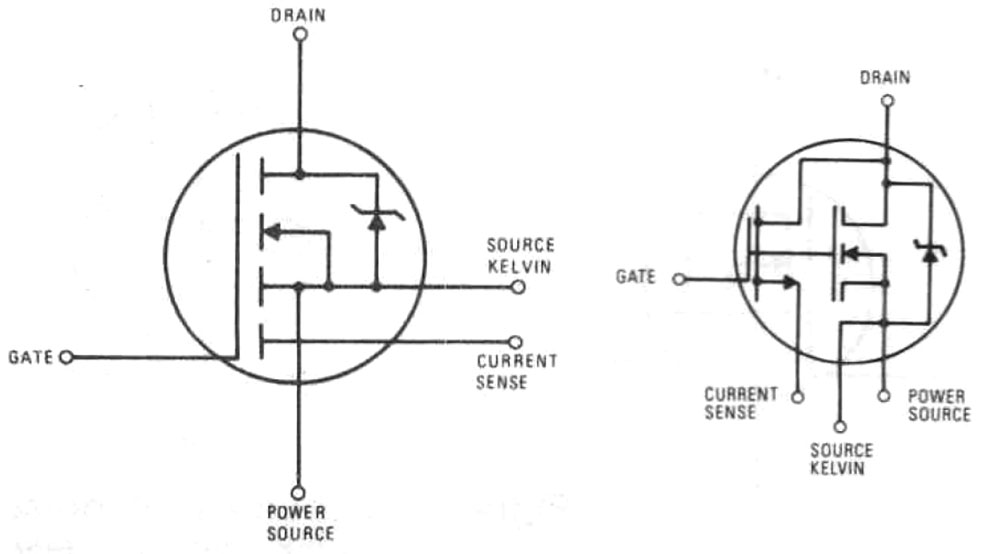

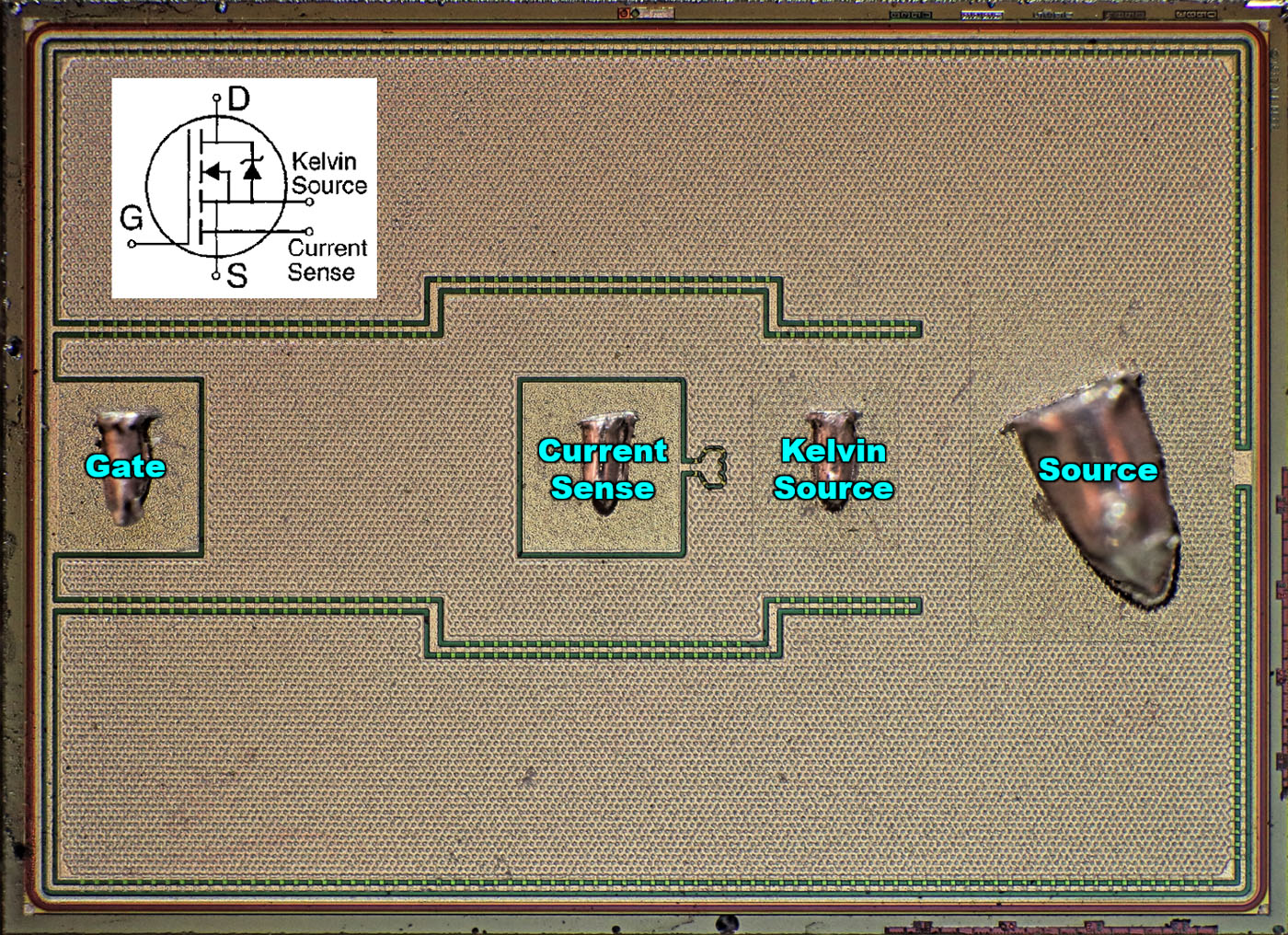

The IRC540 belongs to a group of special MOSFETs that International Rectifier had in its programme under the name HEXSense. The circuit diagrams above are taken from International Rectifier Application Note 959B. HEXSense MOSFETs offer a special path that facilitates current measurement. The symbol on the left is common. However, the mode of operation is less clear there. The right-hand symbol is easier to understand. You can see that there are two MOSFETs connected in parallel. The symbol of the left-hand MOSFET is somewhat misleading. It has exactly the same structures as the right-hand MOSFET and is even located within its structures. However, the left-hand MOSFET is significantly smaller and therefore only conducts a small proportion of the total current via the Current Sense pin. The small current is much easier to measure than the large load current. The ratio of the areas defines the ratio of the current distribution, which allows the total current to be determined.

