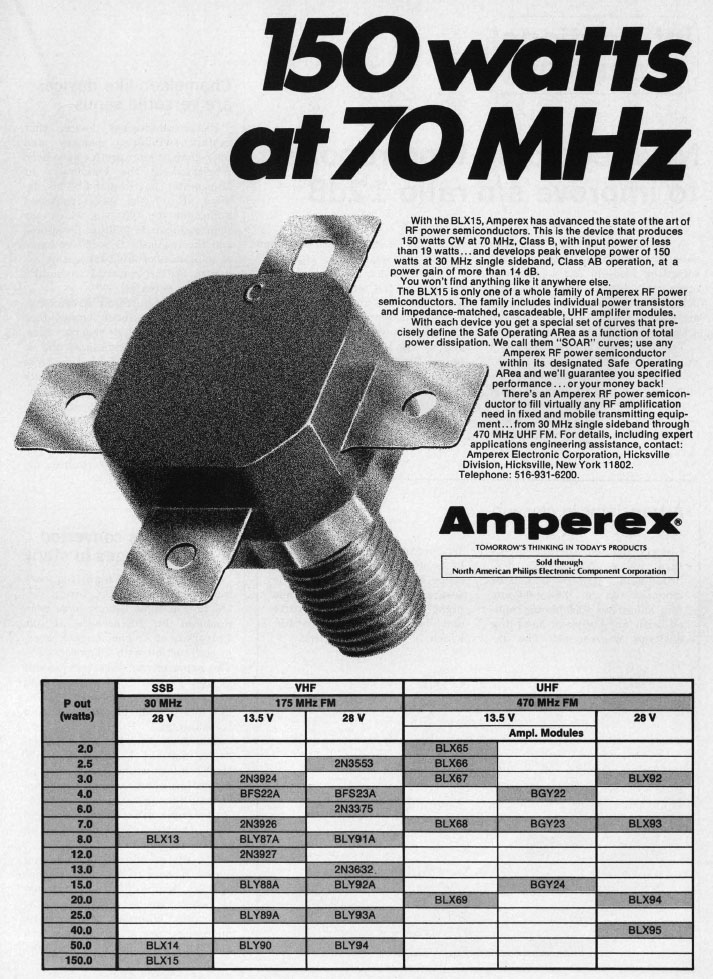

The Philips BLX15 is a RF power transistor in a SOT-55/3 package. In North America, it was distributed by Amperex, which belonged to Philips. The advertisement above is from Electronic Design 18 magazine from September 1973 and shows which transistors are optimised for which power and frequency classes. The BLX15 is the most powerful transistor in the 30 MHz frequency range.

The blocking voltage of the BLX15 is specified as 53V. The large gap to the maximum collector-base voltage is striking, it is specified as 110V. The datasheet allows a continuous collector current of 6,5A and a peak current of 20A. The cut-off frequency is 275MHz. The housing can continuously dissipate up to 195W power loss.

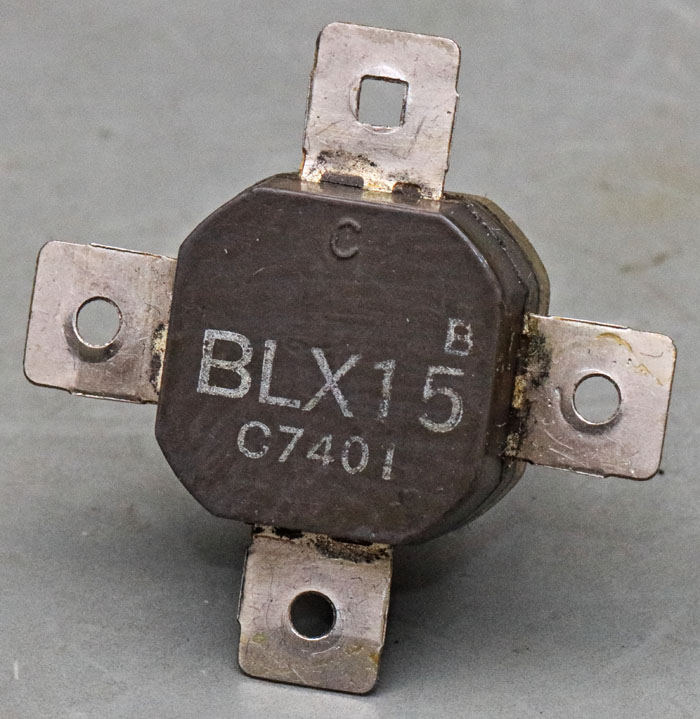

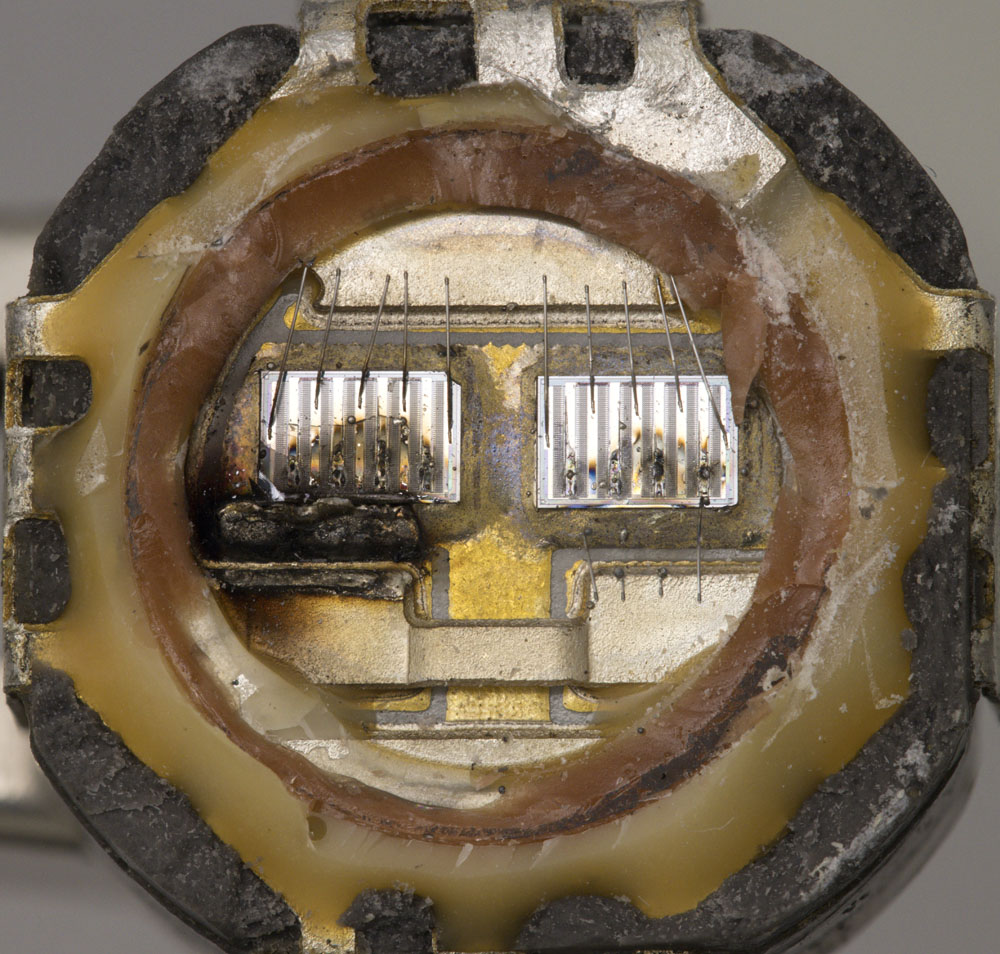

The BLX15 has four large contacts. The collector contact has a rectangular opening and is labelled with a C on the package. The emitter potential is led out to the right and left. The base potential is applied to the lower contact.

