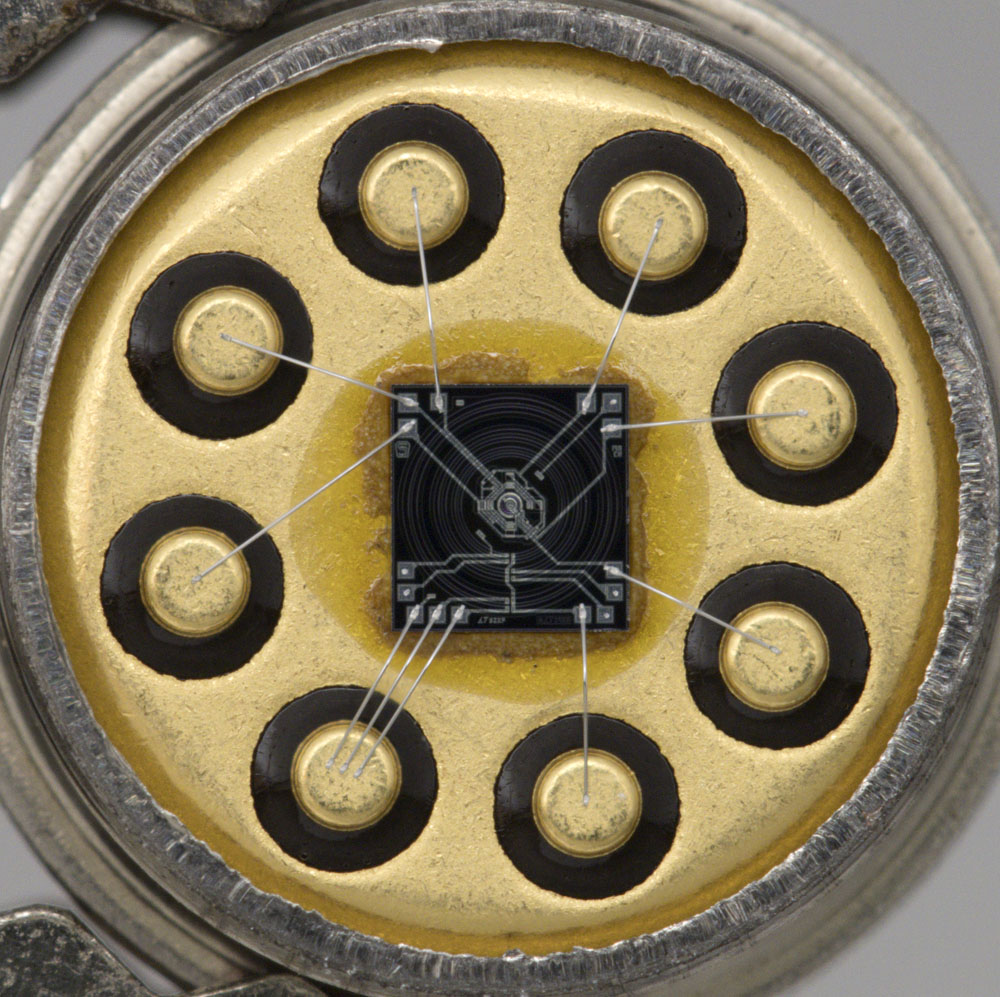

Now here we have the TLZ1000A. The LTZ1000 has a thermal resistance of 80K/W. The LTZ1000A has a thermal resistance of 400K/W.