The second additional pin represents a Kelvin connection of the source potential. With power transistors, such a contact is usually used to realise the most ideal control possible. Increasing load currents generate voltage drops at the inductances of the bondwires and the pins of the package. These voltage drops initially reduce the effective gate-source voltage directly at the silicon, which reduces the switching speed. If the Kelvin contact is used for gate control, this is independent of the load current. With HEXSense MOSFETs, the Kelvin contact can also be used for more effective gate control. However, it is also required to realise the most accurate current measurement. The smaller MOSFET should work with the same current paths and resistances as the MOSFET that carries the majority of the load current.

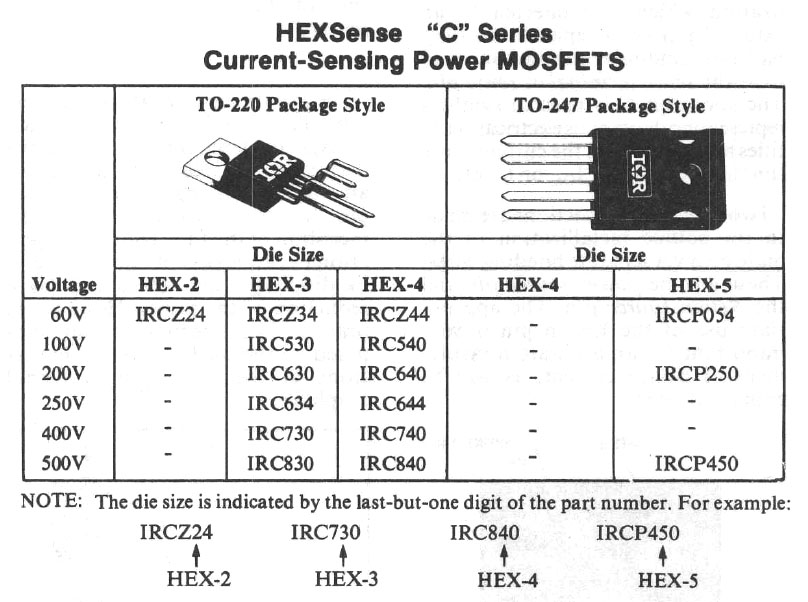

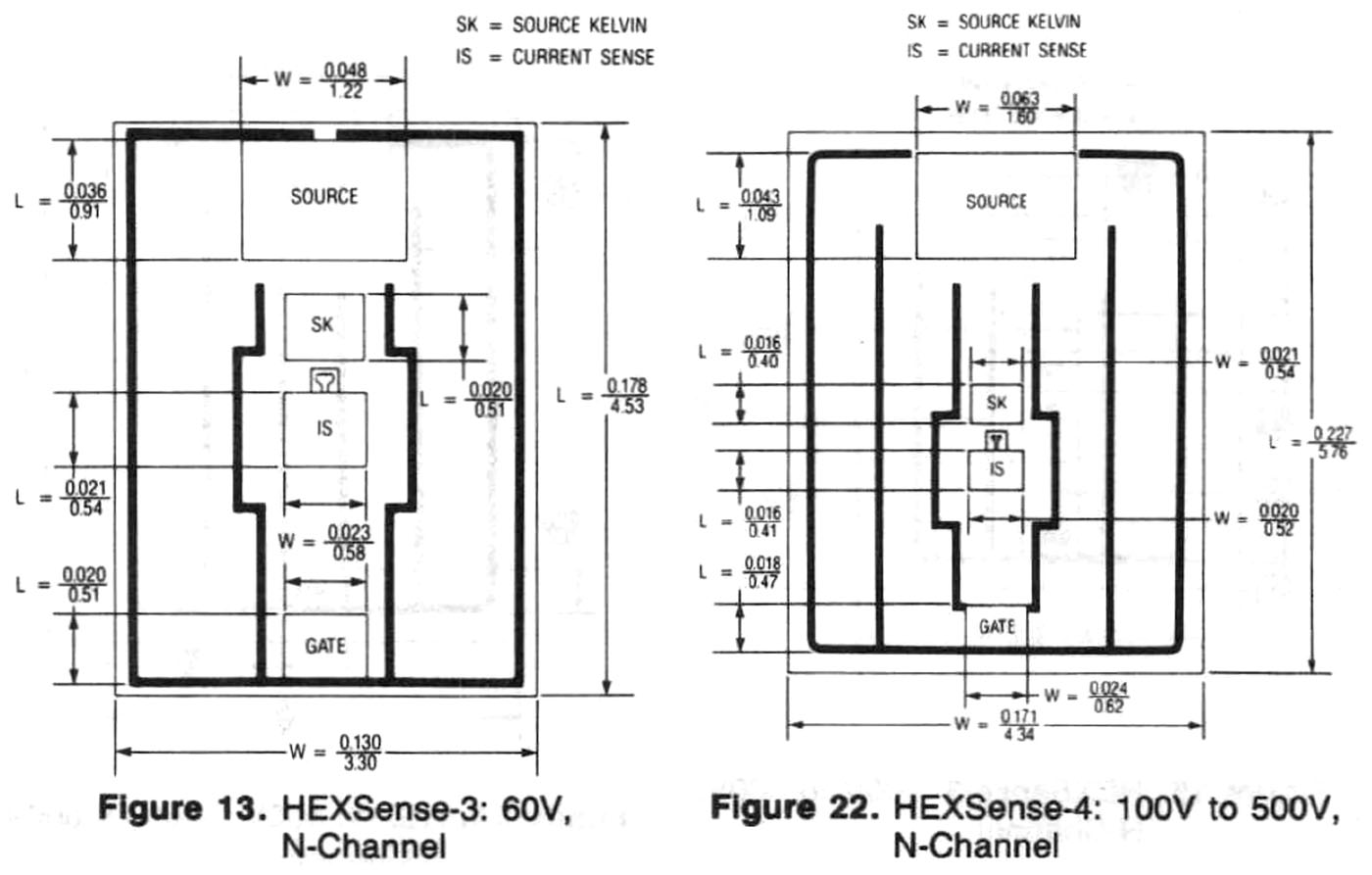

The HEXSense MOSFETs were based on the third generation HEXFET process, which was introduced in 1986 according to the International Rectifier Application Note 959B. This application note lists the different variants of HEXSense MOSFETs. The penultimate number of the designation shows which die size was used. The sizes HEX-2 to HEX-5 were used for the HEXSense MOSFETs. The smaller HEX-1 and HEX-Z variants were also used for the simple MOSFETs.