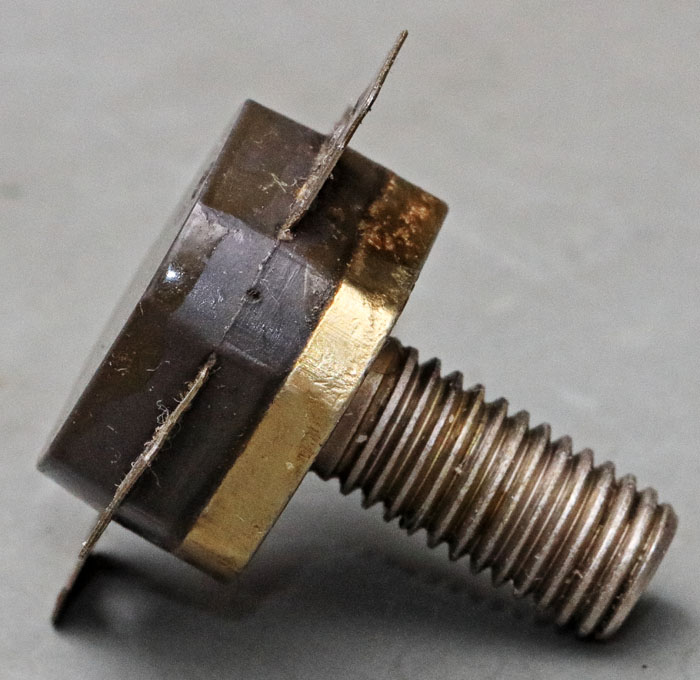

The transistor can be screwed into a heatsink with a thread. The thread merges into a thick metal plate. The upper part of the housing consists of two plastic elements, between which the connections are led out.

The upper plastic element can be broken off. Underneath is a metal cover that is glued to the package. This bond protects the semiconductor from the environment. The plastic housing itself is obviously not sufficiently sealed.