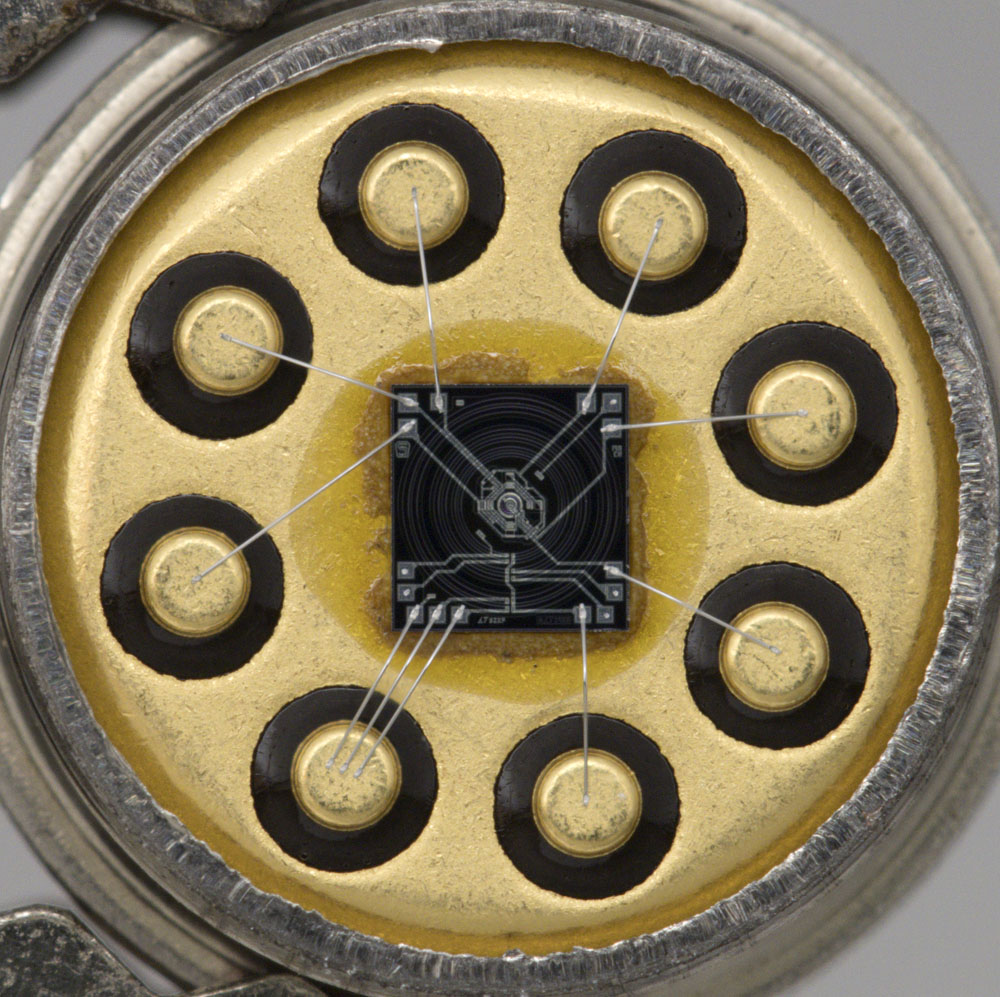

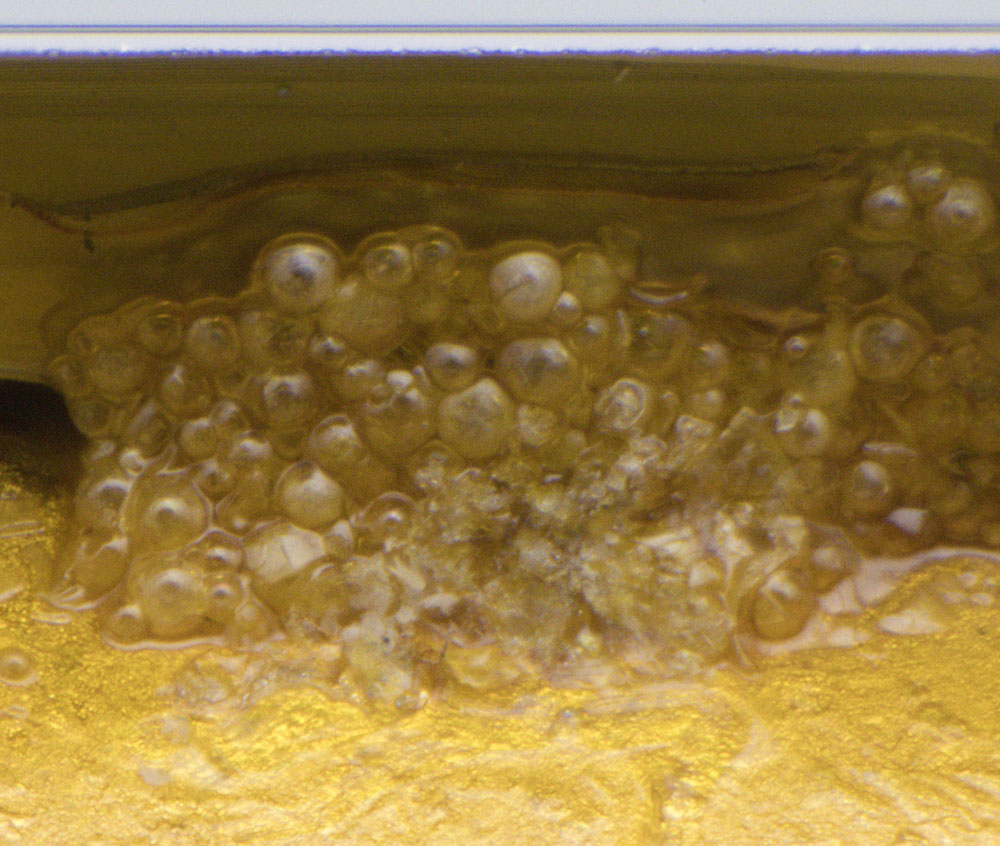

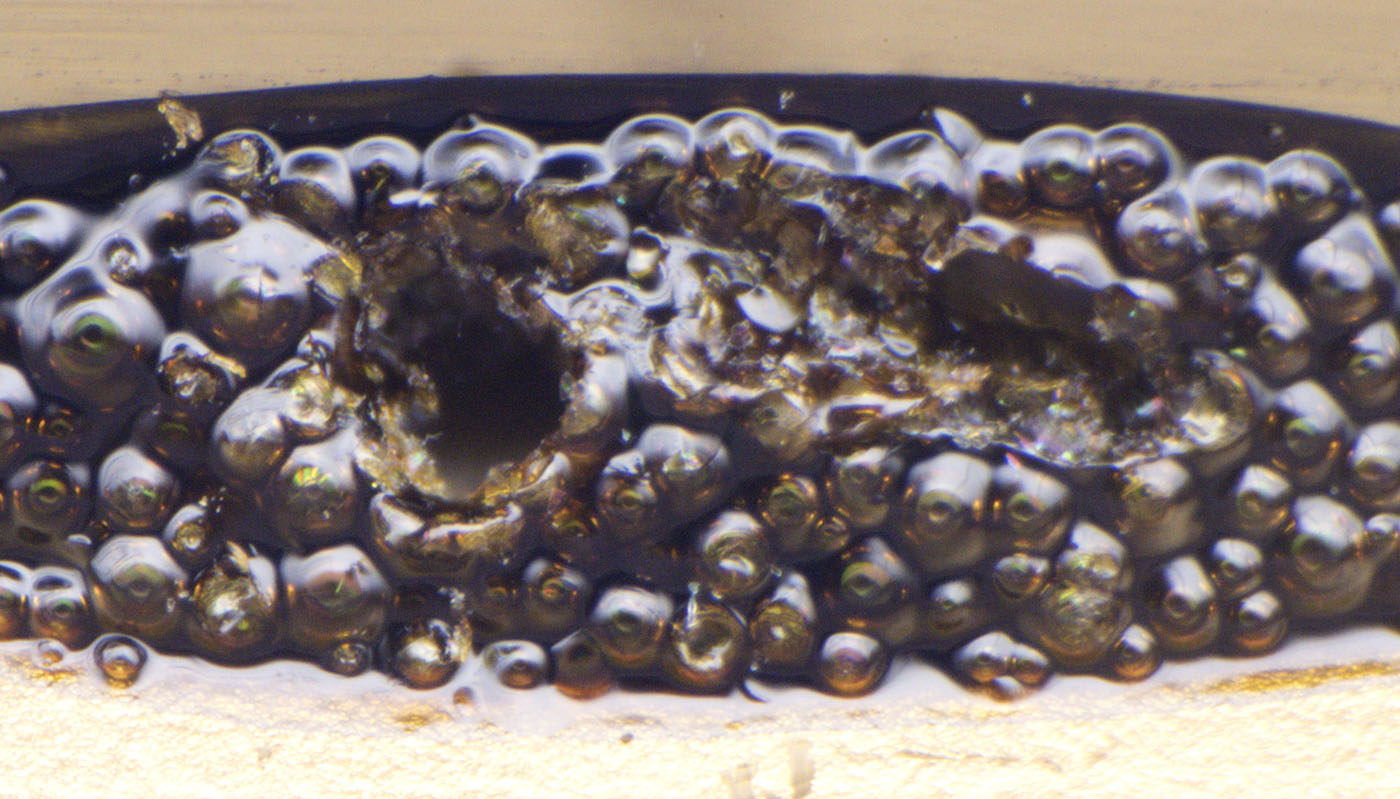

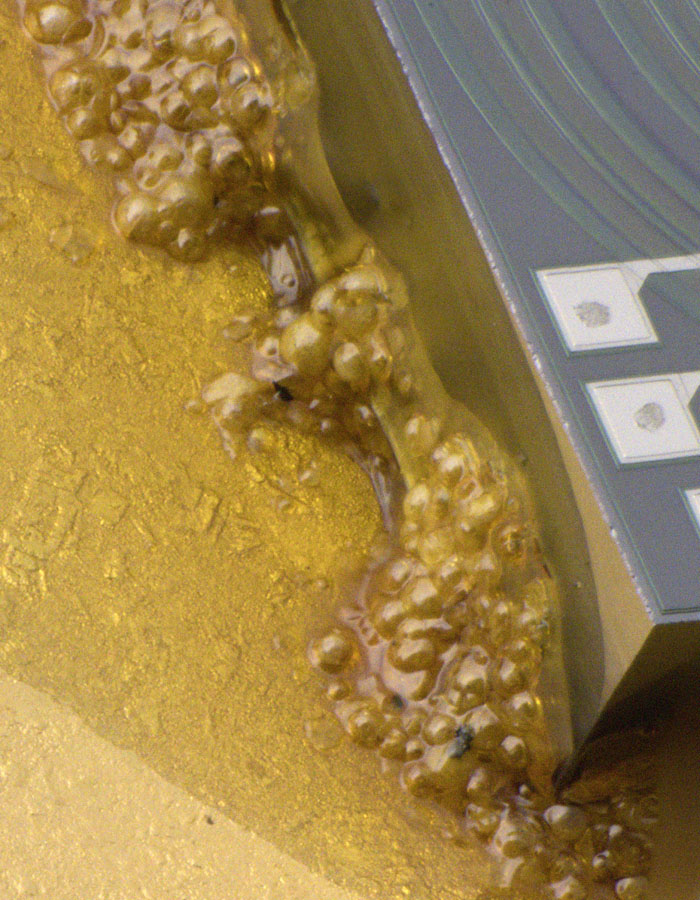

The LTZ1000A has the same basic design as the LTZ1000. Only the die attach material has changed. Here you can already see that the material is surprisingly unevenly distributed.