The IRC540 therefore uses size HEX-4 and has a reverse voltage of 100V. At room temperature, the IRC540 can conduct a drain current of 28A continuously. A short-term current of 110A is permissible. The ratio between load current and sense current is typically 2680:1, with a tolerance of approximately +/-4%. In addition, there is a temperature drift of approximately +/-1%. The typical Rdson is 77mΩ. The package allows a power dissipation of up to 150W.

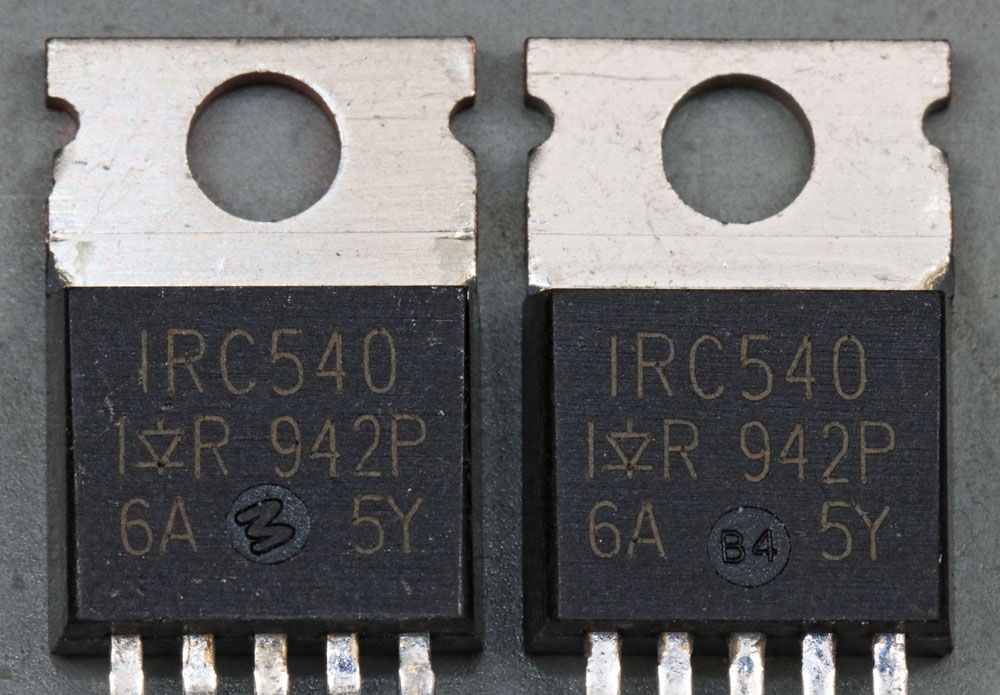

The two IRC540 shown here are from Pollin. They were originally three. The visual appearance let us doubt that they are original parts. The marking says exactly the same. However, the lettering on the right is slightly shifted to the left. The embossed characters are even more striking. Despite the same labelling, a twisted M is depicted on the left, while on the right there are the characters B4.

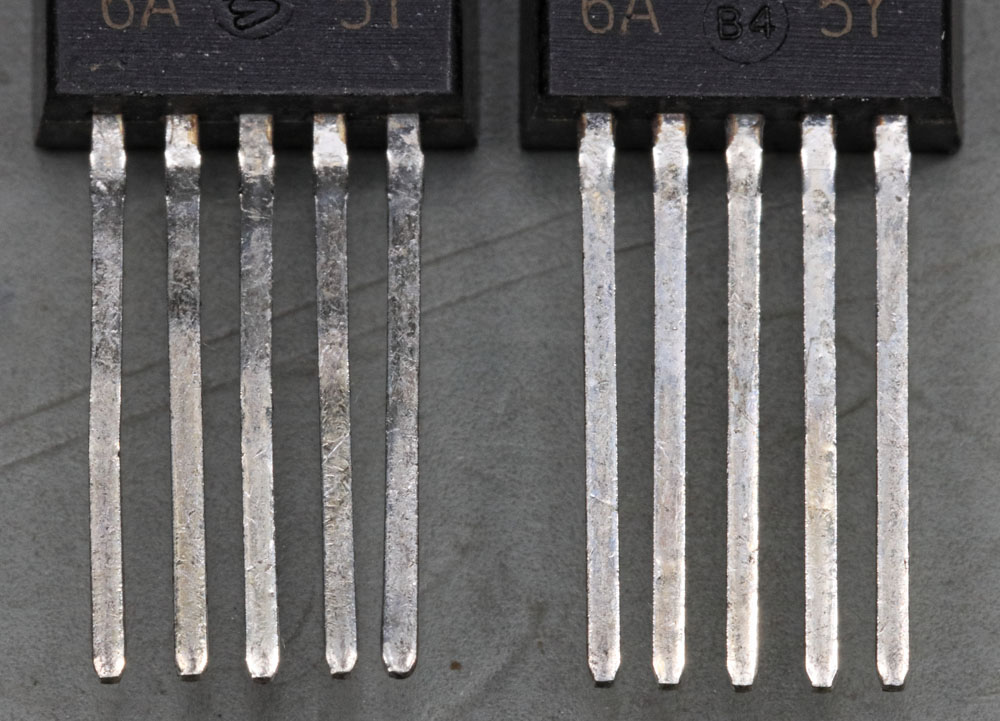

On closer inspection, the pins of the MOSFETs are noticeably bent. However, they still appear to be the original pins. In case of used components, new pins are sometimes fitted directly under the package.