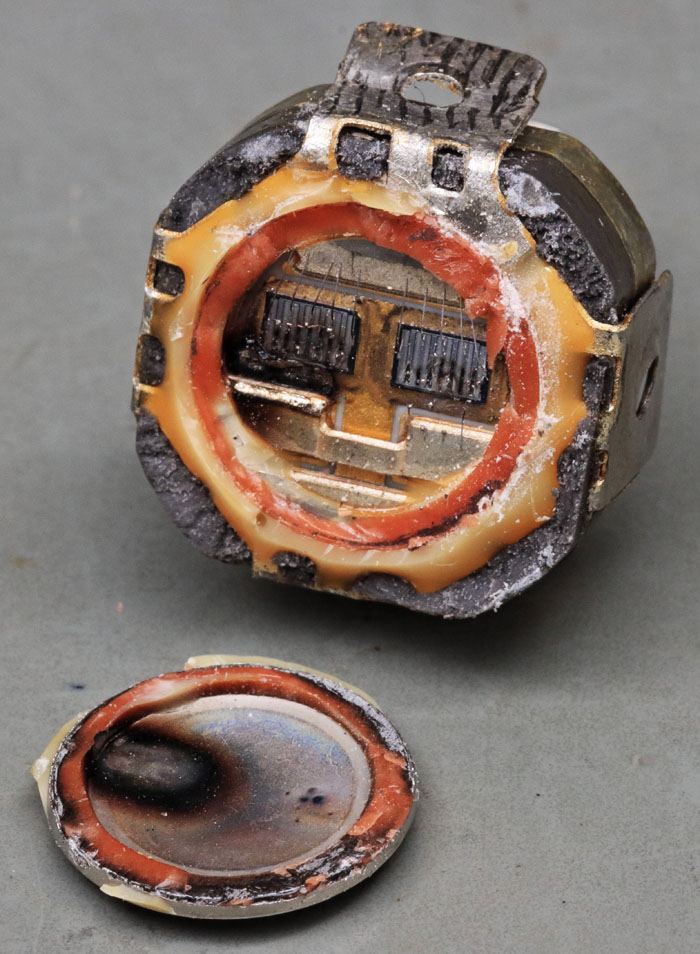

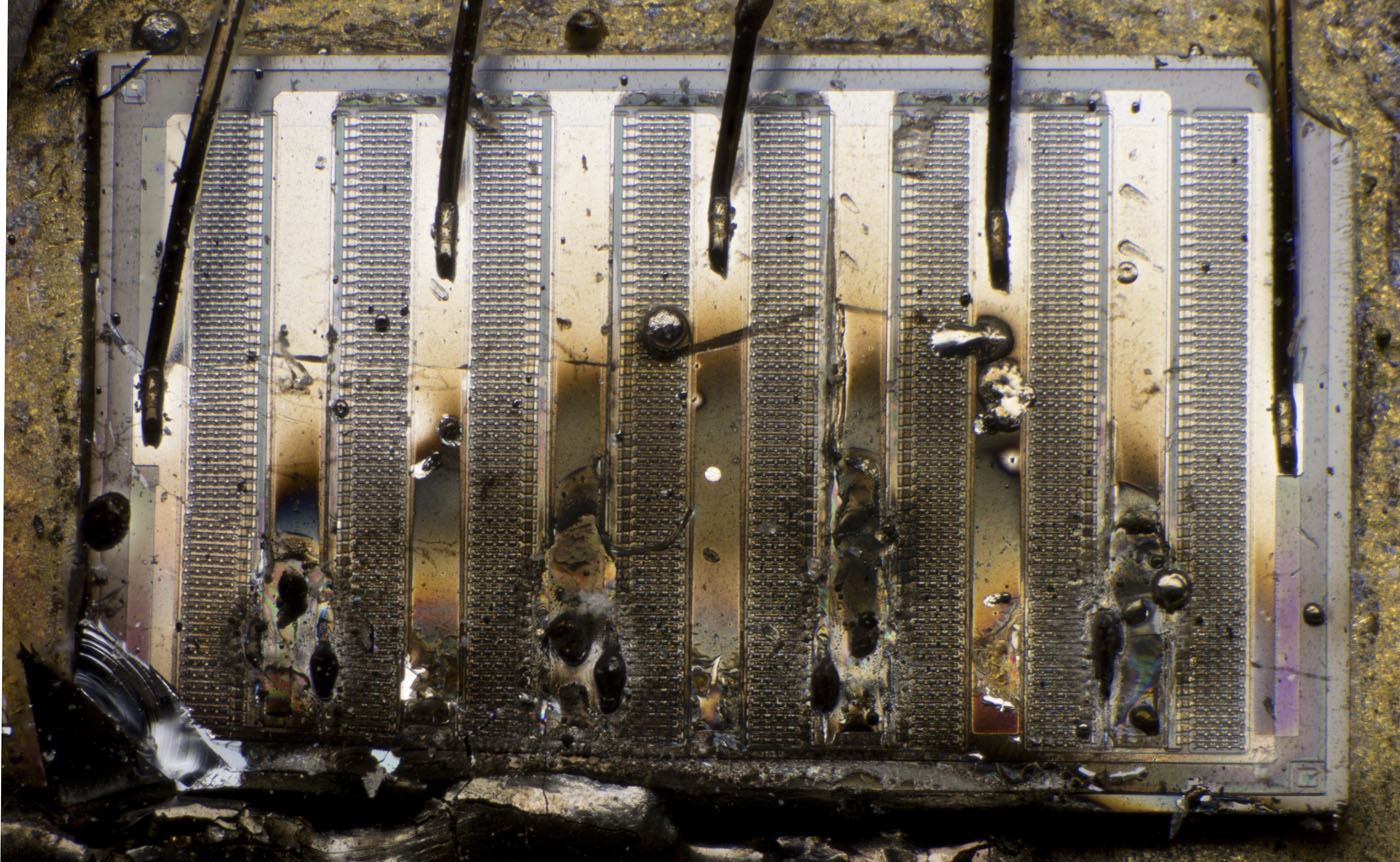

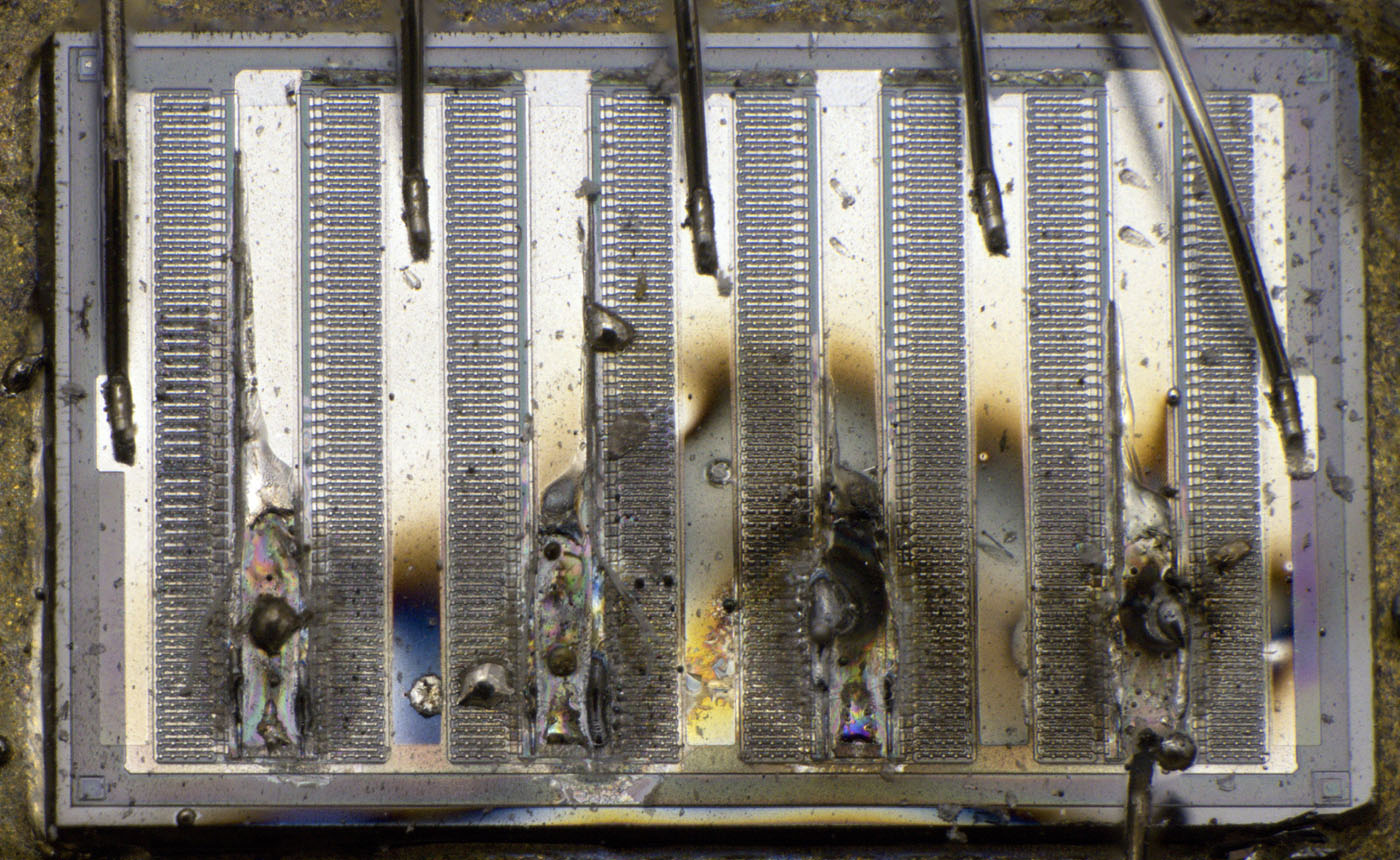

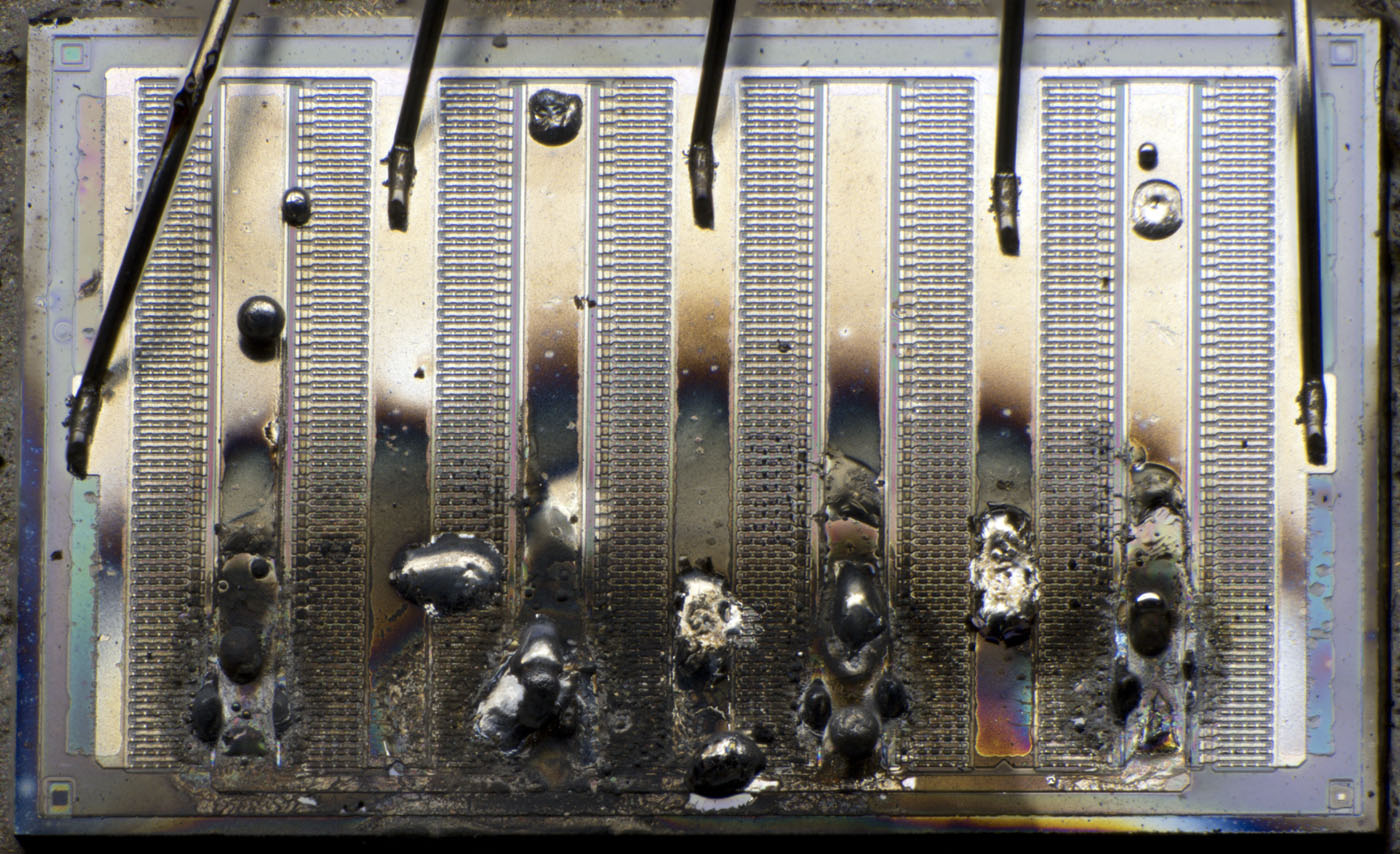

The cover can be removed from the housing with a knife. The transistor was declared defective. The damage is already obvious here. The left side of the cover and the corresponding area in the housing are heavily blackened. But there is also clear damage on the right-hand side.

