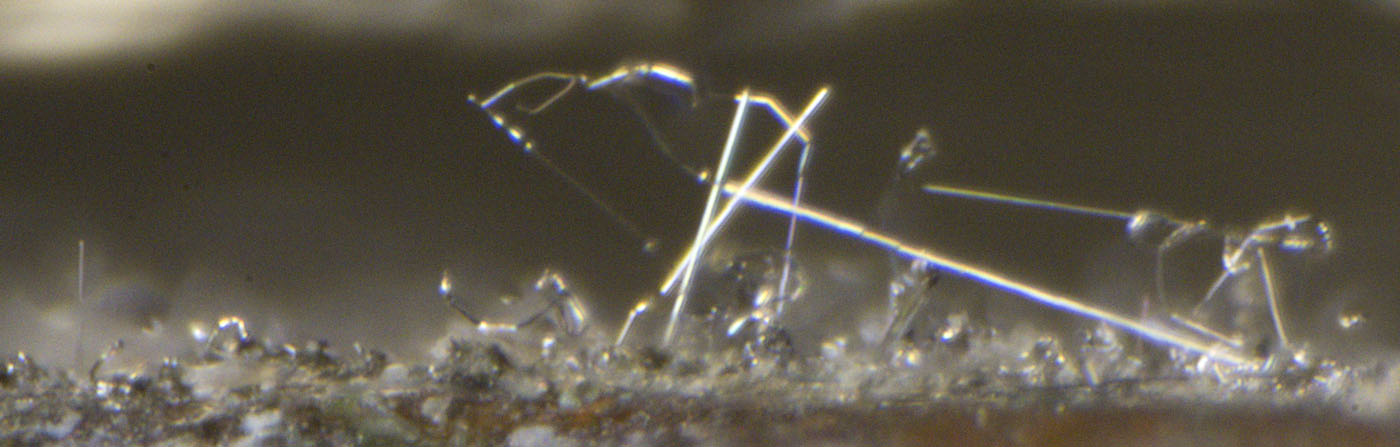

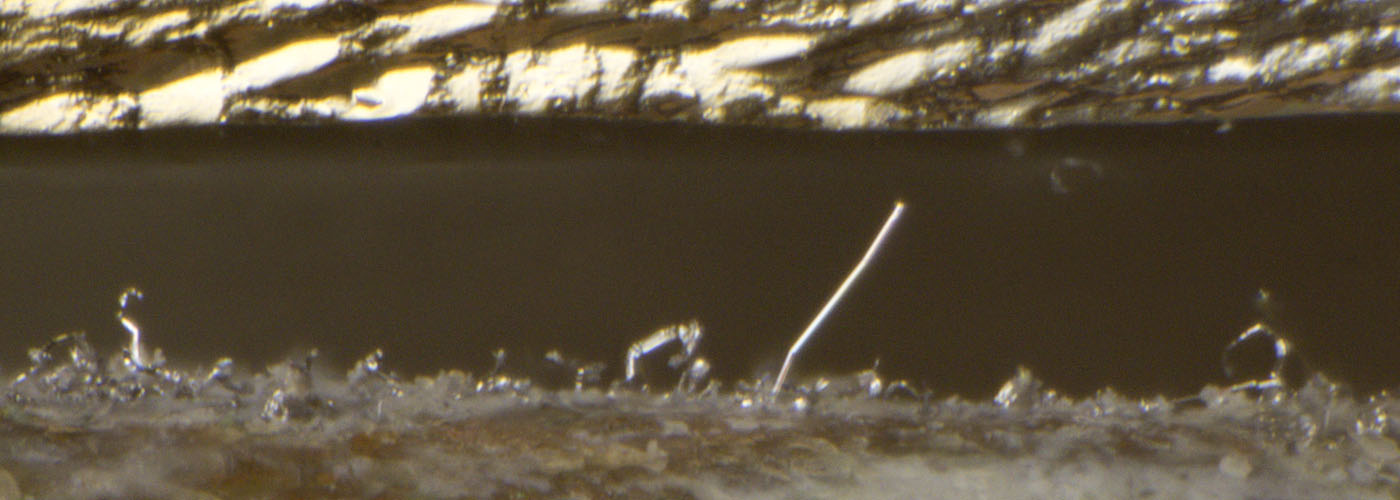

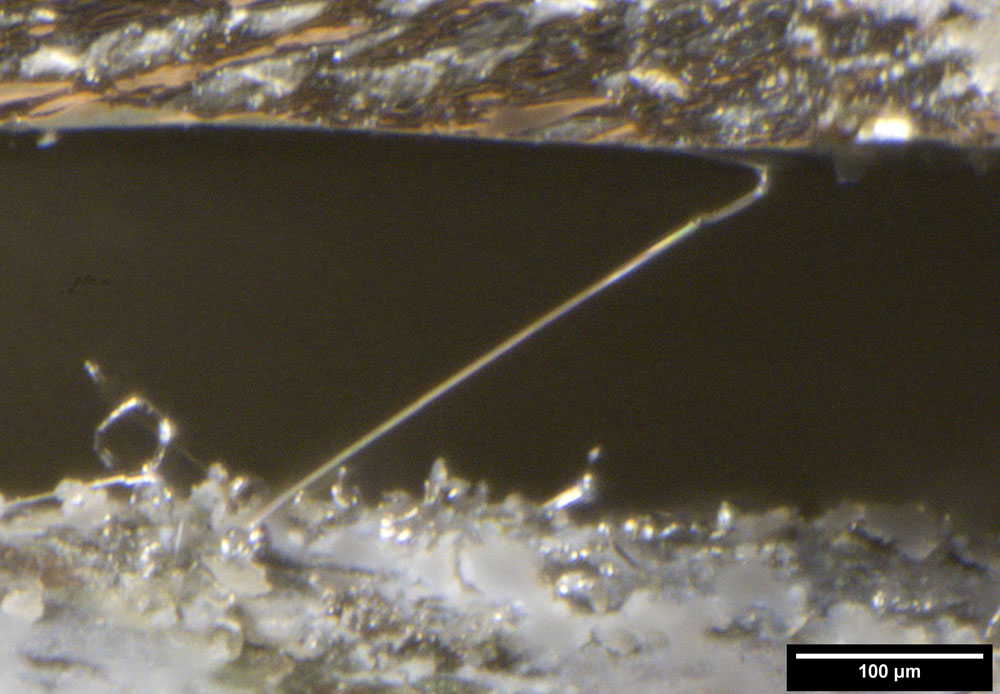

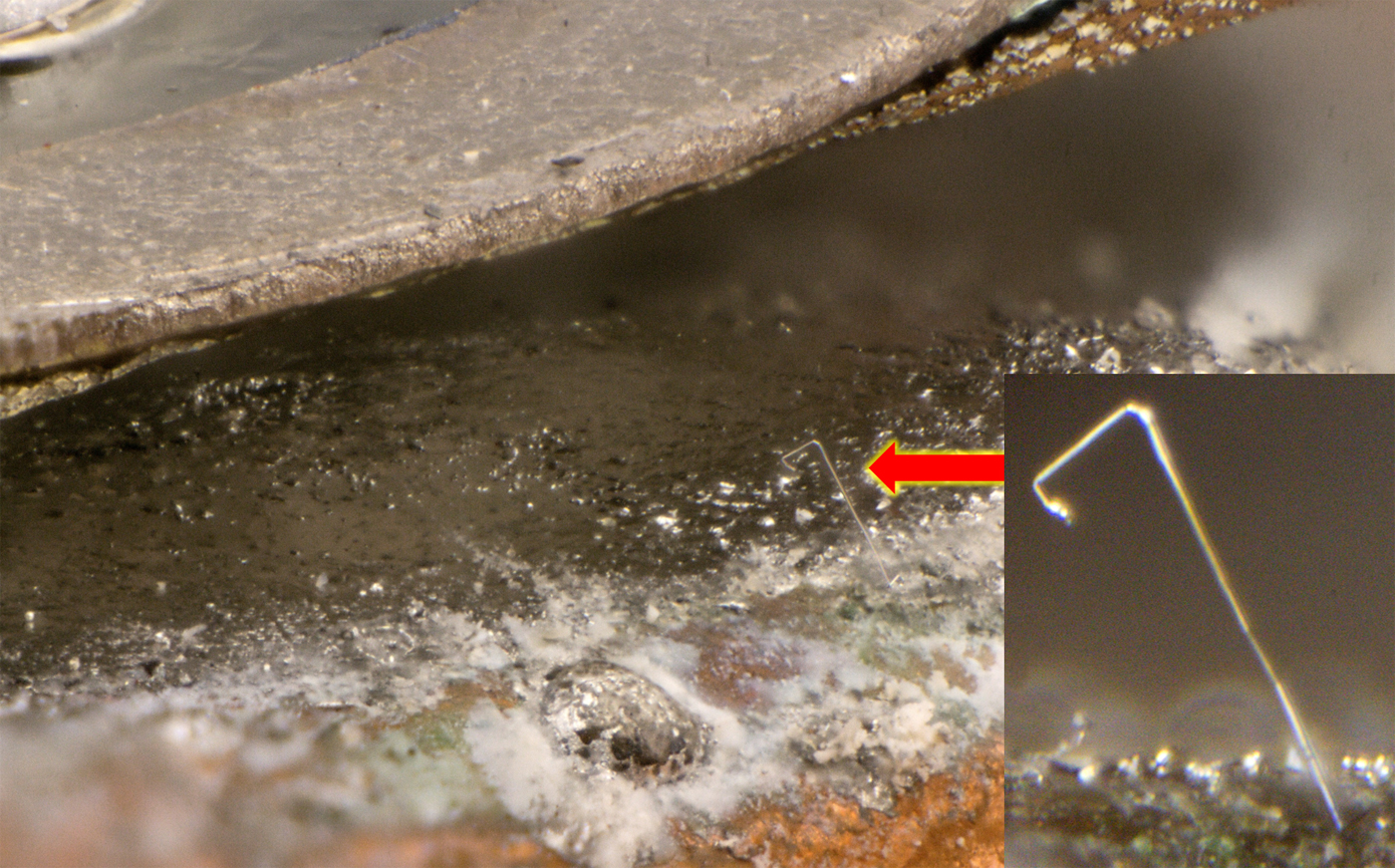

On closer inspection, you can see that so-called whiskers that have formed on the base. This is usually tin, which forms such crystal structures over time under certain circumstances. These whiskers can cause short circuits.

The diameter of the whiskers is just 5µm. There appears to be a complete connection between collector and base.

Some of the images also show small dendrites, as were found much more extensively in GD241 (

https://www.richis-lab.de/BipolarA12.htm).

The overview image shows the proportions once again. It could be that the whisker had caused a short circuit, which then was melted by a current flow. This would explain the thickening at the end of the whisker.

https://www.richis-lab.de/BipolarA48.htm