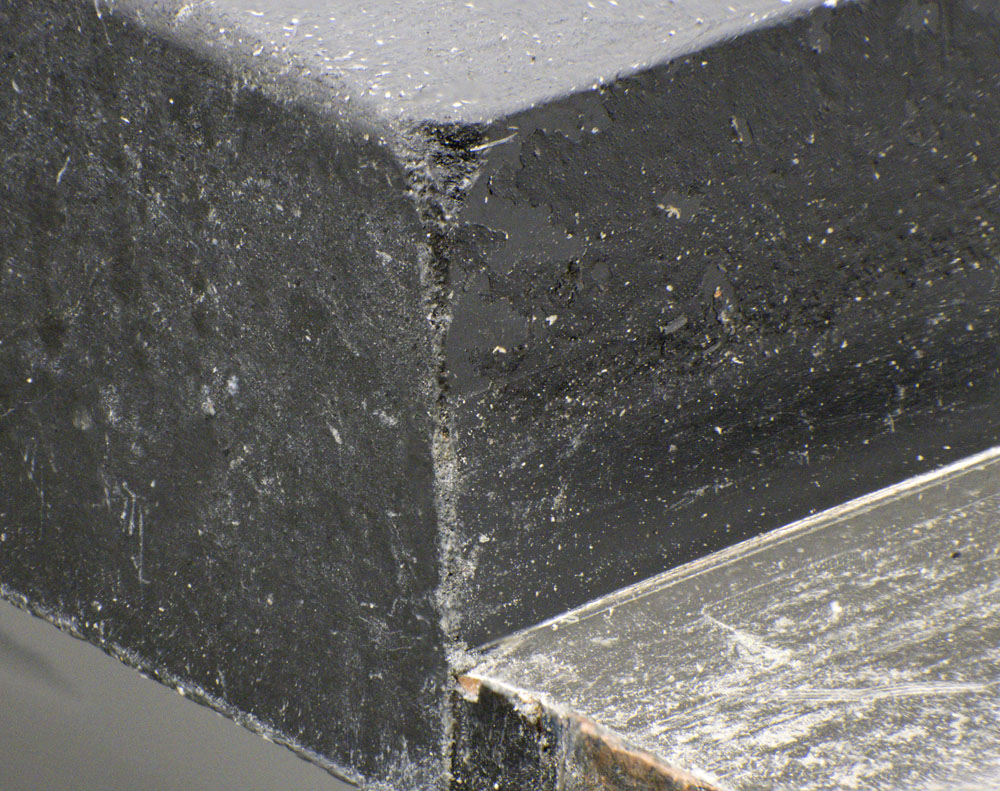

Knowing that it is a fake, you can recognise the grooves on the surface that were created when the case was sanded down. However, they are not overly noticeable. The indentation with the letter M, on the other hand, is more conspicuous. The indentation is shallower in the upper area than in the lower area. Here you can also recognise the original structure of the surface.

Looking from the side, it becomes even clearer that these are fakes. Apart from the fact that one corner of the case is broken off, you can see the layer of lacquer that was applied to the sanded package.

The underside of the package is noticeably dirty.