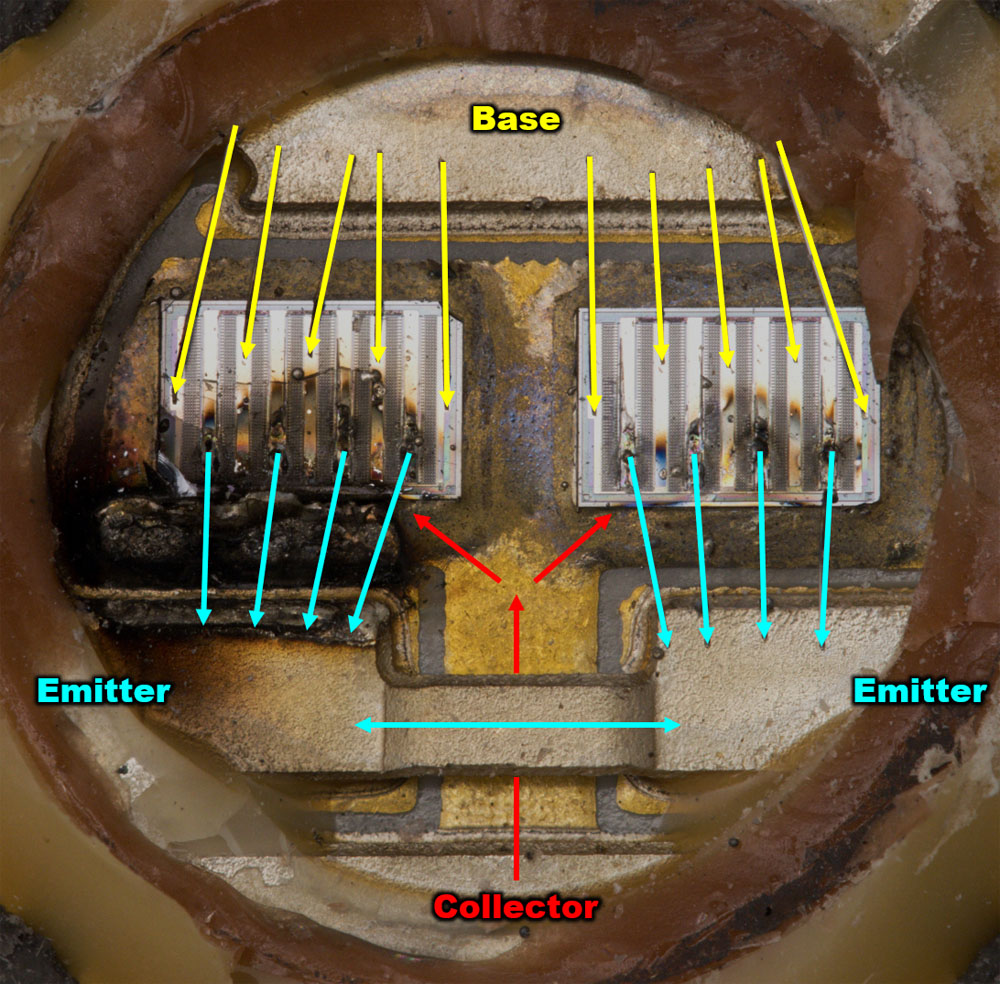

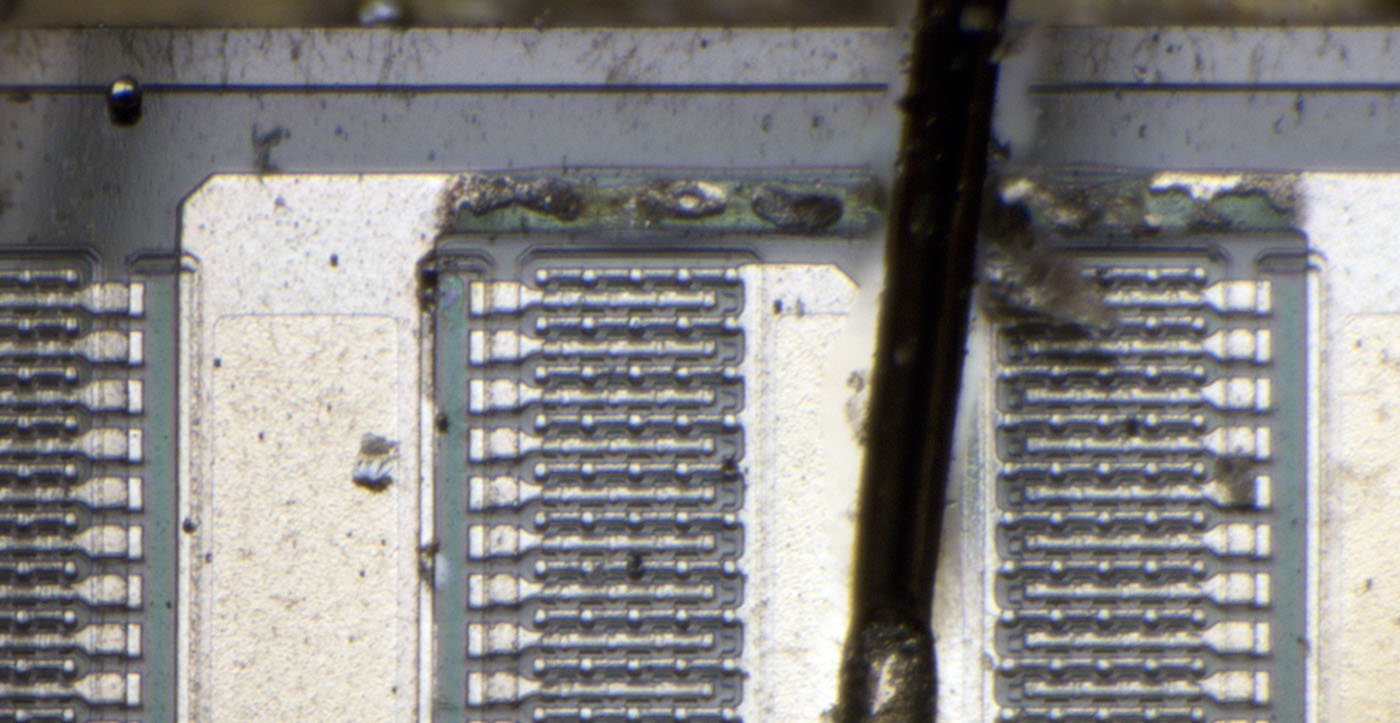

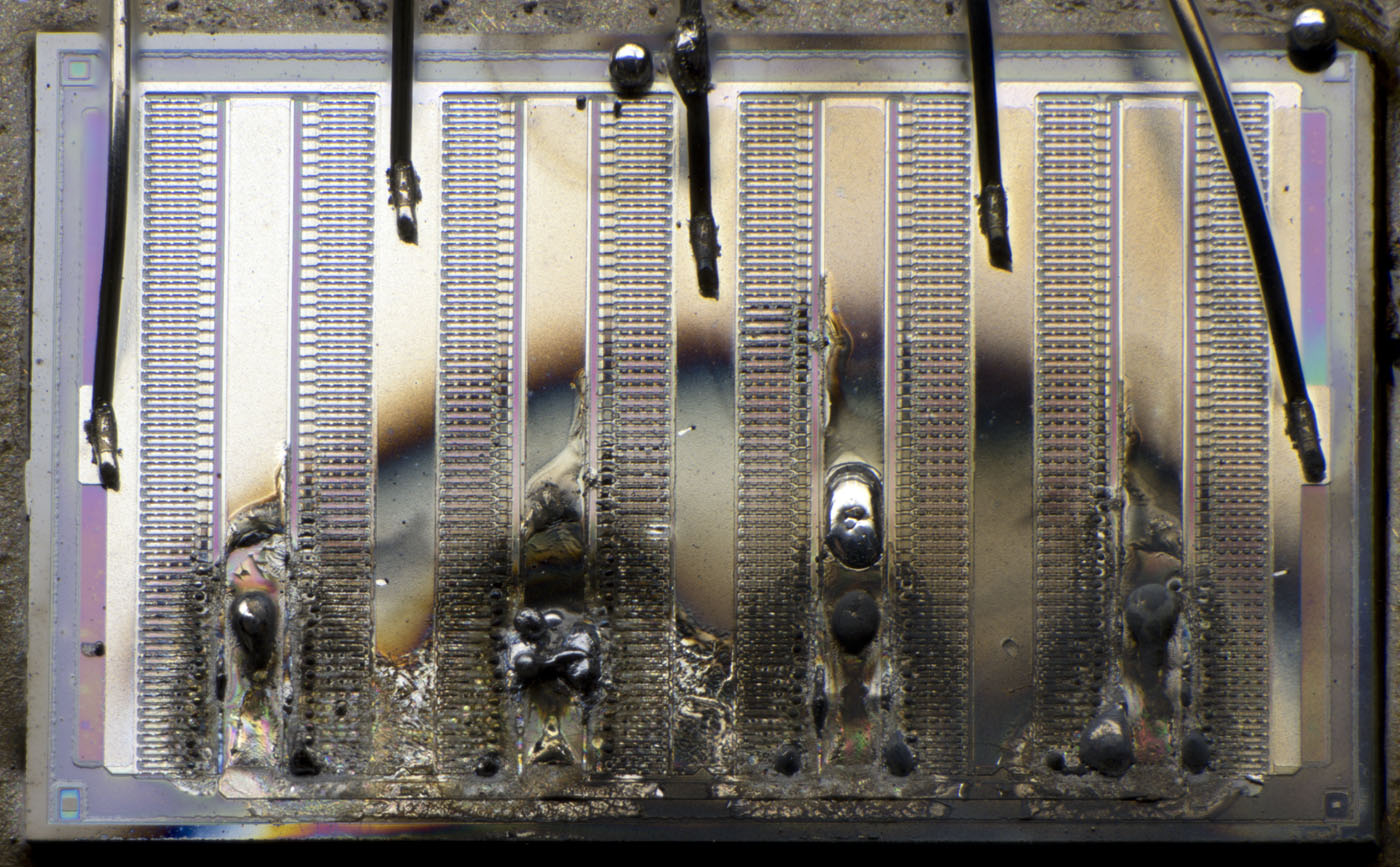

With a little more magnification, the structure of the BLX15 becomes clearly recognisable.

From below, the collector potential is fed to the transistors and led through the substrate into their active area. A metal bracket connects the emitter potentials supplied from the left and right. Four bondwires are available per transistor for the emitter current. The base current, which arrives from above, is even transmitted with five bondwires each.

The transistors are located on a ceramic carrier. This means that the BLX15 can be screwed into a heat sink without additional insulation. However, the ceramic slightly impairs heat conduction. It is remarkable that the datasheet nevertheless specifies a continuous power dissipation of 195W.