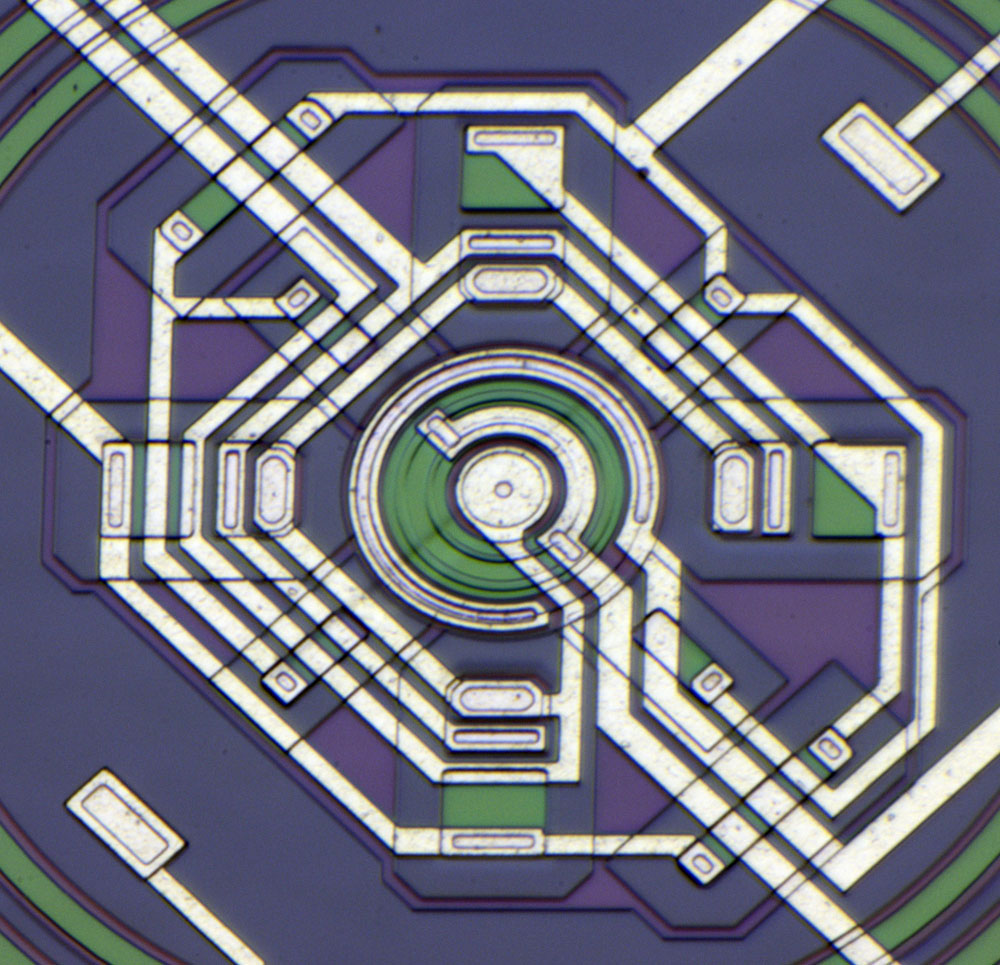

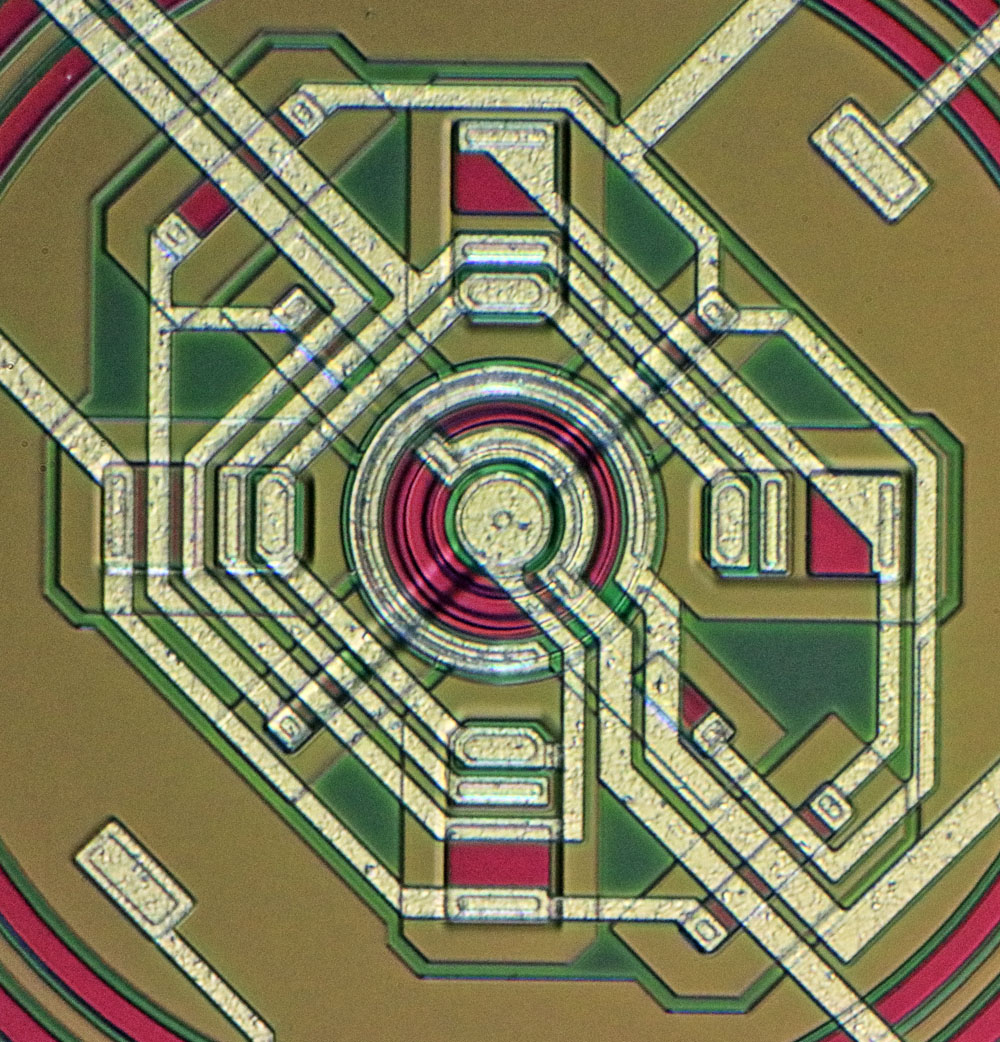

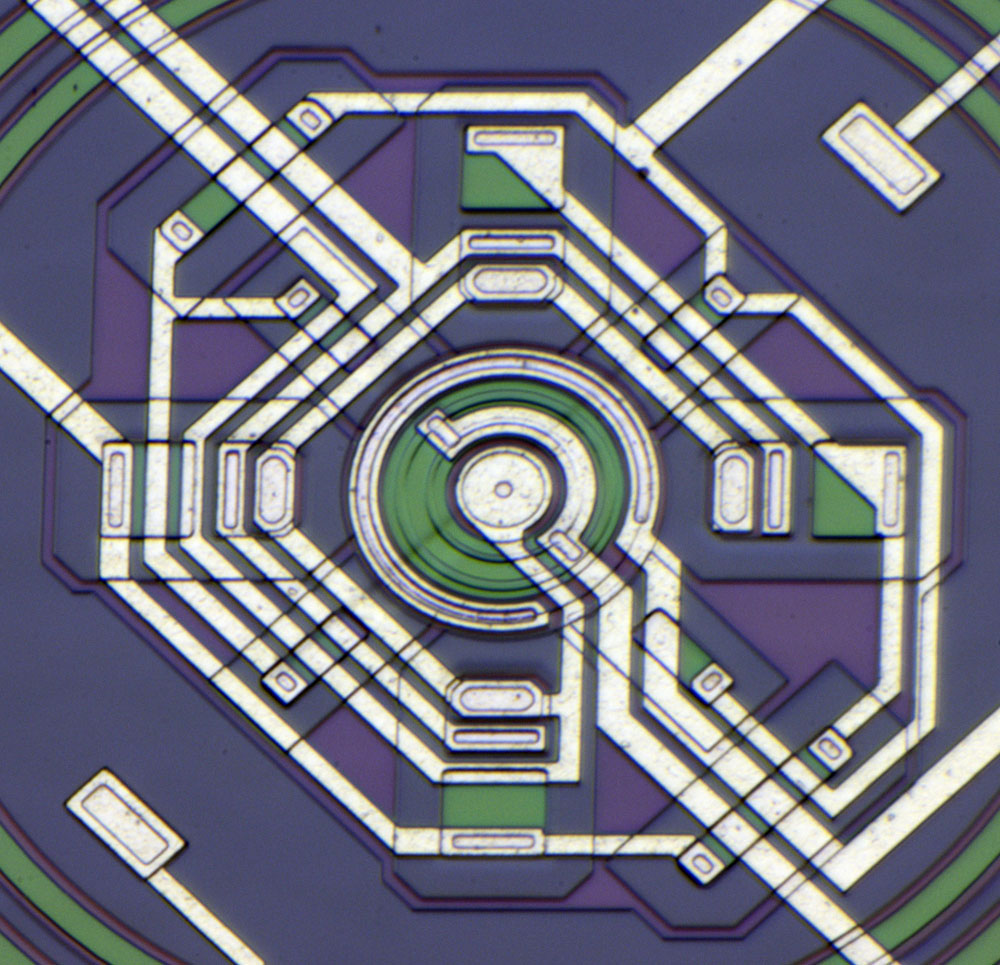

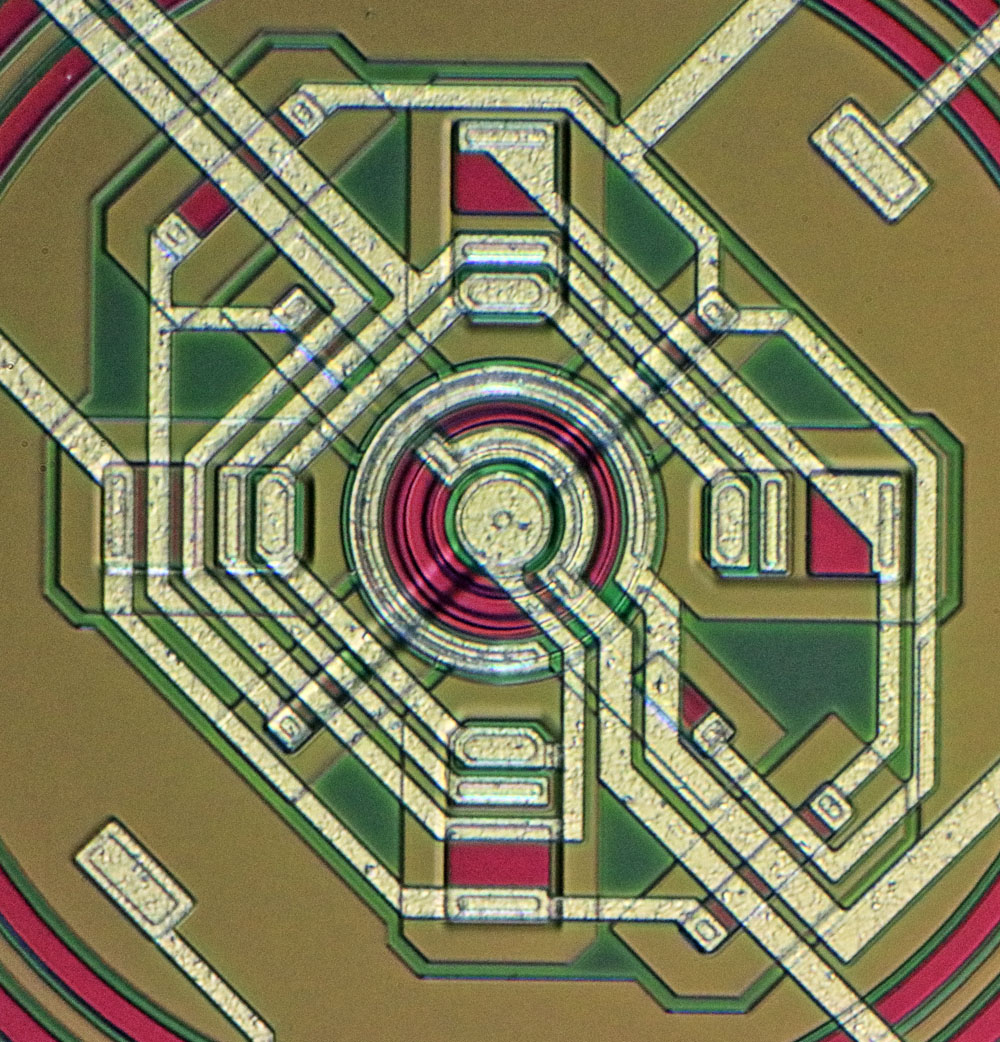

The LTZ1000A shows the datecode 4322, but the design is still the same as it was in 1983. Apart from the fact that the colors are slightly different in this illustration, it is the same design as in the LTZ1000. This was to be expected, as the only difference between the two variants is the heat transfer resistance.

Also in detail there are no differences to the LTZ1000.