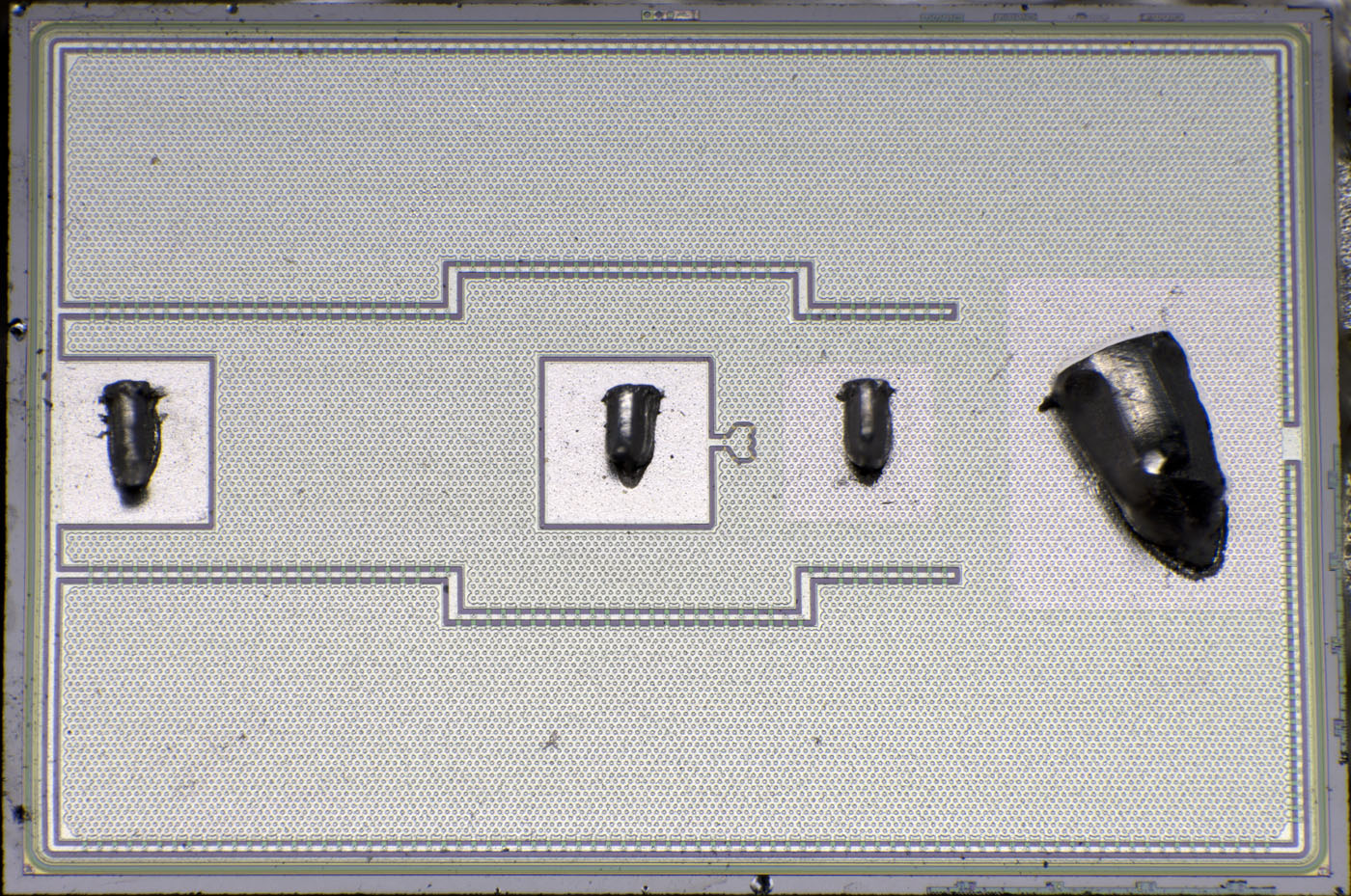

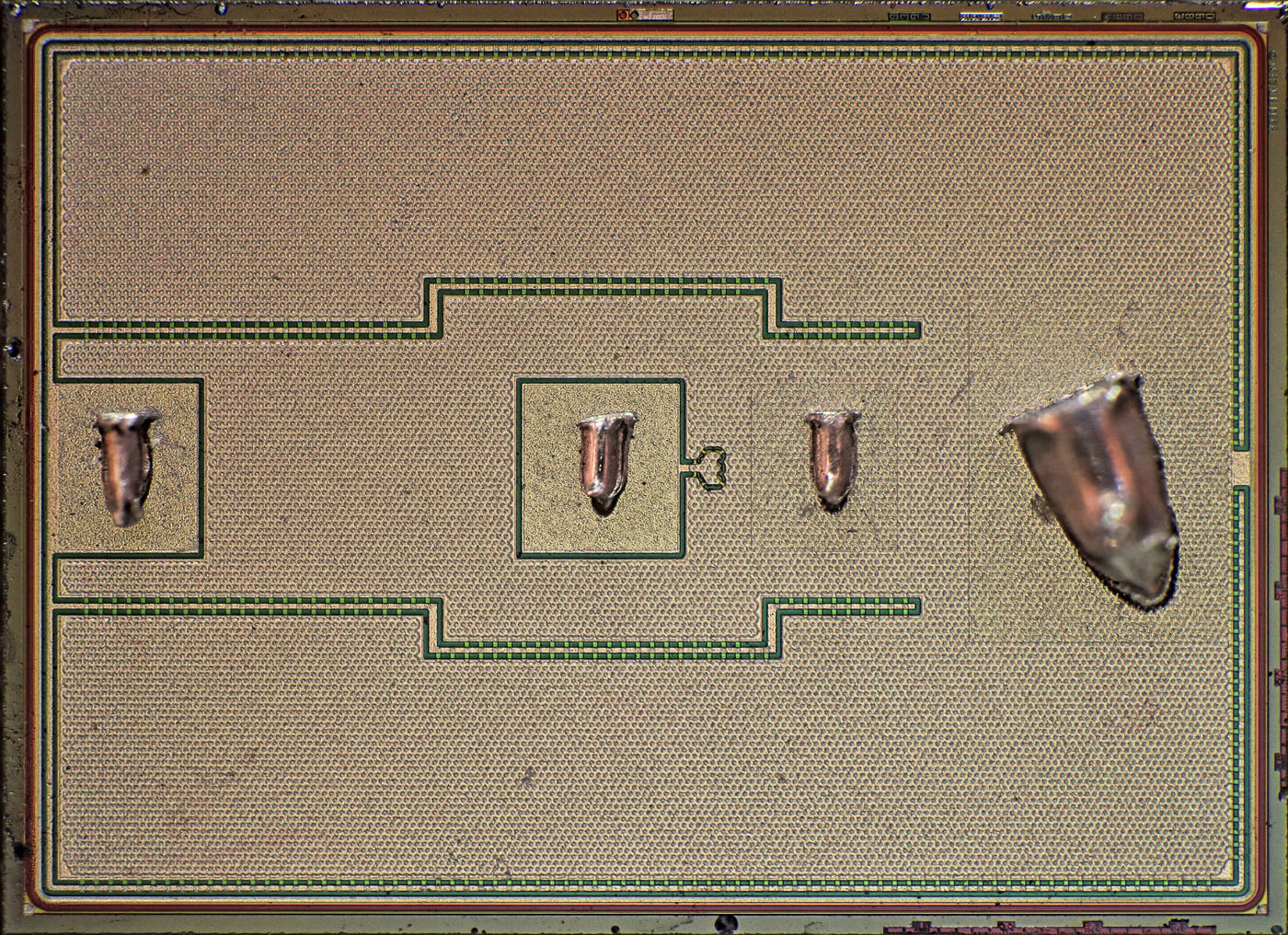

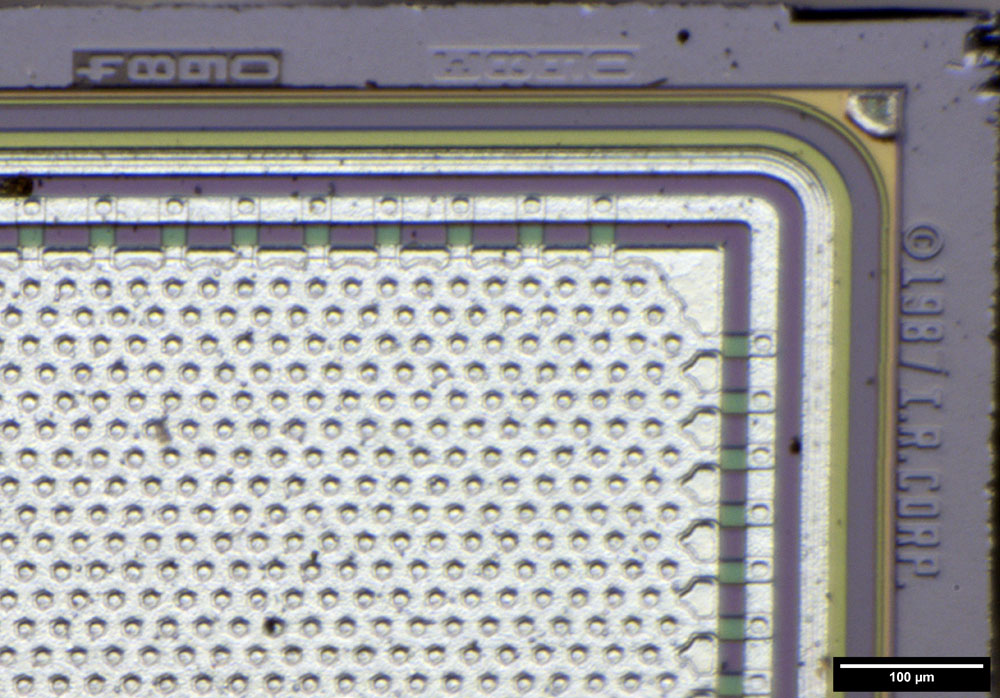