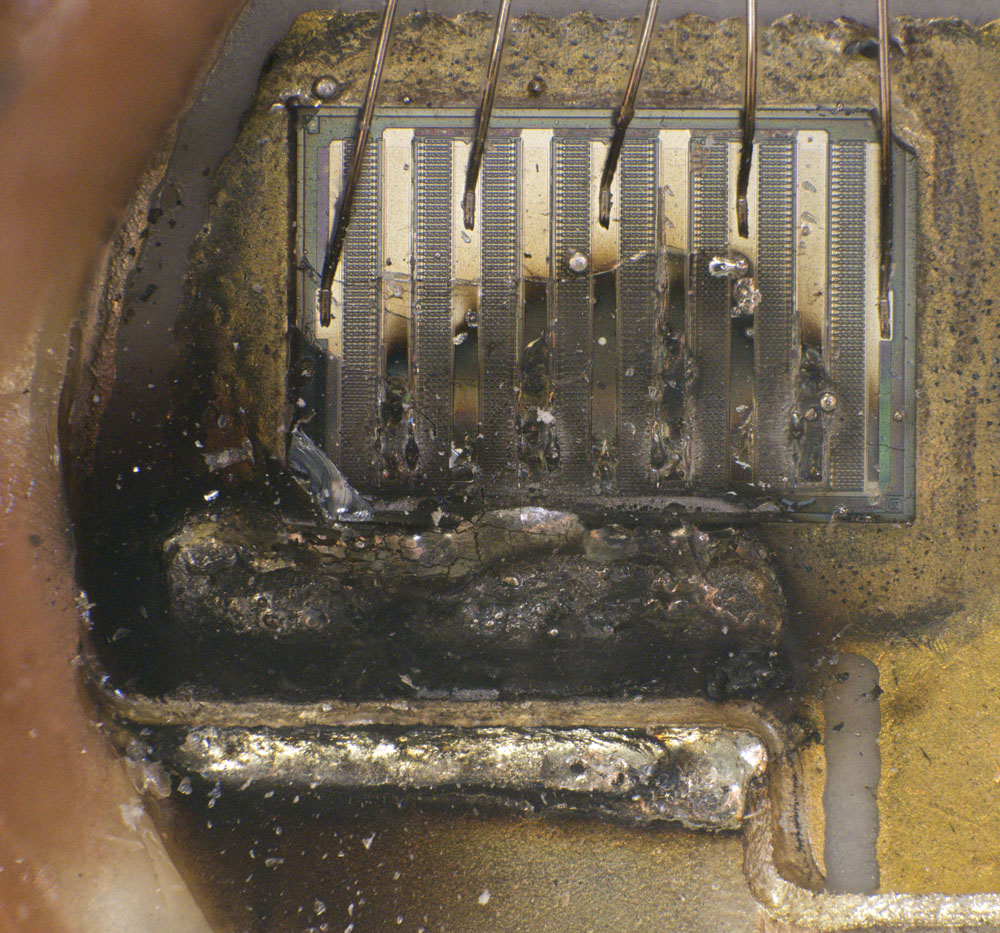

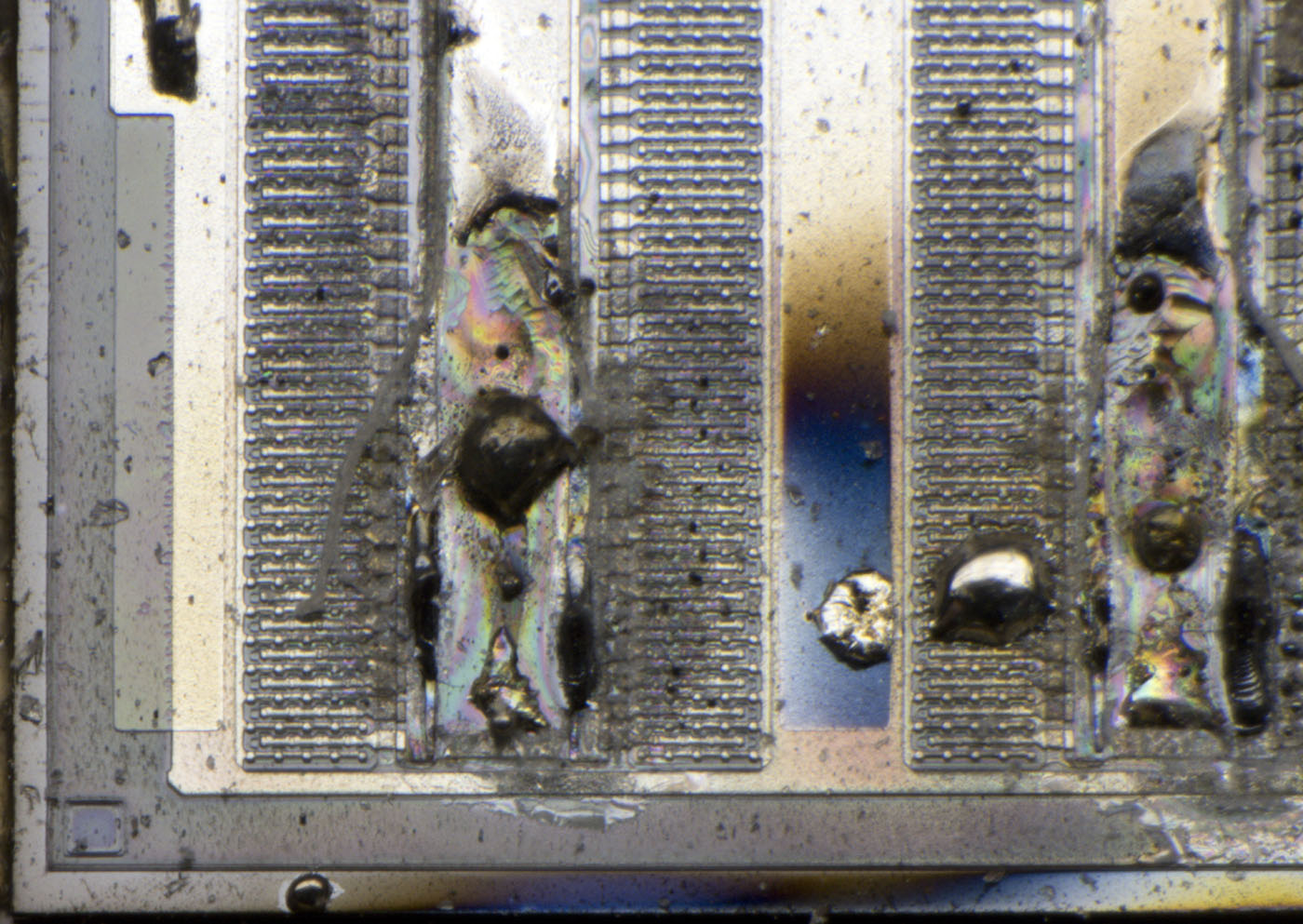

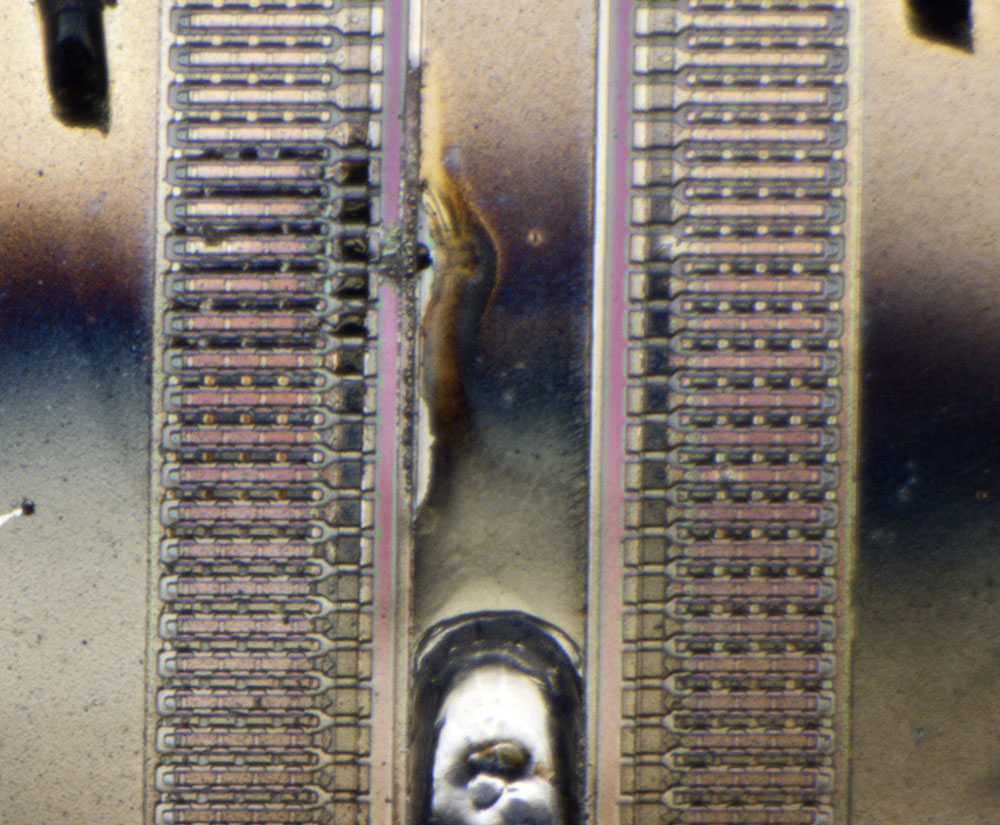

The bondwires on the emitter side of the left die have completely melted. An arc must have been burning for some time, as the edge of the metal rail also was melted considerably.

The insulation area of the ceramic is blackened over a large area. Metal has accumulated in front of the die. As the bondwires do not have that much volume, it must be material from the emitter bud bar.

