Time for the last episode: Mains Filter & Fan

The unit went down on April 27th for the remaining replacements (

list of parts updated & finalized).

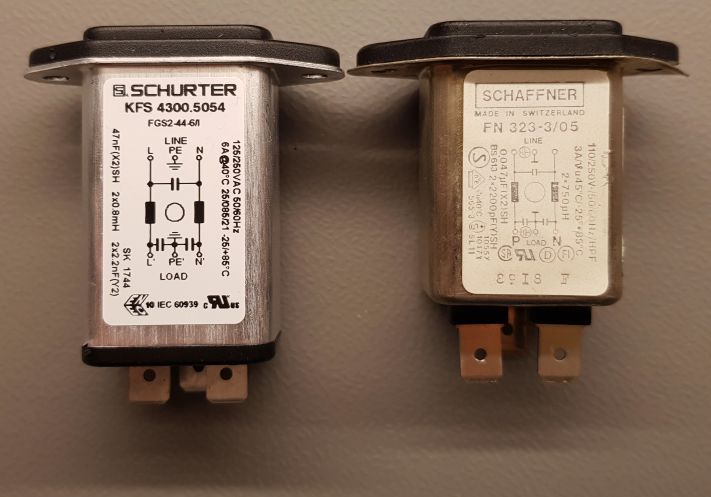

Drilling the rivets of the mains filter was a bit harder than thought -

my HP3457A did not struggle that much.

After lots of chips and a bit of brute force it was released from its former job and replaced with new Schurter type.

The new one is a bit longer, but no problem to fit it in its place.

The RIFA MP Y-Caps on board were removed last time and now refitted with WIMA MKP (

see attached picture).

Interestingly the time did not improve on size of this types (compared to electrolytic ones), the new ones are thicker and higher - this gives confidence, that they will last long after me.

For the problem with the new fan and its bigger screw holes a simple solution has been elaborated.

Fill them with epoxy (e.g. J-B Weld) and after curing drill them to size of holes from original fan.

(the spacings are identical, corrected statement in former post - I obviously squinted as

the picture already showed this)

Although J-B Weld ist tought to be the strongest epoxy, it did not stick enough on cleaned, but unprepared holes when screwing it

After filing the inside of the holes to roughen them a bit, the procedure was repeated with success.

The new fan is not significantly quieter, but the annoying metal scratching sound has gone now.

I decided to fix the bend cap - just to be safe - but it defended to go into its intended form.

Heating multiple times to finally ~200°C and bending it with quite some force to its desired shape, it bended back again after cooling down

Sanding with 600 grid finally it gave up and went flat (

picture of assembly of both caps and ref-board attached).

Before:

After:

Last thing was to replace overlooked 22uF yellow cap - just a mere formality (

see attached picture).

Hopefully all the sweat comes to a happy end and unit is now in good condition.

The ADC drift actually settled to ~0.035 ppm/day for 3 weeks now, before it stayed at ~0.05ppm/day for two months.

The "noise" generated by acal dc is around 0.1ppm-pp according to cal 72, from this point an acal on my unit would be sufficient every 3 days.

With ~0.33ppm TC of ADC this becomes the mayor drive to perform an acal - at least for every °C change (

see attached picture of last 3 weeks).

My unit seems to stop drifting during power down, but soon there will be more data to confirm this.

The measured stability before and after final work against external LTZ1000 showed drift in sub-ppm region - fortunately no unpleasant surprises

.

Combined noise/drift (+TC) from unit and external reference are ~0,13 ppm stddev and ~0,5ppm-pp (3 days, 1°C span, 100NPLCs, 7V, acal every hour)

Combined TC maybe ~-0,3ppm/°C, but the external ref is not characterized nor trimmed for TC.

This data is just for reference, this has to be repeated with better setup.

There are a couple of things left for full characterization and to be shure it is in good condition:

-log input noise for the ranges and NPLCs

-check input bias current at different voltages and ranges

-measure TC of whole unit

-calibration

-long term drift

Big thanks goes to the 3458A nuts - especially to TiN and his great articles - with the help of this superb documentation the work was nearly straight forward.