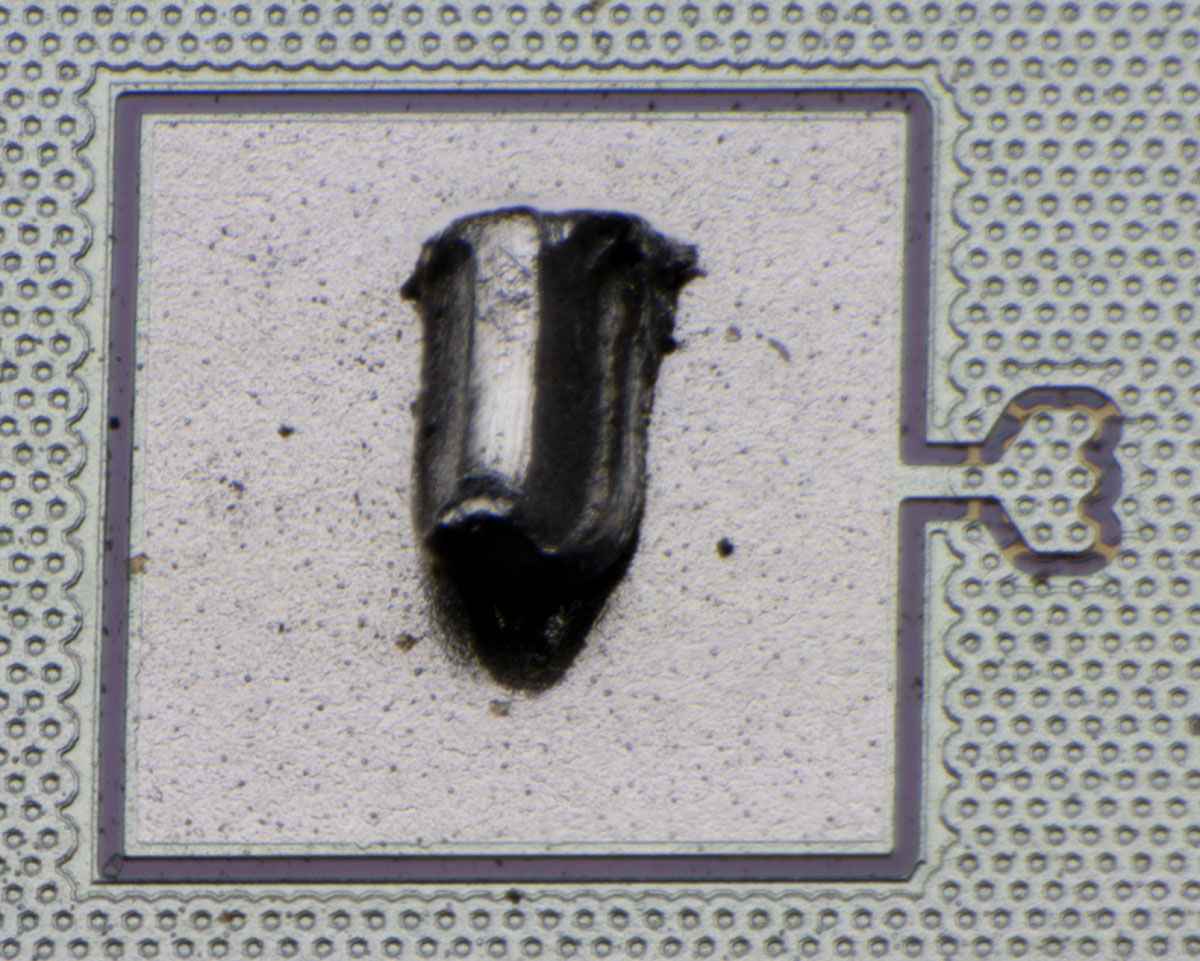

The package contains a die with an edge length of 4,6mm x 3,3mm.

