If you set it to 4100 and no iron is still there, check the ambient temperature.

KSGERs usualy have the ambient sensor in the the handle.

If unconnected, the ambient temperature reading will be below -60ºC. That also triggers the detection.

With the default 200mS PWM, the tip only gets updated 5 times per second. Setting a high EMA/DEMA factor will make the filtering response very slow.

Leave it in AVG by default. Set the temperature and play with settings until there are no spikes or anything weird.

Then you might try the other filters.

EMA causes delay at the filter output, and will cause PID overshoot.

If done correctly this can be beneficial, to compensate the tip thermal mass (Heat doesn't travel instantly from the heater to the tip),making it to heat faster without real overshoot.

However, when the tip gets cold, it also causes delay so the PID will not react so fast.

DEMA also has delay, but will react faster to the changes.

It will stop the PID faster when it reaches the temp, but also when the tip loses heat.

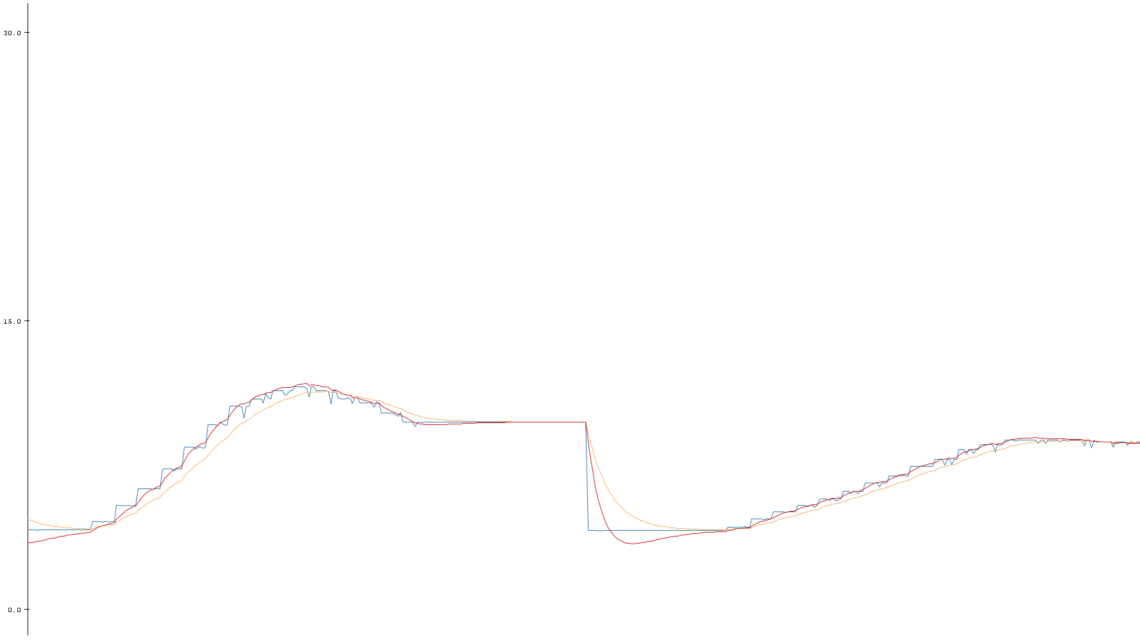

Check this picture (Blue line: original signal, orange line: regular EMA, red line: DEMA.):

As you see, this can affect the PID a lot. Must be carefully tested, it can cause serious oscillations.

I wouldn't use it with a factor higher than 2 by default.

Also, did you play with the ADC delay? Setting it too low will cause a lot of trouble, false readings and such.

If you lower too much, the ADC will be reading the voltage spikes after turning off the heater.

By default is set to 200mS PWM, 20mS delay, it was the most stable, safe and efficient.

Builds updated!

No more random bootloops when the settings version changes.

Calibration should be doing well now. Also the ADC values are shown when successful.

Added more checks to ensure the calibration values never get higher than the ADC range, otherwise set the calibration failed.

Hopefully this was the last issue with red hot tips. The only red hot things I like are the chili peppers