Ok, here it comes:

Only 2 screws later it looks like this:

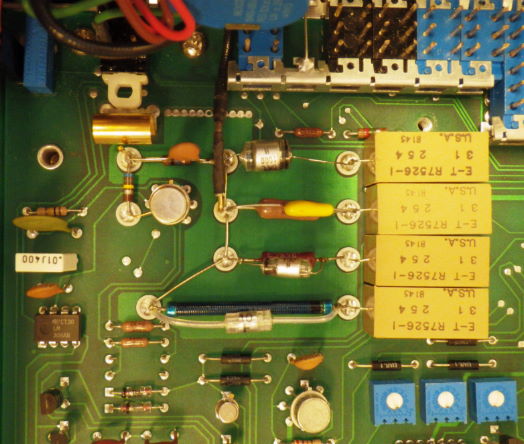

Another 4 screws later it looks like this:

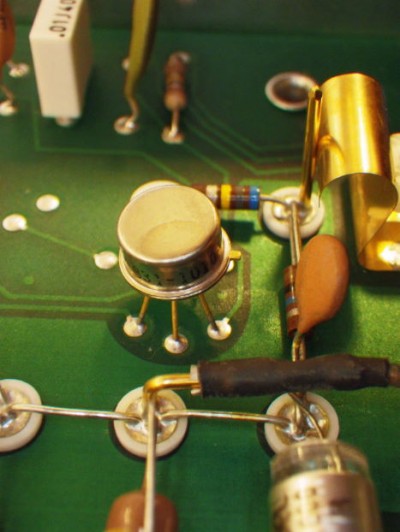

As already suspected/stated by free_electron, the (matched) FETs are in a single package with what I suspect is a custom number - probably it's specially selected devices: MP831-1010-8145 (last four digits might be the date code):

The reference FET is directly connected to the FR4 board, while the electrometer nodes are on ceramic insulators on top of the board. The gold-plated pin and sheet in the background is the zeroing of the input - mechanically mounted on the front-panel switch. The black heat-shrink tubing in the front is around the coax-lead from the input connector. Personally I do not like the carbon composite resistors (I assume that's what they are) in the input section, but these are mostly for overvoltage protection of the input anyway...

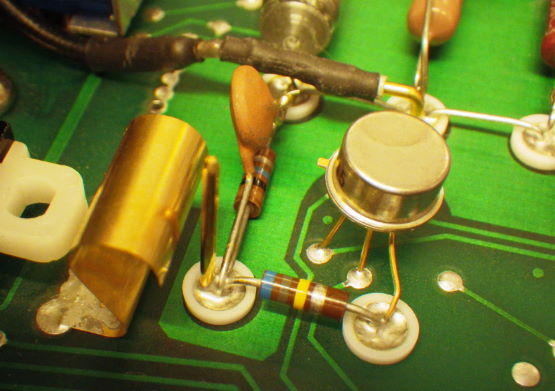

Another view of the input stage (this time with un-grounded input):

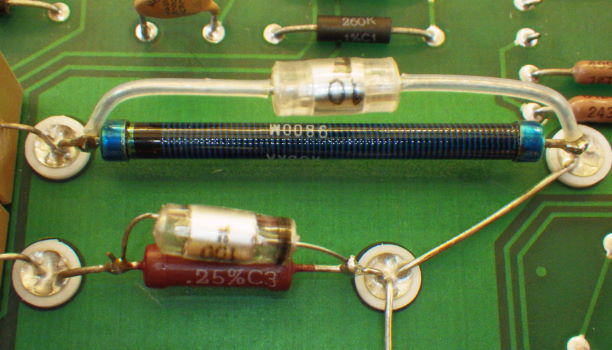

And finally the feedback resistors:

As you can see: no guarding of the resistors' bodies themselves apart from the ground plane underneath and the aluminum cage (removed) above...