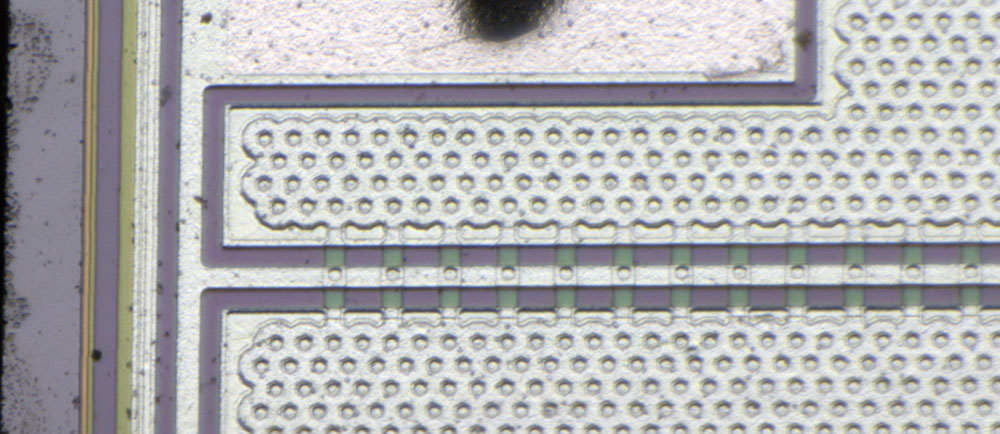

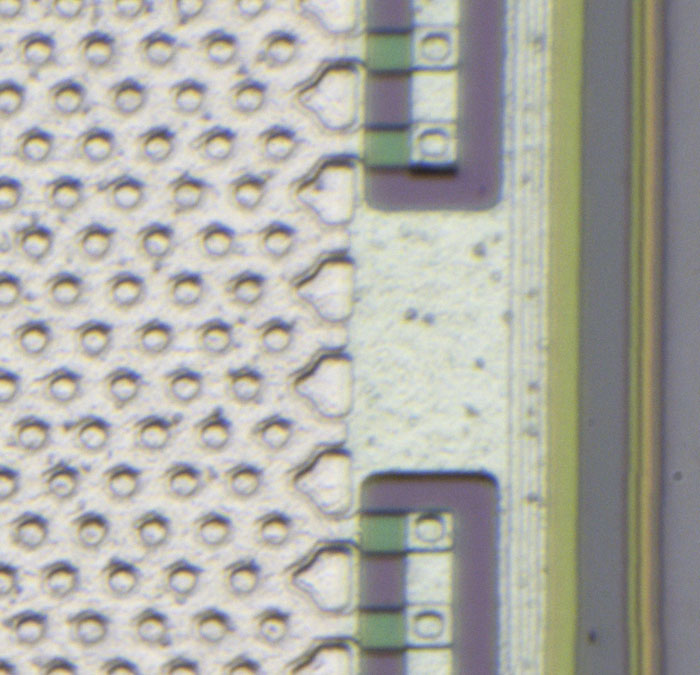

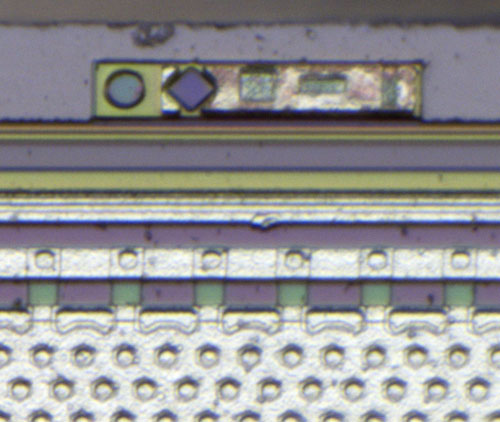

As usual with a MOSFET, the large metal surface represents the source potential. The gate potential is contacted on the left and gets distributed into the surface of the transistor via a surrounding frame and two stubs. The source contact for current measurement is located in the centre of the die. To the right, the Kelvin contact allows an unloaded contacting of the source potential. The International Rectifier Application Note 959B emphasises that it is important for good current measurement that the Kelvin contact is placed close to the bondpad for current measurement.

Here it becomes clear that these are counterfeit parts. The International Rectifier Application Note 964D shows how the different HEXFET generations are constructed. Both the dimensions and the structures correspond to those of a HEXSense-3 MOSFET with a reverse voltage of 60V. It was therefore originally an IRCZ34. The IRC540, a HEXSense-4 MOSFET with a dielectric strength of 100V, would have a significantly different structure and the die would be 1mm longer in both width and length.

The IRCZ34 shows typically a slightly lower impedance than the IRC540 (50mΩ / 77mΩ) and allows a slightly higher current flow (30A / 28A). However, with 60V the dielectric strength of the IRCZ34 is significantly lower than the 100V of the IRC540. In an application designed for the IRC540, the forgery would fail quickly.

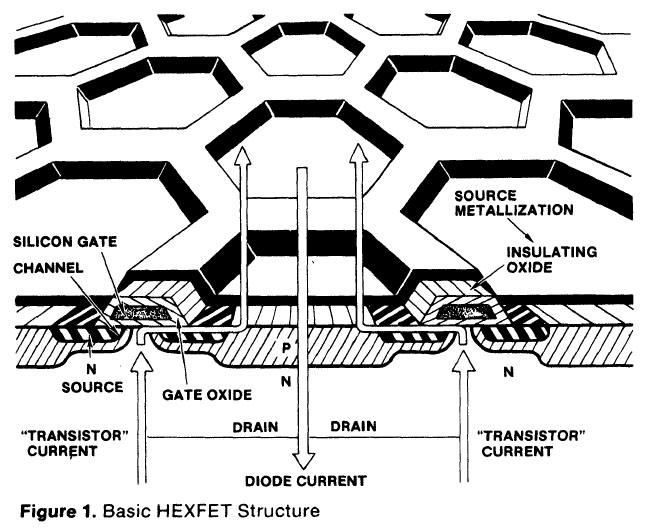

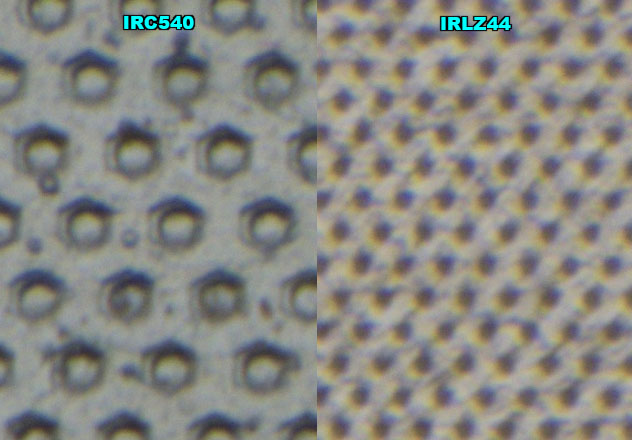

The typical hexagonal structures of HEXFETs were already recognisable in the overview. The International Rectifier HEXFET Databook shows how the structures are organised in detail.

As is usual with MOSFETs from International Rectifier, some masks are shown on the upper edge. On the right is the copyright and a reference to the year 1987.

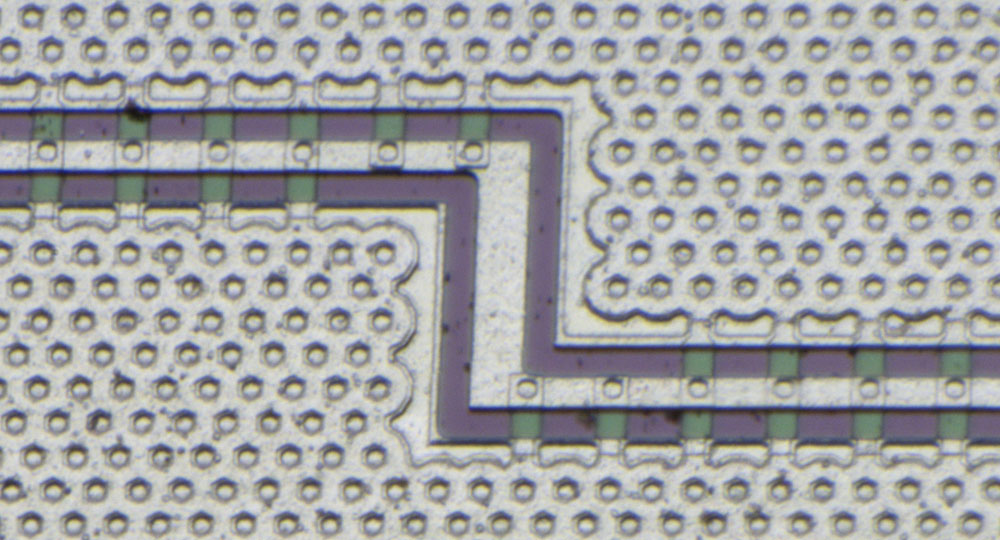

The contacts of the individual MOSFETs can be seen through the metal layer. The distance from centre to centre is approximately 24µm. The gate potential, which surrounds the contacts and thus controls the current flow, is fed in at the side.