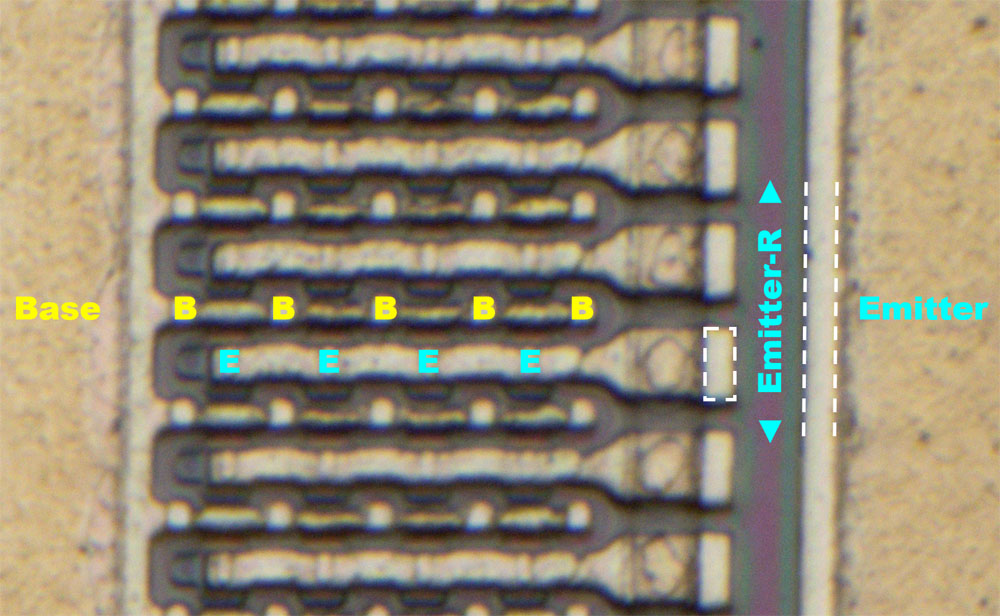

The energy input into the die was so high that the silicon broke in several areas. Nevertheless, the structure of the transistor can still be recognised. There are eight columns, each of which is grouped into pairs. The base current is supplied from one side of each column and the emitter current is dissipated on the other side.

Obviously, there were high equalising currents between the gaps. The metal layer is completely destroyed in the upper area where it connected the gaps.

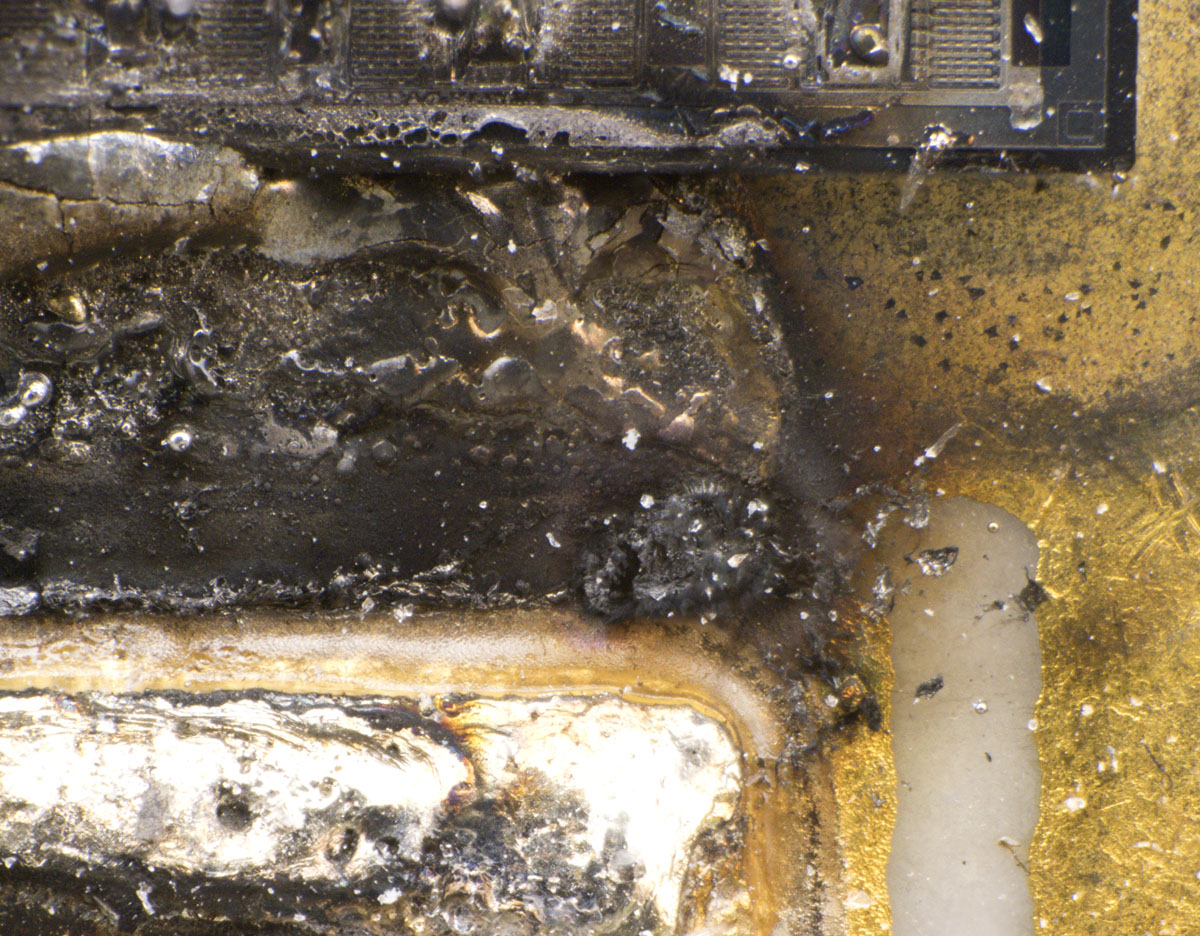

Each of the eight columns contains 52 rows, each with four emitter contacts. It appears to be an overlay transistor, as described in more detail in the 2N3553 (

https://www.richis-lab.de/Bipolar22.htm). On the right, all rows are connected to a common resistor strip, which then leads to the emitter potential. The resistor strip ensures symmetrical current distribution across the rows.

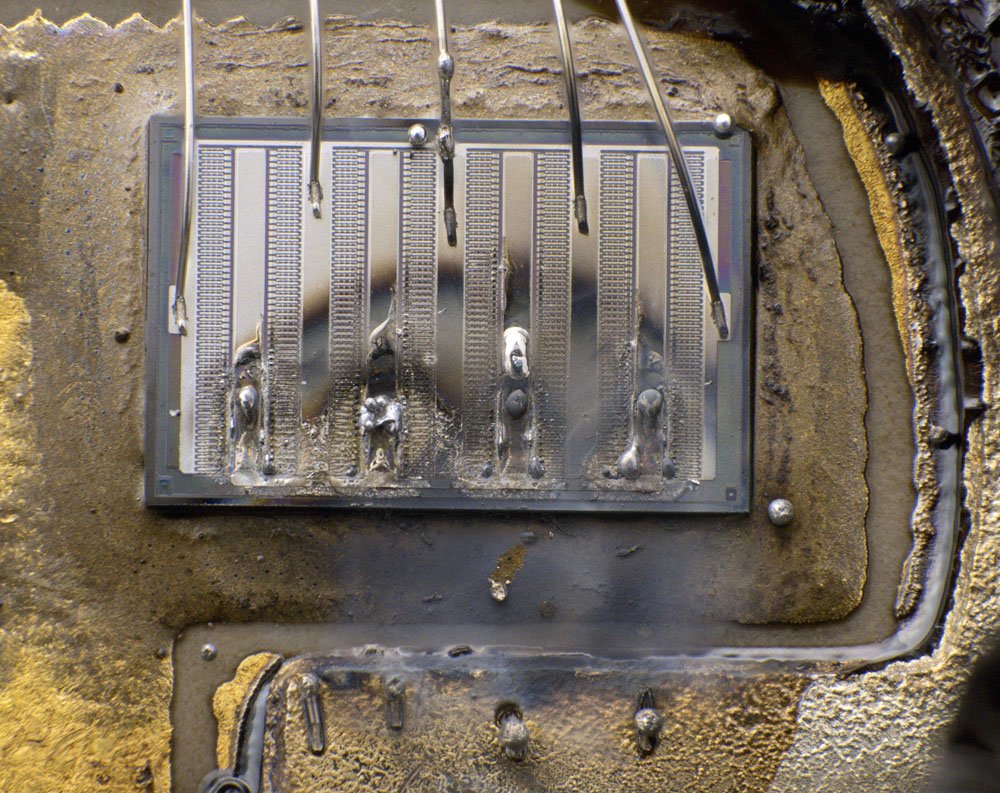

The right-hand side of the BLX15 is less badly damaged. All four bondwires are melted but still recognisable. The die is partially melted and discoloured in the area where the bondwires were attached, but the area around the transistor is still intact.

