21

Projects, Designs, and Technical Stuff / Re: Homebrew Lock-In Amplifier

« Last post by RoGeorge on Today at 05:41:35 am »A few measures to lower the noise:

- keep the breadboard wires short and the loops short. A circular shape is the largest area a string can enclose, and the larger the area of a loop, the more induced noise. If the breadboarding wires are too long, then run them parallel, or twisted. Preferably cut the wires just the right length, and run then as if it were a PCB (for example use single core wires stripped from a LAN patch cord, and cut them on the spot, just the right length, LAN wires are made of copper, and thick enough for the breadboard contacts).

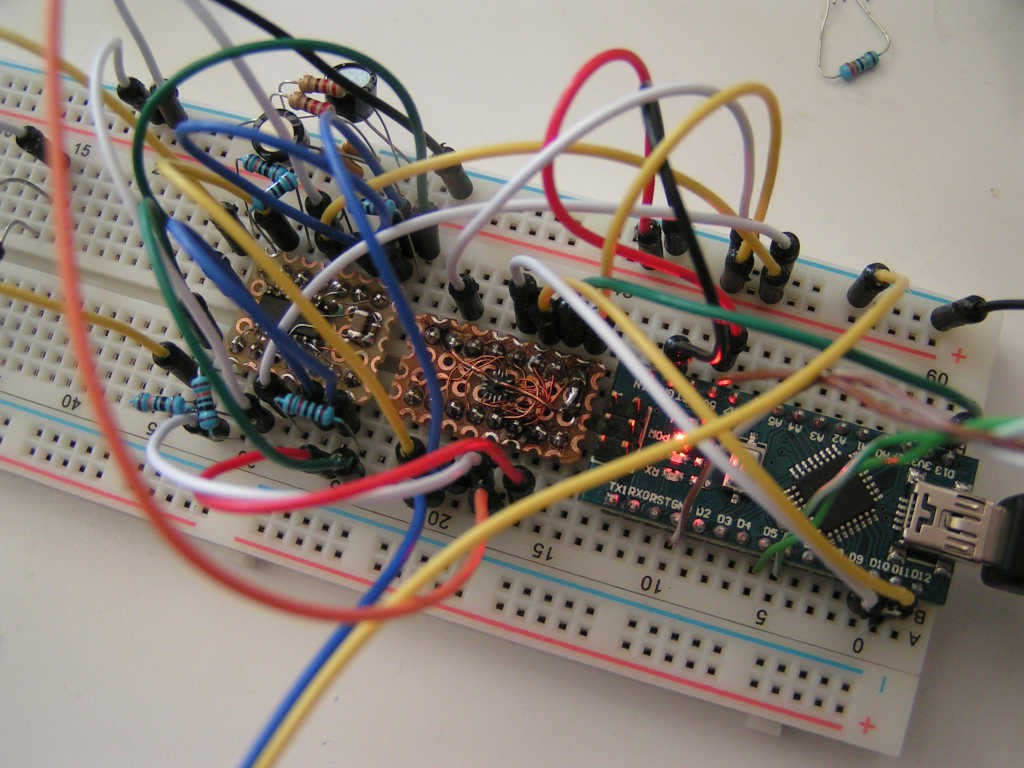

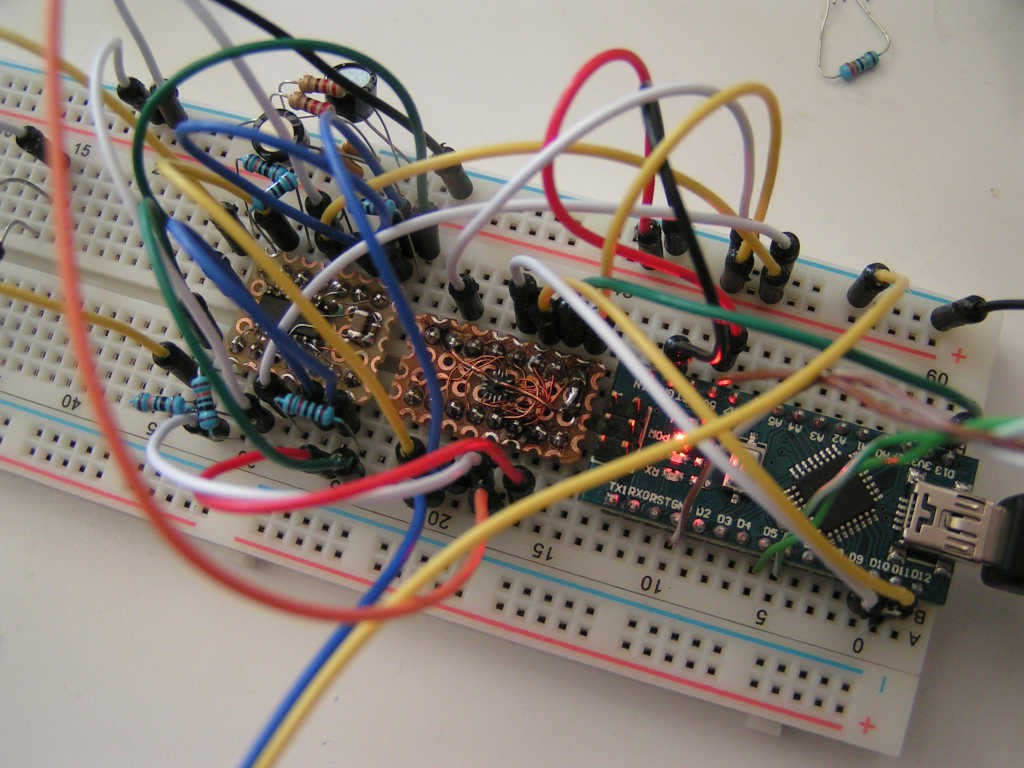

Not so good (wires making loops with big area, components with long legs also making loops):

Better (wires were cut just the right length and routed straight, components terminals not very long):

Well, maybe the capacitors and resistors terminals could have been cut even shorter, like here: https://www.eevblog.com/forum/projects/t20347/?action=dlattach;attach=1242762;image but you got the idea, avoid big area loops.

- avoid ground loops. Use star-connection for GND wires, with a single GND point from where all the ground wires are leaving to different places in the circuit. Do not chain the GND wires one after another. A single GND point also separates the analog and digital GNDs.

- if the above is not possible in practice, at least keep the analog and digital current loops separated:

https://www.analog.com/media/en/training-seminars/tutorials/MT-031.pdf

https://www.analog.com/media/en/technical-documentation/application-notes/AN-202.pdf