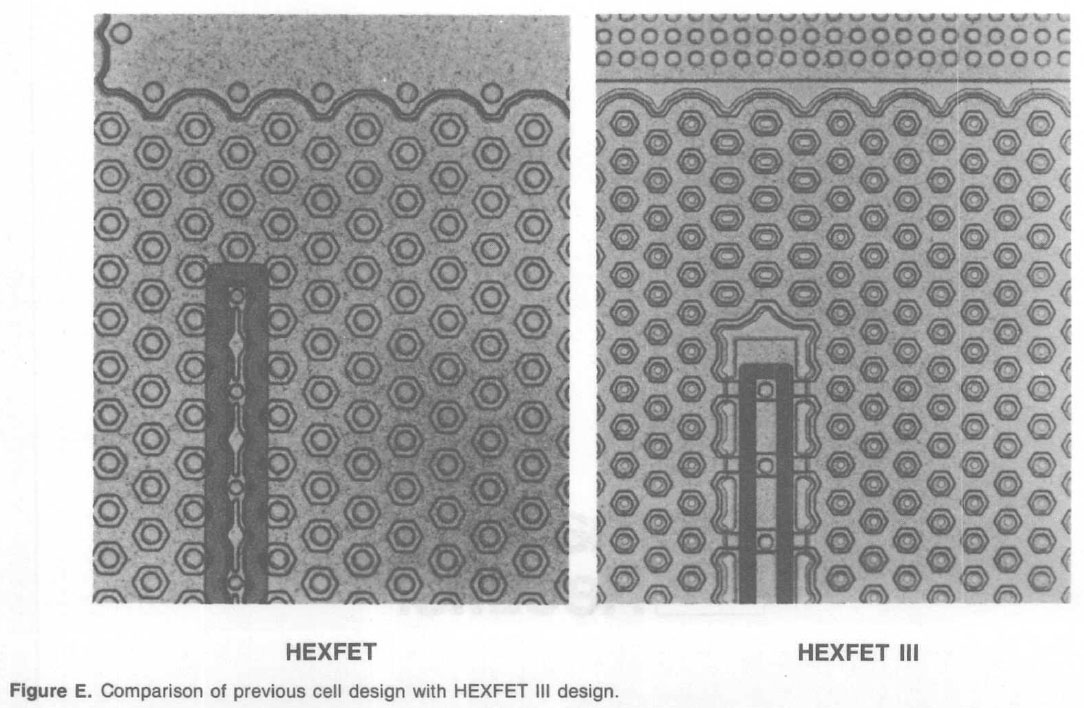

The International Rectifier Application Note 966A contains a detailed picture of the structures of the third HEXFET generation. Compared to the previous design, the structures have become slightly smaller.

The structures in the IRLZ44N are even smaller (

https://www.richis-lab.de/FET38.htm). It is probably based on the fifth generation of the HEXFETs.

It is noticeable that the gate potential is not simply conducted into the active area with the lowest possible impedance. In contrast to the right edge, at the left edge there are no connections at all to the metal layer with the gate potential. Where the gate line describes a step, the gate potential has also only been connected to the active area at selected points. The steps were apparently created due to the current sense bondpad, under which there are no active structures.

The source potential is connected to the frame at the right edge. There is probably some potential control there in order to optimise the electric field distribution.

The source contact for current measurement contacts only 12 cells. Here, too, you can see that the gate electrodes have been carefully contacted. The gate area has been broken up and only partial contacts have been integrated between the two areas.

The datasheet describes a current ratio of 1:1.410 for the two transistors of the IRCZ34, whereby the manufacturing tolerance alone is already +/-70. Added to this are the fluctuations in drain current, temperature and gate-source voltage. If we calculate with the ratio 1:1.410 and assume that the current distribution corresponds exactly to the distribution of the individual transistors, the load transistor should be constructed with 16.920 transistors. In fact, there are 18.145 transistors, which is slightly more than you would expect. The current is probably not distributed ideally and the slightly different ratio compensates for this.

A test structure is shown at the top edge, which allows the alignment of the masks to be checked against each other.

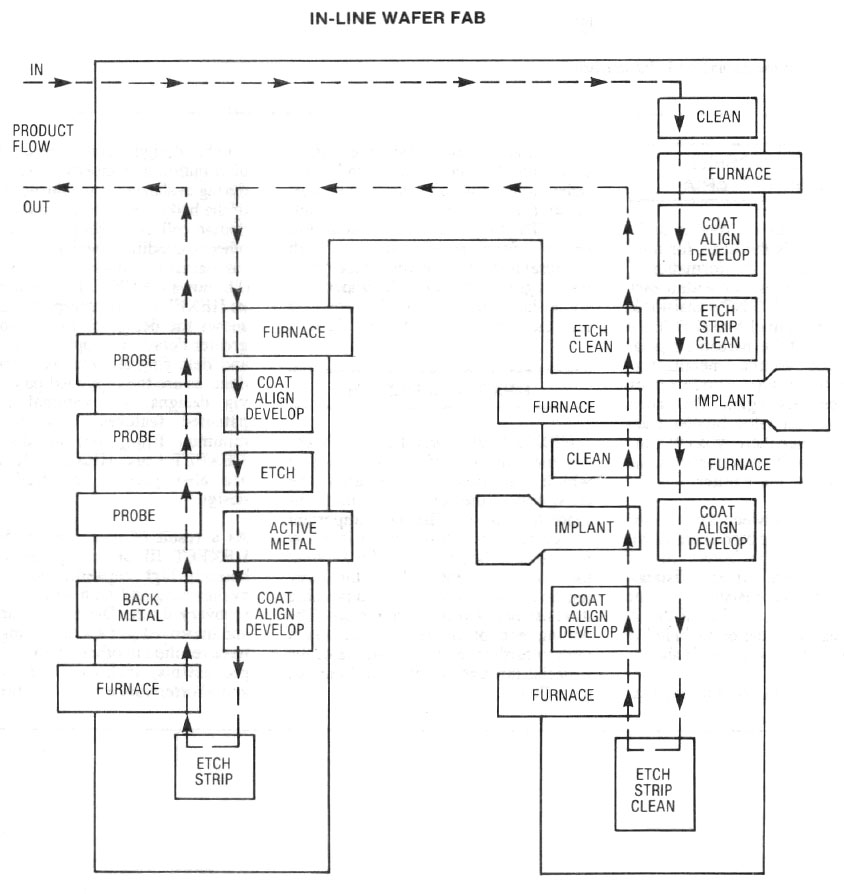

The International Rectifier Application Note 966A contains a simple illustration that provides an overview of how the HEXFET transistors were manufactured. In order to minimise production times, a production line has been set up that the MOSFETs can pass through in a linear fashion, which is otherwise rather unusual in the semiconductor industry.

https://www.richis-lab.de/FET39.htm