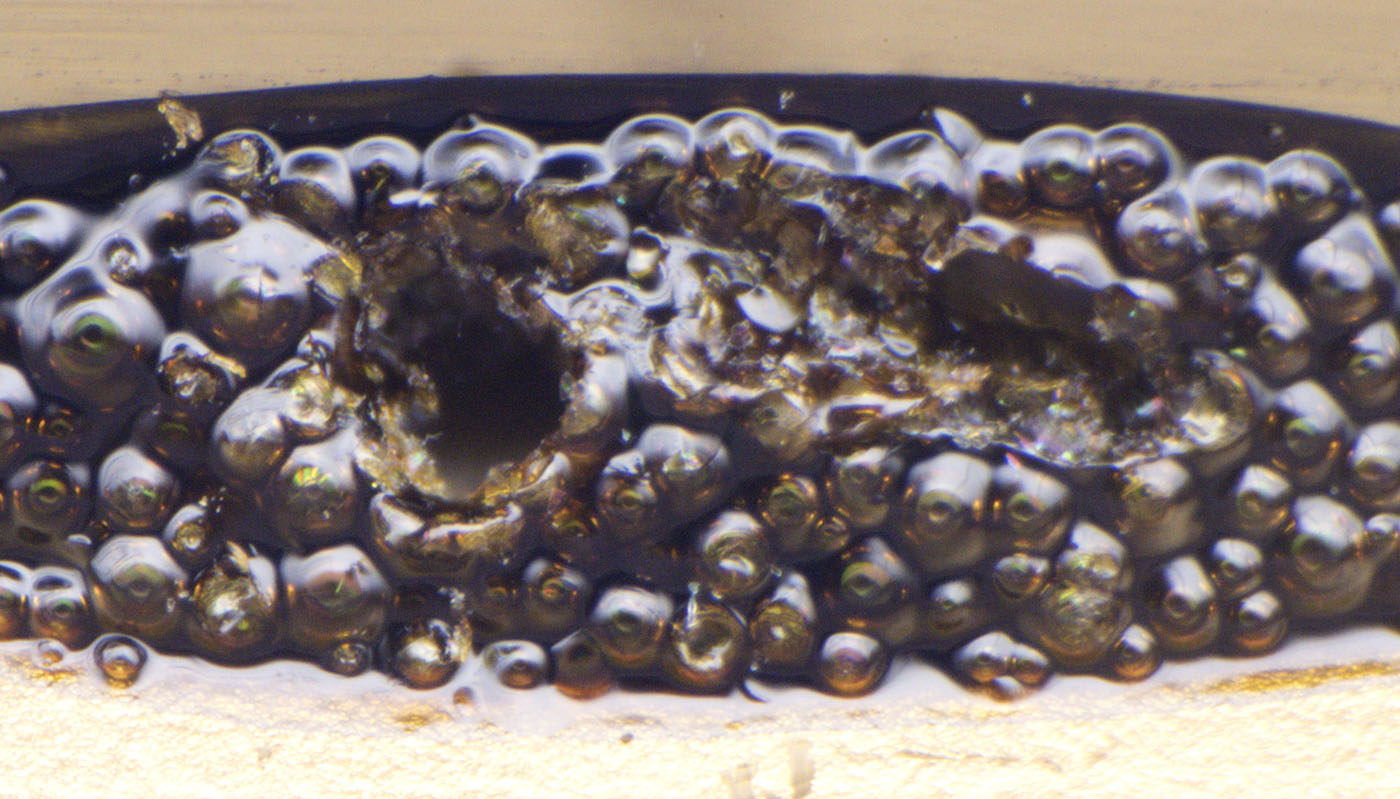

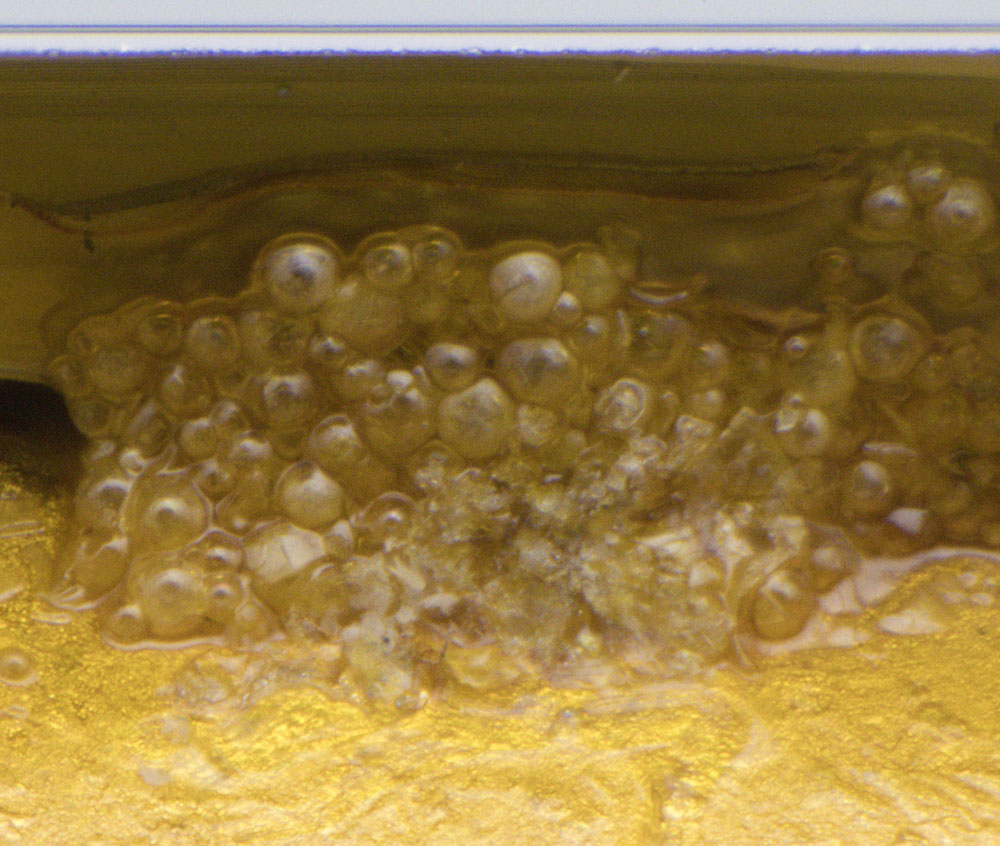

The material used as die attach contains glass beads. The glass beads ensure a certain distance between the housing and the silicon, which increases the thermal resistance. The very similar ADR1000 (

https://www.richis-lab.de/REF19.htm) also has a special die attach, but this is finely granular. It obviously insulates somewhat less well, as a heat resistance of 216K/W is specified for the ADR1000 (LTZ1000A: 400K/W). The ADR1001 (

https://www.richis-lab.de/REF29.htm) uses a similar material to the LTZ1000A. In the LT1088 RMS converter (

https://www.richis-lab.de/LT1088.htm), which is based on the design of the LTZ1000, air bubbles ensure good thermal insulation.

LT1088

I have stabbed the die attach of the LT1088. You can destroy it really easy. These are air bubbles!

/LT1088

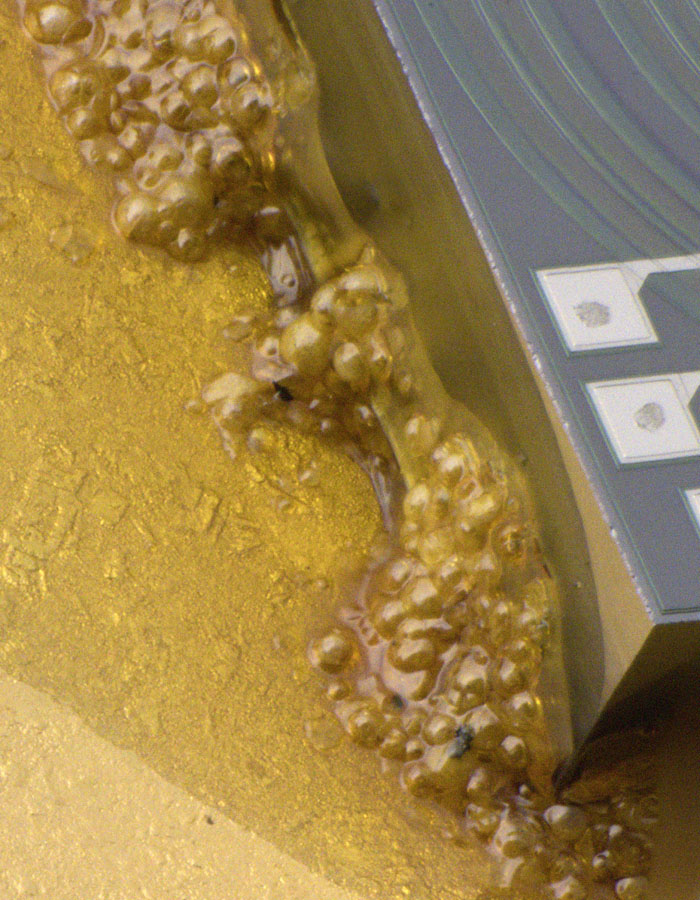

The PCN 23_0011 shows which glass beads are used in the LTZ1000A. It describes that the glass beads will be changed from “Z-LIGHT Glass Sphere” to “COSPHERIC Glass Sphere” on 14.7.2023. It also states that the new glass beads will have a diameter of 90 - 106 µm. The glass beads in this LTZ1000A appear to be much less well sorted. In addition to the large beads, there are also many small particles in the mass.

If you scratch over the die attach of the LTZ1000A you get just some scratches. It´s hard, it´s glass.

The uneven distribution of the die attach is surprising. This LTZ1000A was purchased from Mouser, so it is almost certainly not a rejected part.

There are even holes under the die. Since a high thermal resistance is desired, one might think that cavities are not a disadvantage. However, it is important to remember that the LTZ1000A is a precision component. An inhomogeneous connection to the housing could lead to an inhomogeneous temperature distribution in the die. It is also conceivable that thermomechanical stresses could arise. The influence of a cavity is certainly small, but can be relevant for a precision component.

https://www.richis-lab.de/REF44.htm

Recent Posts

Recent Posts