- enclose the low signal stages in a grounded metal shield, shielding makes a big difference, it eliminates the noises induced from the outside of the circuit

- keep the breadboard wires short and the loops short. A circular shape is the largest area a string can enclose, and the larger the area of a loop, the more induced noise. If the breadboarding wires are too long, then run them parallel, or twisted. Preferably cut the wires just the right length, and run then as if it were a PCB (for example use single core wires stripped from a LAN patch cord, and cut them on the spot, just the right length, LAN wires are made of copper, and thick enough for the breadboard contacts).

Not so good (wires making loops with big area, components with long legs also making loops):

Better (wires were cut just the right length and routed straight, components terminals not very long):

Well, maybe the capacitors and resistors terminals could have been cut even shorter, like here: https://www.eevblog.com/forum/projects/t20347/?action=dlattach;attach=1242762;image but you got the idea, avoid big area loops.

- avoid ground loops. Use star-connection for GND wires, with a single GND point from where all the ground wires are leaving to different places in the circuit. Do not chain the GND wires one after another. A single GND point also separates the analog and digital GNDs.

- if the above is not possible in practice, at least keep the analog and digital current loops separated:

https://www.analog.com/media/en/training-seminars/tutorials/MT-031.pdf

https://www.analog.com/media/en/technical-documentation/application-notes/AN-202.pdf

- enclose the low signal stages in a grounded metal shield, shielding makes a big difference, it eliminates the noises induced from the outside of the circuit

Recent Posts

Recent Posts