Here, too, all the connecting elements on the upper edge have been destroyed.

Where the bondwires made contact with the emitter potential, the metal layer melted over a large area.

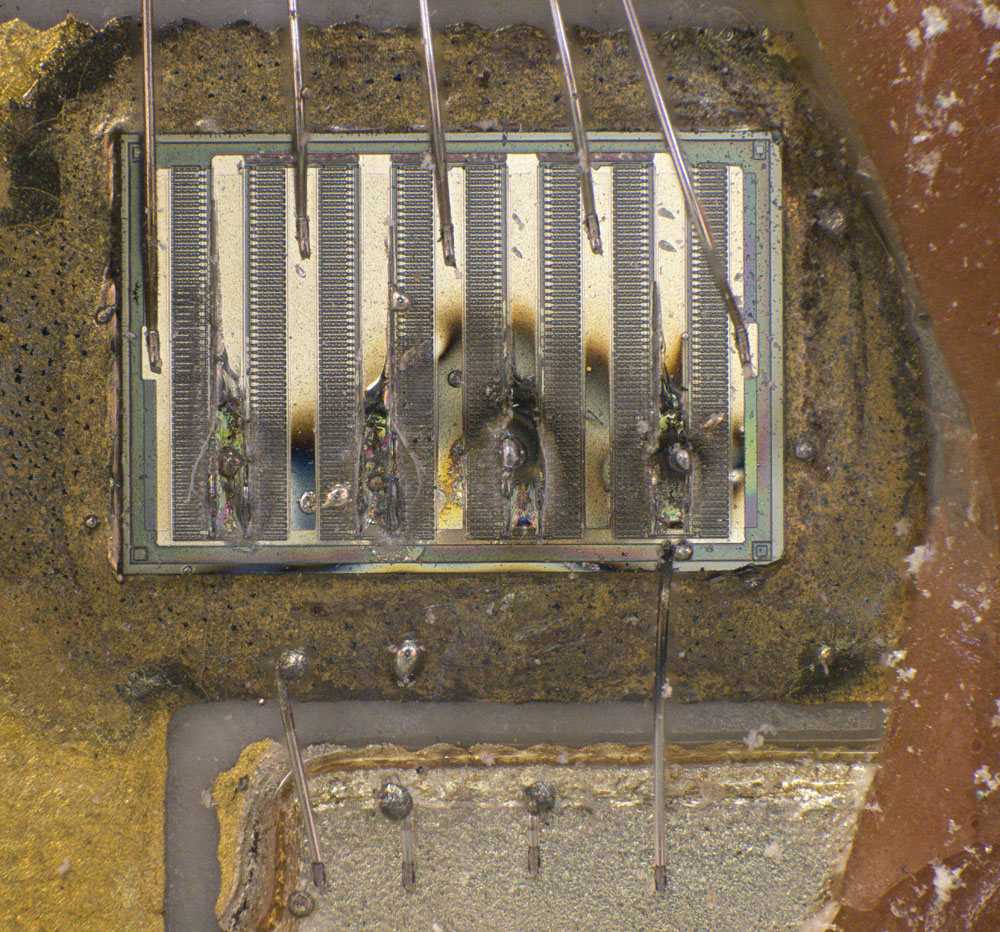

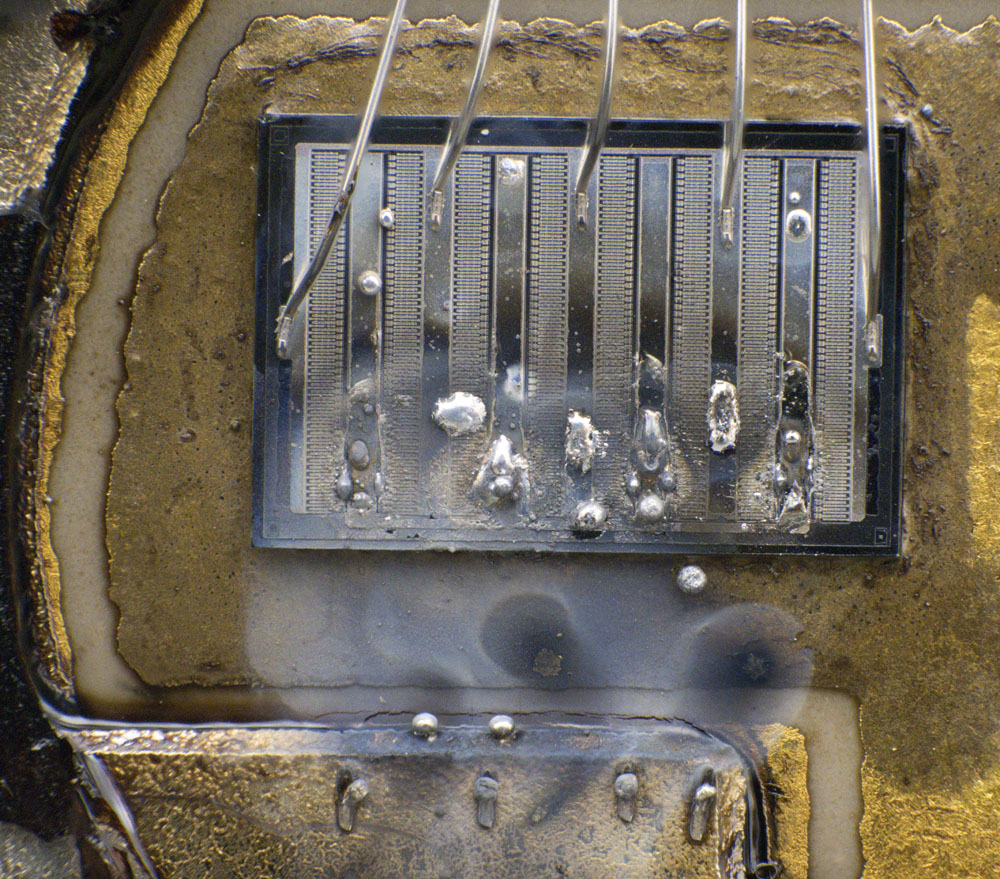

Here you can see a second defective BLX15. The package and labelling corresponded to the BLX15 above. The metal cover of this transistor was thermally opened.

Here, too, both transistors are destroyed. The degree of destruction is slightly less severe. The emitter bondwires of both transistors are completely melted.

The transistors are constructed in exactly the same way as in the first BLX15. Here, the connections between the emitter areas are still intact.

There is an artefact on the right-hand transistor slightly away from the bondwires that could be the starting point of the destruction. The emitter resistor between two emitter lines appears to have been destroyed locally, regardless of the surroundings. The collector line for the emitter current and some of the emitter lines have also melted in this area. Of course with such massive destruction, it is not possible to say for sure whether this was really the starting point of the failure.

https://www.richis-lab.de/BipolarA51.htm