1

Projects, Designs, and Technical Stuff / Re: Opamps - Die pictures

« Last post by magic on Today at 07:43:37 am »Nice. This chip still looks quite simple for what it is doing.

The output of the chopper feeds gm4 and gm5, which provide additional gain. And the whole chopper is bypassed at frequencies near the chopping frequency and above in order to reduce aliasing artifacts and achieve GBW much higher than the chopping frequency.

Of course the "auto zero" explanation about gm3 canceling gm1 offset voltage and a bunch of sample-and-hold circuits making it all work is valid too. I'm not sure what the difference between "chopper stabilized" and "auto zero" is supposed to be, and if there is any real difference at all. Maybe it's only marketing talk.

I suppose it works out cheaper than designing a quad die and disabling half of it for the dual

Hmm, how far are you from a complete transistor level schematic of this opamp?

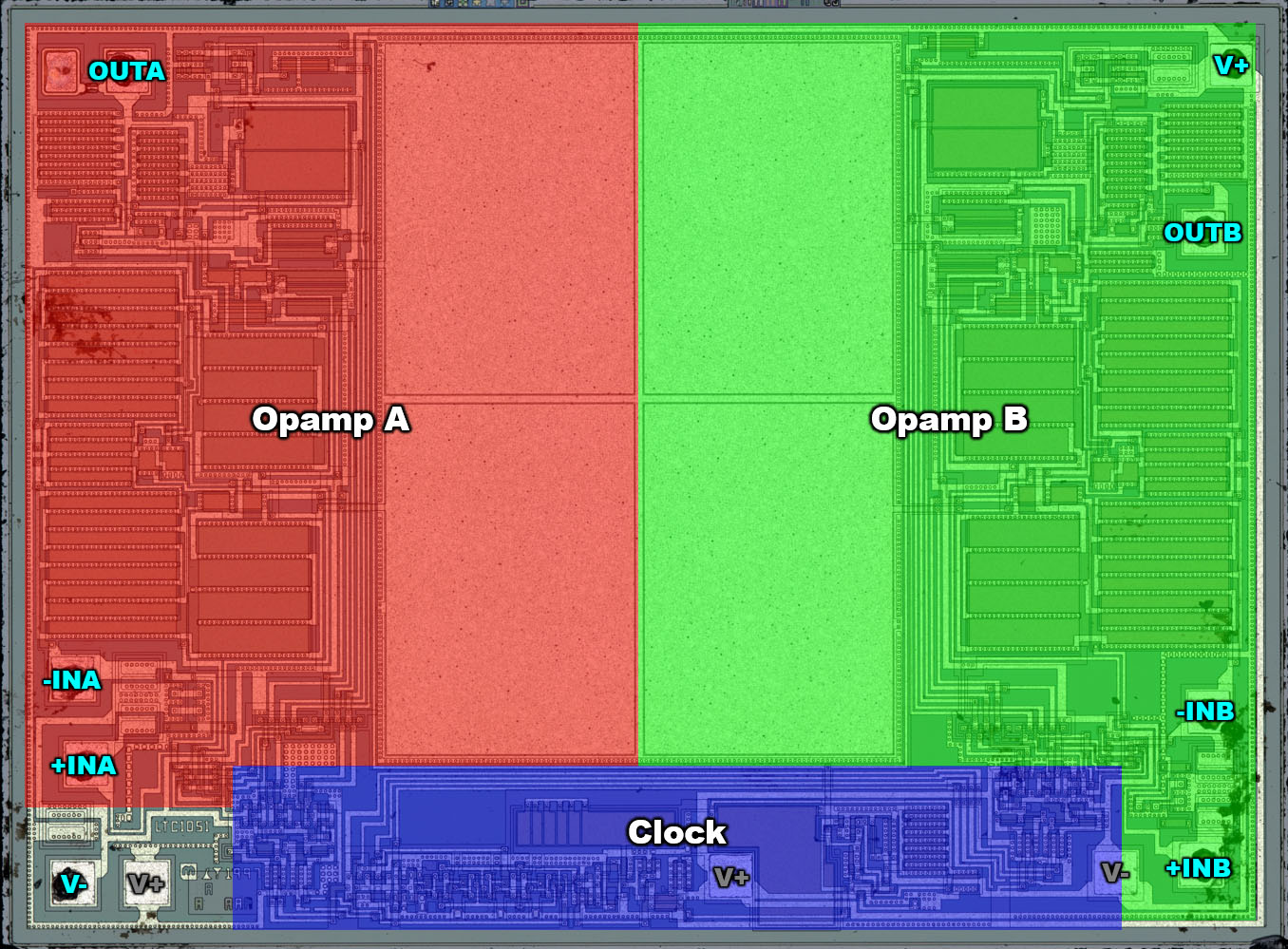

This shows that the TLC1051 is not a chopper amplifier but an auto-zero opamp. The signal does not undergo modulation and demodulation. Instead, the current offset value is stored in a capacitor and used for correction, while another capacitor holds the current value of the signal. In addition to the auto-zero path, the TLC1051 includes a parallel path for higher frequencies. This type of opamp is referred to as "auto-zero stabilised".They describe it as "chopper stabilized", not a "chopper amp". If you think about it, the part S1, gm1, gm2, S2 is a chopper amplifier: S1 chops the differential input voltage into a square wave, the linear transistors amplify the square wave, and S2 demodulates it back into DC by sampling the peaks. To avoid differential subtraction of peaks and valleys at this point, gm3 works as a DC servo of sorts and ensures that the valleys are fixed near some internal "ground" potential.

The output of the chopper feeds gm4 and gm5, which provide additional gain. And the whole chopper is bypassed at frequencies near the chopping frequency and above in order to reduce aliasing artifacts and achieve GBW much higher than the chopping frequency.

Of course the "auto zero" explanation about gm3 canceling gm1 offset voltage and a bunch of sample-and-hold circuits making it all work is valid too. I'm not sure what the difference between "chopper stabilized" and "auto zero" is supposed to be, and if there is any real difference at all. Maybe it's only marketing talk.

It's probably same thing as with MCP6024: two dual dice can be installed together to realize a quad. The top die gets its V+ in bottom left and V- in bottom right. The bottom die is rotated 180° so its supply connections are swapped.

There are three unused bondpads in the lower area. These are additional options for connecting the supply potentials.

I suppose it works out cheaper than designing a quad die and disabling half of it for the dual

The circuit corresponds to the block diagram in the LTC1052 datasheet. The datasheet states that the amplification factors of the amplifiers gm1 and gm6 must be as equal as possible for proper function. Furthermore, these are the amplifier stages with the high amplification factors. Accordingly, these two sections are relatively large and have the same structure.These things look like PMOS differential pairs with PMOS current sources in the center of the die and NMOS current mirrors.

Hmm, how far are you from a complete transistor level schematic of this opamp?

Recent Posts

Recent Posts